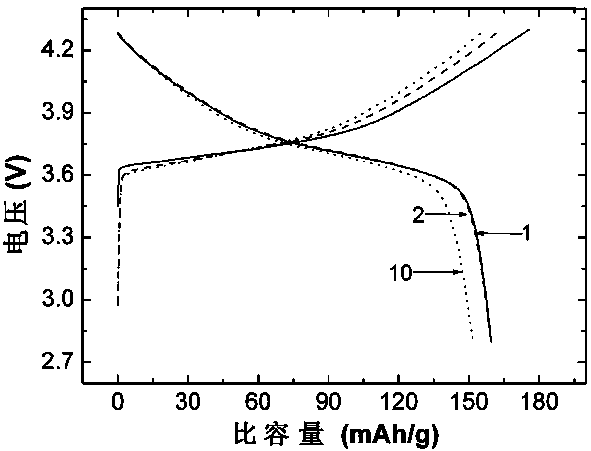

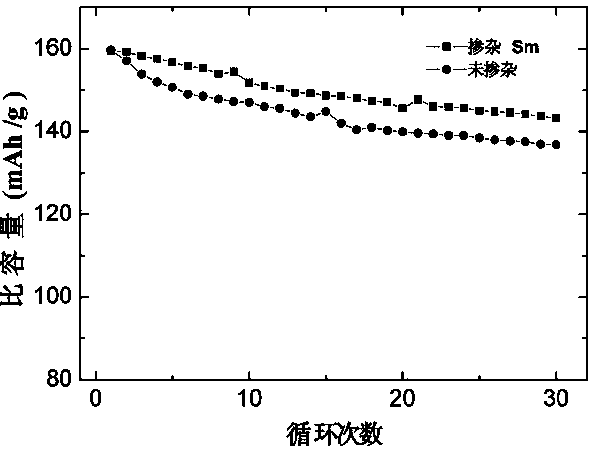

Preparation method of rare-earth samarium modified ternary anode material

A positive electrode material, rare earth technology, applied in the field of new energy materials, to achieve the effect of improving electrochemical performance, excellent electrochemical performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step (1) preparation of feed liquid: 0.2molNiSO 4 ·6H 2 O, 0.12molCoSO 4 ·7H 2 O, 0.08molMnSO 4 ·H 2 O mixed, add 400mL deionized water at room temperature to prepare a ternary ion mixture. Add 120mL of 25% ammonia water to 300mL of 4mol / L NaOH solution to form 420mL ammonia water-NaOH mixed solution.

[0030] Step (2) Co-precipitation reaction: At 20°C, evenly pour 420mL of ammonia water-NaOH mixture into the ternary mixture solution stirred at a constant speed at a flow rate of 5mL / min. After the mixed lye is added completely, seal the reaction vessel. And the stirring reaction was continued at 20°C for 2h.

[0031] Step (3) Filtration and drying: After the above reaction is completed, perform solid-liquid separation and wash with deionized water until BaCl 2 Detect the absence of SO in the wash filtrate 4 2- , the filtrate was placed in a vacuum oven and dried at 90° C. for 5 h.

[0032] Step (4) Adding samarium, distributing lithium, and high-temperature s...

Embodiment 2

[0034]Step (1) preparation of feed liquid: 0.32molNiCl 2 ·6H 2 O, 0.192mol CoCl 2 ·6H 2 O, 0.128molMnCl 2 4H 2 O mixed, and 600mL deionized water was added at room temperature to prepare a ternary ion mixture. Add 100mL of 25% ammonia water to 400mL of 6mol / L NaOH solution to form 500mL ammonia water-NaOH mixed solution.

[0035] Step (2) Co-precipitation reaction: At 55°C, add 500mL of ammonia water-NaOH mixture evenly at a flow rate of 1mL / min to the ternary mixture solution stirred at a constant speed. After the mixed lye is added completely, seal the reaction vessel. And the stirring reaction was continued at 55°C for 4h.

[0036] Step (3) Filtration and drying: After the above reaction is completed, the solid-liquid separation is carried out, and the AgNO is washed with deionized water. 3 Detection of the absence of Cl in the wash filtrate - , the filtrate was placed in a vacuum oven and dried at 70°C for 12h.

[0037] Step (4) Adding samarium, distributing lithi...

Embodiment 3

[0039] Step (1) preparation of feed liquid: 0.2molNi(NO 3 ) 2 ·6H 2 O, 0.12molCo(NO 3 ) 2 ·6H 2 O, 0.08molMn(NO 3 ) 2 (50% solution) were mixed, and 300mL deionized water was added at room temperature to prepare a ternary ion mixture. Add 150mL of 25% ammonia water to 550mL of 1mol / L NaOH solution to form 700mL ammonia water-NaOH mixed solution.

[0040] Step (2) Co-precipitation reaction: At 60°C, evenly pour 700mL of ammonia water-NaOH mixed solution into the ternary mixed material solution stirred at a constant speed at a flow rate of 100mL / min. After the mixed lye is added completely, seal the reaction vessel. And the stirring reaction was continued at 60° C. for 1 h.

[0041] Step (3) Filtration and drying: After the above reaction is completed, solid-liquid separation is carried out, washed with deionized water until neutral, and the filtrate is placed in a vacuum oven and dried at 90°C for 2 hours.

[0042] Step (4) Adding samarium, distributing lithium, and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com