Gradual change waveguide based graphene saturable absorber and preparation method thereof

A saturable absorption, graded waveguide technology, applied in the field of saturable absorber and its preparation, can solve the problems of small interaction range between light and graphene, easy to generate thermal damage, etc., achieve easy practical application, increase the fundamental mode field area , the effect of increasing the damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples. The examples provide detailed implementations and specific operating procedures, but the production of the present invention is not limited to the following implementations.

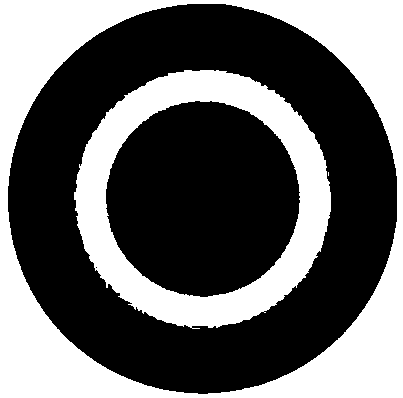

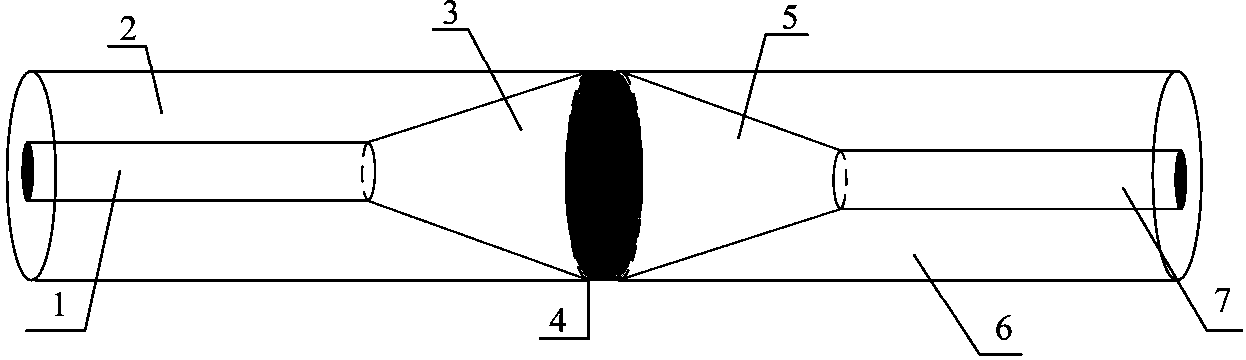

[0028] The graded waveguide is mainly prepared by using multiple electrode discharge melting technology and micro-scale grinding technology to prepare the graded waveguide. figure 1 is the cross-sectional mode field diagram of the fundamental mode propagation in the single-mode fiber, figure 2 Cross-sectional mode field diagram of the fundamental mode propagation in the proposed tapered waveguide. Depend on figure 1 with figure 2 It can be seen from the comparison that the graded waveguide can greatly increase the effective area of light and graphene film.

[0029] The following are the specific implementation steps:

[0030] Step 1. Using the multiple electrode discharge fusion technology of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com