Method for preparing reverse osmosis membrane and reverse osmosis membrane prepared by the method

A technology of reverse osmosis membrane and mixed solvent, which is applied in the direction of reverse osmosis, semipermeable membrane separation, chemical instruments and methods, etc., can solve the problems of pollution, water purification function deterioration, low efficiency of initial permeation flux, etc., and achieve improvement of permeation flux. amount, the effect of excellent desalination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The method for preparing a reverse osmosis membrane according to an embodiment of the present invention includes: (1) forming a polysulfone layer by applying a mixed solvent containing two or more solvents having different solubility parameter values to the surface of a porous support and (2) forming an active layer on said polysulfone layer.

[0025] Here, conventional porous supports known in the art can be used without limitation. For example, the porous support may be a nonwoven fabric. Materials for the nonwoven fabric may include polyester, polycarbonate, microporous polypropylene, polyphenylene oxide, polyvinylidene fluoride, and the like, but are not limited thereto.

[0026] In addition, the formation of the polysulfone layer may be performed using a solution containing a sulfonic acid group-containing polymer and a mixed solvent containing two or more solvents having different solubility parameter values.

[0027] For example, the polymer containing sulfon...

Embodiment 1

[0050] The solubility parameter value is 24.9 (J / cm 3 ) 1 / 2 ) N, N-dimethylformamide (DMF) and solubility parameter value is 26.7 (J / cm 3 ) 1 / 2 ) and dimethyl sulfoxide (DMSO) at a ratio of 90:10 to prepare a mixed solvent, then add 18 wt% polysulfone to it, and stir at 80°C for 12 hours or more to prepare a uniformly mixed liquid phase solution. This solution was cast on a nonwoven polyester fabric having a thickness of 100 μm to obtain a fabricated fabric having a thickness of 150 μm, and the resulting fabric was dipped in water to prepare a porous polysulfone support.

[0051] After the prepared porous polysulfone support was dipped into and removed from an aqueous solution containing 2 wt% m-phenylenediamine (mPD) for 2 minutes, the excess aqueous solution on the support was removed using a 25 psi roller and dried at room temperature 1 minute.

[0052] Then, the above-mentioned support body was dipped into an ISOL-C solution (SKCCorp.) containing 0.1wt% trimesoyl chlo...

Embodiment 2

[0054] A reverse osmosis membrane was prepared in the same manner as described in Example 1 except that DMF and DMSO were mixed in a ratio of 80:20.

