A semi-active magnetic-sensitive rubber automobile engine mount

A technology of automobile engine and magnetic sensitive rubber, which is applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc. It can solve the problems that affect the NVH performance of the car, cannot adjust the stiffness or damping, and limit the wide range of applications, etc., and achieve simple structure , Good vibration reduction effect, and the effect of improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

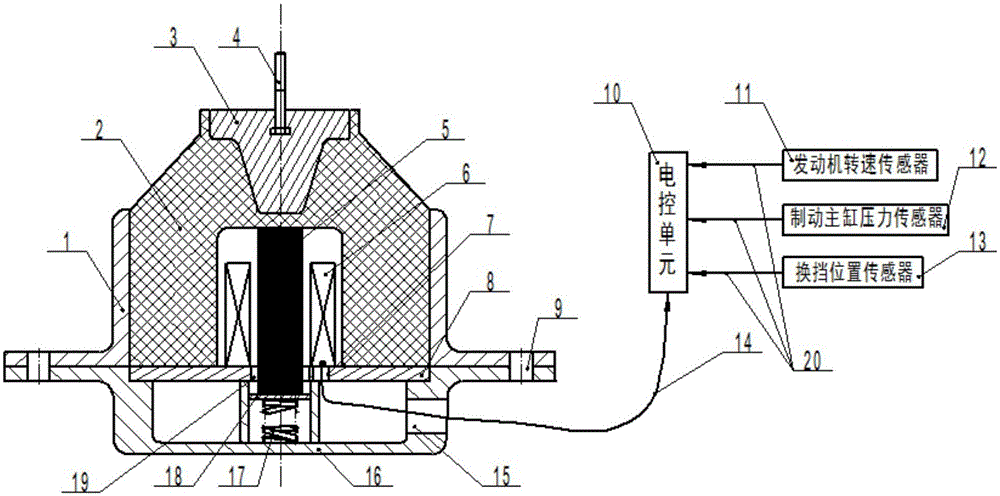

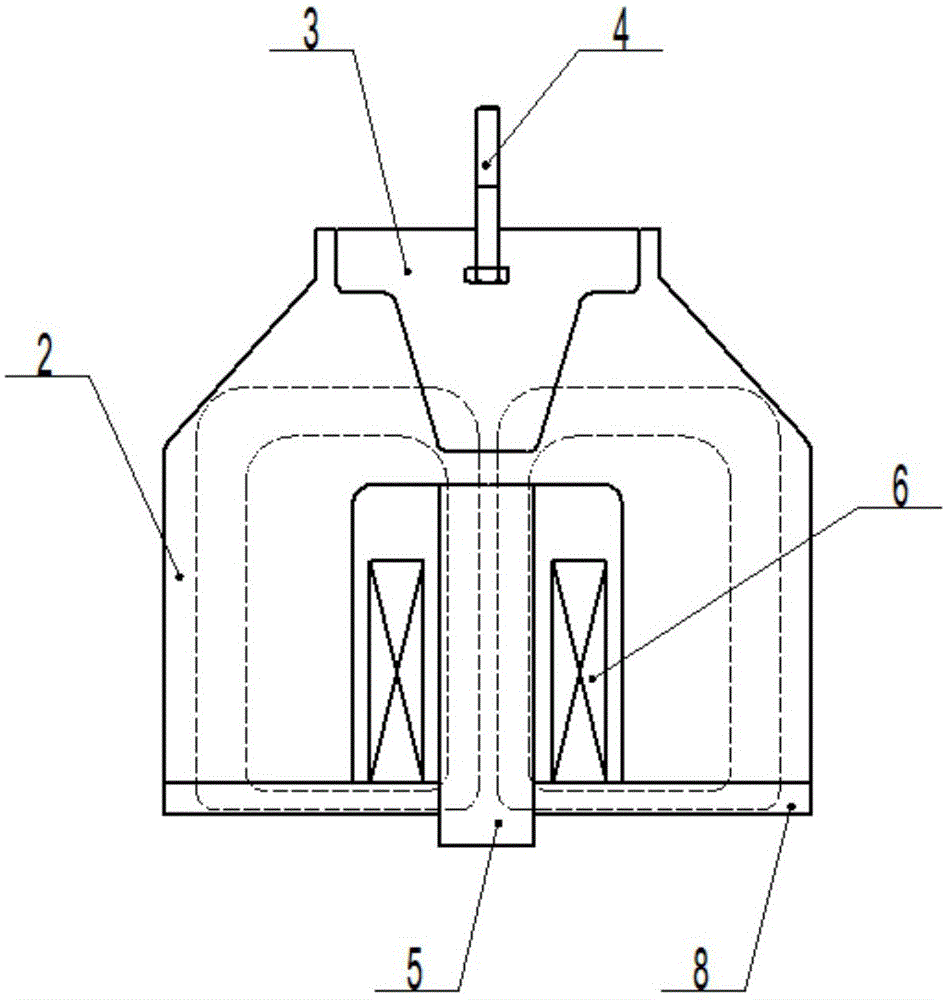

[0031] Such as figure 1 As shown, a magnetic-sensitive rubber semi-active automobile engine mount of the present invention includes the following components: upper casing 1, magnetic-sensitive rubber main spring 2, magnetic-sensitive rubber plug 3, center bolt 4, excitation core 5, excitation Coil 6, threading hole 7, platform 8, connecting hole 9, electronic control unit 10, engine speed sensor 11, brake master cylinder pressure sensor 12, shift position sensor 13, control line 14, cooling hole 15, lower casing 16, Coil spring 17, support disc 18, iron core movement hole 19 and signal line 20. The position connection relationship between them is: the central bolt 4 is preset in the magnetic-sensitive rubber block 3, and the magnetic-sensitive rubber block 3 and the magnetic-sensitive rubber main spring 2 are vulcanized and fixed together; the magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com