Biological treatment method and device for waste gas produced by printing and dyeing wastewater

A technology for biological treatment, printing and dyeing wastewater, applied in separation methods, chemical instruments and methods, air quality improvement, etc., to achieve the effects of less investment, good treatment effect, and advanced deodorization technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for the biological treatment of exhaust gas produced by printing and dyeing wastewater, comprising the following steps:

[0065] The exhaust gas pretreated in the absorption tower is subjected to two levels of biological treatment: primary biological treatment and secondary biological treatment;

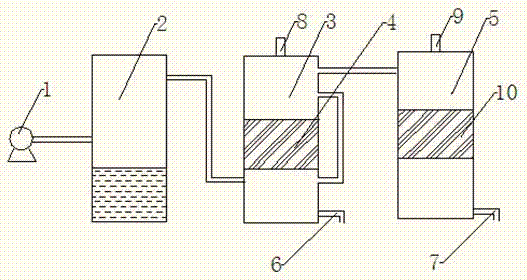

[0066] The steps of the two-stage biological treatment are: pass the waste gas through the biological trickling filter bed 3 for treatment, and then pass it into the biological filter bed 5 for treatment;

[0067] Specific steps are as follows:

[0068] The exhaust gas is passed through the fan 1 into the humidifier 2, and after humidification, the exhaust gas is introduced into the biological trickling filter bed 3 through the pipeline, and is treated by microorganisms on the inner packing layer I4 of the biological filter bed 5; the waste liquid is discharged from the lower part of the biological trickling filter bed 3 The waste liquid outlet I flows out;

[0069]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com