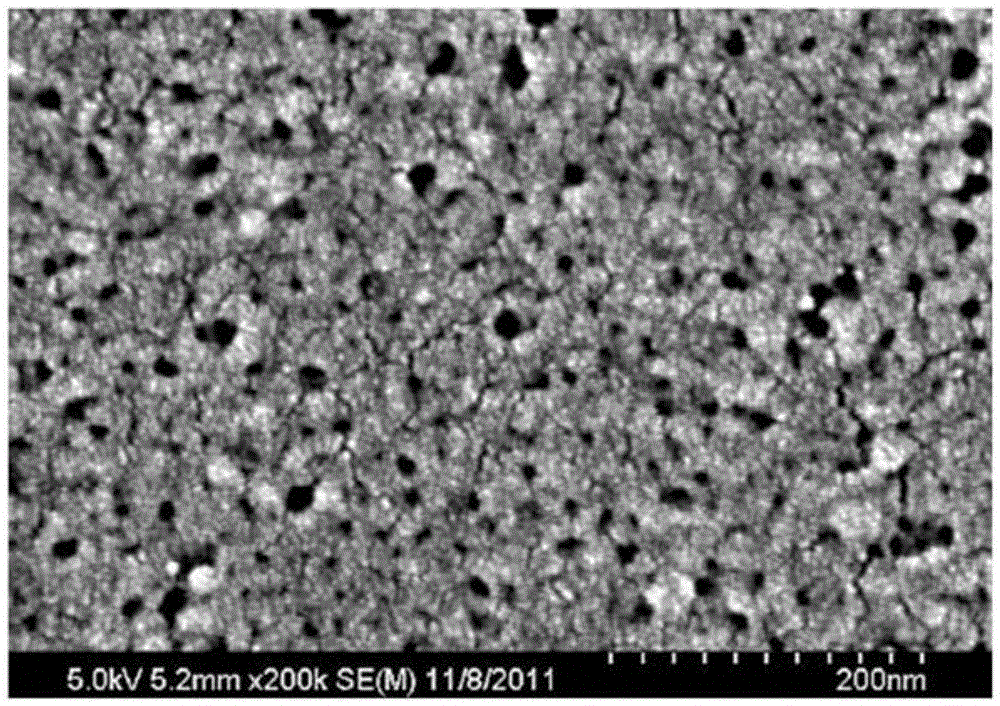

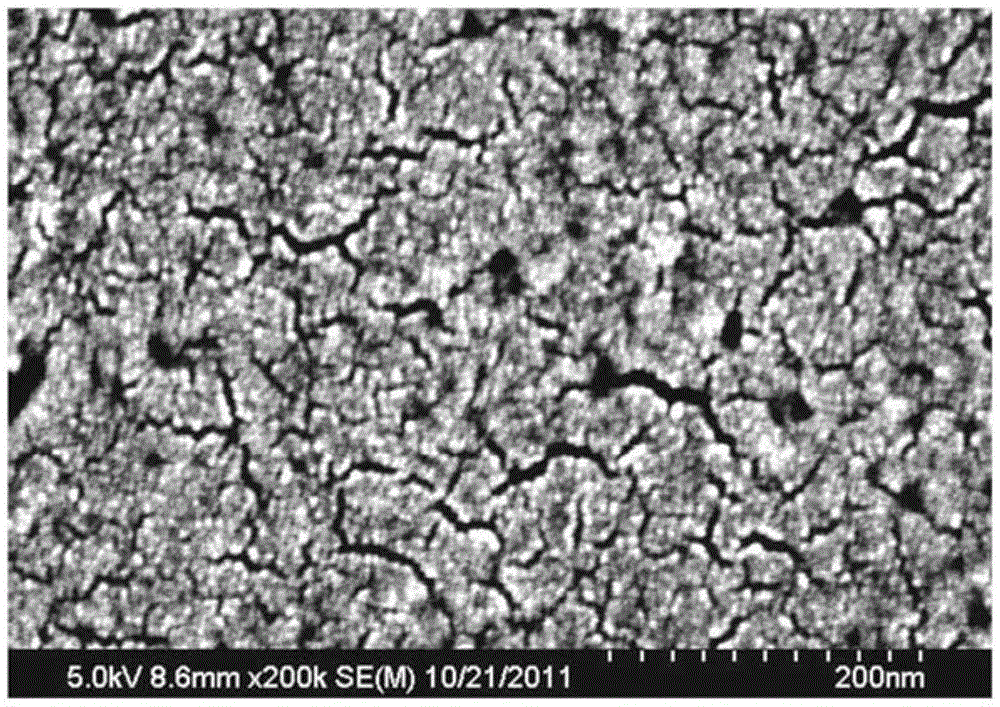

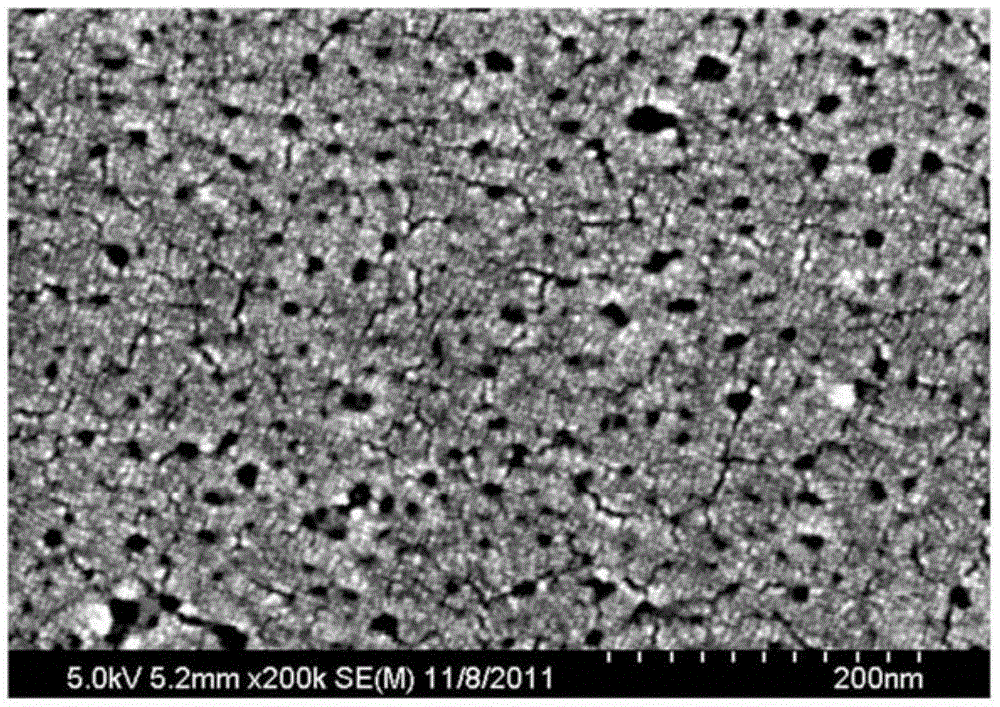

[0055] Here, images of the polysulfone layer surface analyzed by scanning electron microscopy (SEM) are shown in figure 1middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com