Fragile soft capsule and preparation method thereof

A technology for soft capsules and capsule materials, applied in the field of fragile soft capsules and their preparation, can solve the problems of uncontrollable degree of volatilization by heat, influence on smoking feeling, excessive aroma, etc., and achieve good moisturizing function, excellent wettability, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

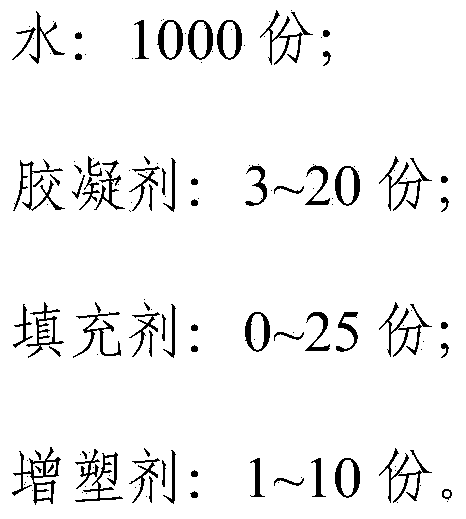

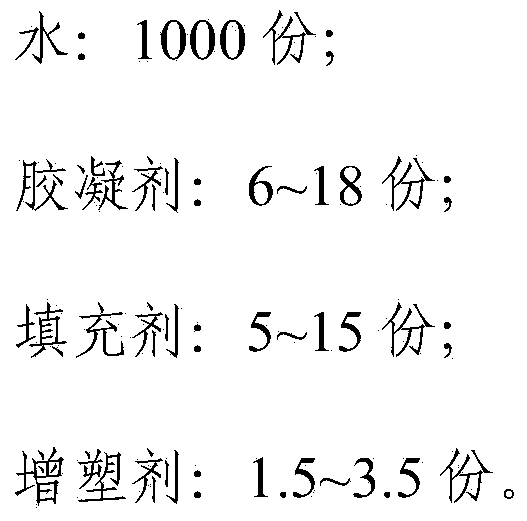

[0032] Embodiment 1: A fragile soft capsule, comprising a core material and a capsule material wrapped outside the core material. The core material is lipophilic food flavor. The raw material formula of the capsule material is water, gelling agent, filler, plasticizer and coloring agent. The weight ratio of each component is: water: 1000kg; gelling agent: 12kg; filler: 12kg; plasticizer: 6kg.

[0033] Wherein, water is deionized water.

[0034] The gelling agent is a mixture of carrageenan and gelatin, and the weight ratio of carrageenan and gelatin is 50:50.

[0035] The bulking agent is dextrin.

[0036] The plasticizer is glycerin.

[0037] The colorant is food coloring.

[0038] The method for preparing above-mentioned frangible soft capsule, comprises the steps:

[0039] 1) Add the water, plasticizer, gelling agent and filler described in the preparation of the above-mentioned capsule material into the glue tank in sequence at 70°C, stir until the materials are full...

Embodiment 2

[0046] Embodiment 2: A fragile soft capsule, comprising a core material and a capsule material wrapped outside the core material. The core material is lipophilic food flavor. The raw material formula of the capsule material is water, gelling agent, plasticizer and coloring agent, and the weight ratio of each component is: water: 1000kg; gelling agent: 3kg; plasticizer: 1kg.

[0047] Wherein, water is deionized water.

[0048] The gelling agent is carrageenan.

[0049] The plasticizer is sorbitol.

[0050] The colorant is food coloring.

[0051] Its production method is basically the same as Example 1, the difference is that the temperature described in step 1 is 60°C; the temperature described in step 3 is 60°C; the temperature described in step 5 is 10°C, the humidity is 15%, and the time is 18°C Hour.

[0052] The final prepared single fragile soft capsule has a total weight of 5 mg, a diameter of 2 mm, and a crushing strength of 0.9N. Wherein, the core material accoun...

Embodiment 3

[0053] Embodiment 3: A fragile soft capsule, comprising a core material and a capsule material wrapped outside the core material. The core material is lipophilic food flavor. The raw material formula of the capsule material is water, gelling agent, filler, plasticizer and colorant, and the weight ratio of each component is: water: 1000kg; gelling agent: 6kg; filler: 5kg; plasticizer: 1.5kg.

[0054] Wherein, water is deionized water.

[0055] The gelling agent is carrageenan and a mixture of gelatin and modified starch. The weight ratio of carrageenan to other gums is 65:35.

[0056] The bulking agent is a mixture of maltodextrin and hydroxypropyl methylcellulose.

[0057] The plasticizer is a mixture of maltitol and triacetin.

[0058] The colorant is food coloring.

[0059] Its production method is basically the same as Example 1, the difference is that the temperature described in step 1 is 70°C; the temperature described in step 3 is 70°C; the temperature described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com