Method for preparing straw-sludge composite based activated carbon

A composite matrix and activated carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of high heavy metal content, high ash content, waste of straw resources, etc., achieve high hardness, good adsorption and removal capacity, and ease The effect of environmental stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

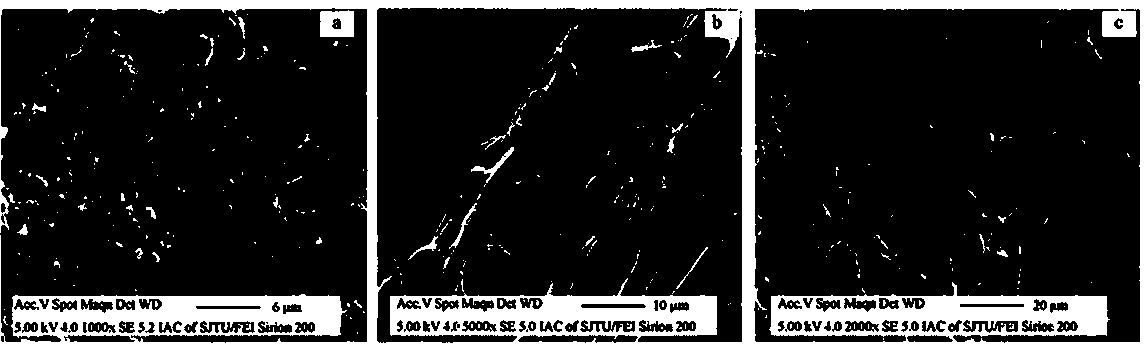

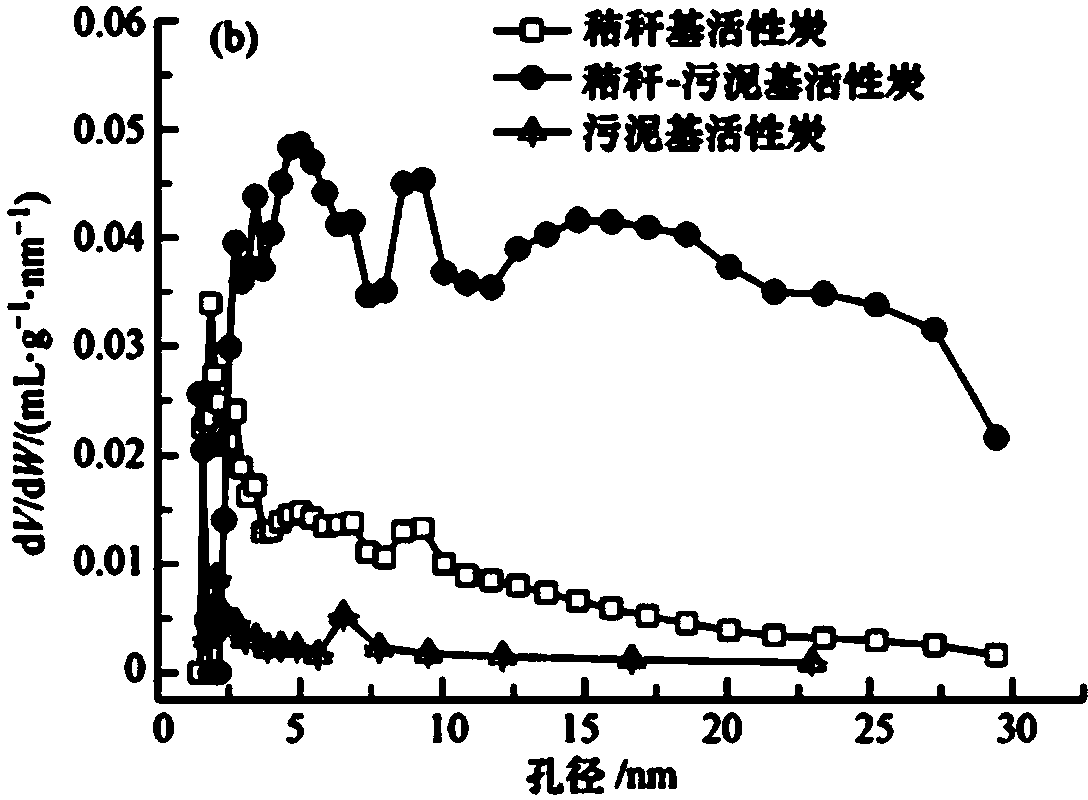

Image

Examples

Embodiment 1

[0015] Identical to embodiment 1 step, the ratio of sludge and stalks is replaced by the ratio of 1:2 and mixed, and the N of the dried sample in the resistance furnace is 2 Under the gas atmosphere, the carbonization temperature was replaced with 700°C, the carbonization time was replaced with 6h, the acidified sample S1 was impregnated with hydrochloric acid and the heating and boiling time was replaced with 60s; the sample S2 was obtained.

Embodiment 2

[0017] Identical to embodiment 1 step, the ratio of sludge and stalks is replaced by the ratio of 1:3 and mixed, and the N of the dried sample in the resistance furnace is 2 Under the air atmosphere, the carbonization temperature was replaced with 800°C, the carbonization time was replaced with 4h, the acidified sample S1 was impregnated with hydrochloric acid and the heating and boiling time was replaced with 50s; the sample S2 was obtained.

Embodiment 3

[0019] Identical to embodiment 1 step, the ratio of sludge and stalks is replaced by the ratio of 1:4 and mixed, and the N of the dried sample in the resistance furnace is 2 Under the gas atmosphere, the carbonization temperature was replaced by 600°C, the carbonization time was replaced by 2h, the acidified sample S1 was impregnated with hydrochloric acid and the heating and boiling time was replaced by 32s; the sample S2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com