Nano tio2 sol coating method, tool and generated coating on ceramic glaze

A ceramic glaze and nano-technology, which is applied in the field of coating nano-TiO2 sol on the surface of ceramic glaze, can solve the problems of difficult control of coating thickness and high temperature resistance, and achieve high energy consumption, no high cost, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0035] Nano-TiO 2 The method that sol is coated on ceramic glaze, comprises the following steps:

[0036] Step 1: pickling of ceramic glaze; preparation of nano-TiO 2 sol, and thicken it;

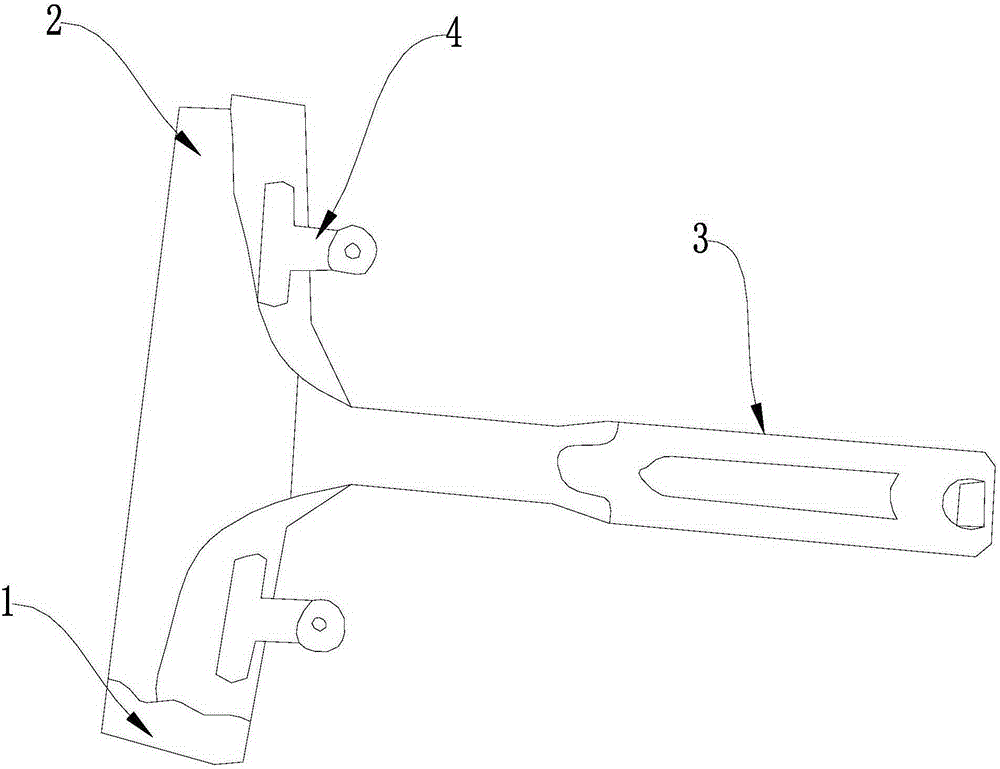

[0037] Step 2: Nano TiO 2 The sol is coated on the ceramic glaze; the coating tool includes a glass water scraper and a dust-free cloth; the length of the glass water scraper is 10cm-60cm; the dust-free cloth is one to six layers, and is flatly wrapped on the glass Squeegee on;

[0038] Step 3: Nano TiO 2 The sol was naturally air-dried and solidified into nano-TiO 2 film, and then heat-treat the ceramic glaze.

[0039] Further, the nano-TiO 2The preparation method of the sol is: adding an anionic surfactant or a nonionic surfactant with a mass percentage of 0.1%-10% to the nano-TiO with a mass percentage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com