Permanent gas cylinder collar applying enamel and its processing method

A processing method and permanent technology, applied in the container discharge method, container filling method, gas/liquid distribution and storage, etc., to achieve the effect of eliminating potential safety hazards, long service life, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

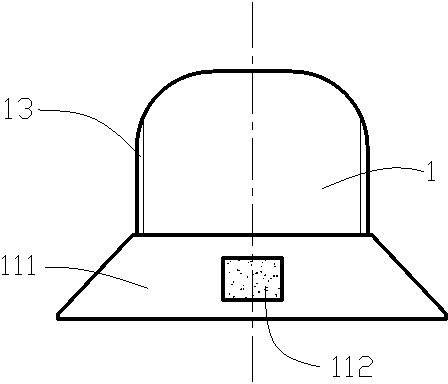

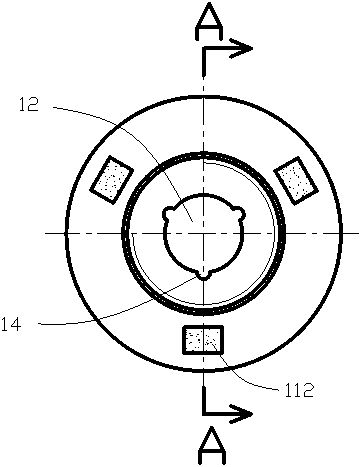

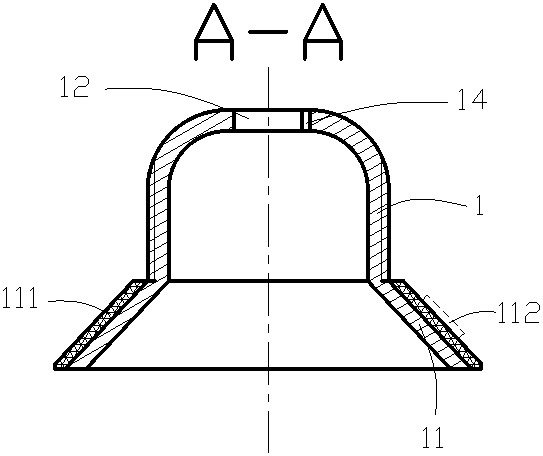

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific embodiments and related drawings.

[0032] A processing method for applying enamel to a permanent gas cylinder neck ring, comprising the following steps:

[0033] Step 1: Provide a permanent gas cylinder neck ring, and perform pre-treatment of degreasing, rust removal, neutralization and drying;

[0034] Step 2: Grinding the prepared enamel ingredients into glaze slurry, the raw material formula of the enamel includes the following components by weight:

[0035] Italian glass glaze 45~55 parts;

[0036] Quartz sand 9~11 parts;

[0037] Kaolin 2~4 parts;

[0038] Anti-fish scale explosion additive 0.5~1.5 parts;

[0039] Sodium nitrite 0.4~0.6 parts;

[0040] Borax 0.4~0.6 parts;

[0041] 30~40 parts of water;

[0042] Step 3: Use high-temperature enamel powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com