Manufacturing method of low free chlorine gold salt

A manufacturing method and low ionization technology, applied in the direction of gold organic compounds, etc., can solve the problems of difficult mass production, poor gold plating characteristics, etc., and achieve the effects of less localized corrosion, improved risk, and good solder wetting characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Dissolve half of 100.0g of potassium aurous cyanide in 500ml of 12.5% citrate solution, and adjust the liquid temperature to 80°C while stirring, then add half of 46.1g of tripotassium citrate and 15.0g of lemon Half of the acid was stirred to dissolve.

[0040] Then, a small amount of 90 ml of 30% hydrogen peroxide was slowly added to this solution while bubbling carbon monoxide. While confirming the reaction status, add the remaining potassium aurous cyanide, tripotassium citrate, and citric acid. While keeping carbon monoxide bubbling and continuing, the temperature of the reaction solution was kept at 50° C., and the pH value was kept at 5.6-6.0, while aging for three hours.

[0041] Furthermore, the remaining hydrogen peroxide was slowly added to the reaction solution. After adding the hydrogen peroxide, the temperature of the reaction solution was kept at 80°C, and the pH value was kept at 5.6-6.0, so that the carbon monoxide bubbles continued for five hours, ...

Embodiment 2

[0046] Dissolve about half of 50.0 g of potassium aurous cyanide in 300 ml of 10% citrate solution, adjust the liquid temperature to 80°C while stirring, then add half of 23.0 g of tripotassium citrate, citric acid 7.5 g half, stirring to dissolve.

[0047] Then, in the solution, carbon monoxide and ozone gas generated by the ozone generating device were started to bubble. While confirming the reaction status, the remaining potassium aurous cyanide, tripotassium citrate, and citric acid were added. While making the bubbling of carbon monoxide and ozone gas continue, the temperature of the reaction solution was kept at 50° C., and the pH value was kept at 5.6-6.0, while aging for eighteen hours.

[0048] Furthermore, the temperature of the reaction solution was kept at 80°C, and the pH value was kept at 5.6-6.0, so that the carbon monoxide and ozone gas bubbles were kept for five hours, so that the reaction solution was concentrated.

[0049] The concentrated reaction solutio...

reference example 1

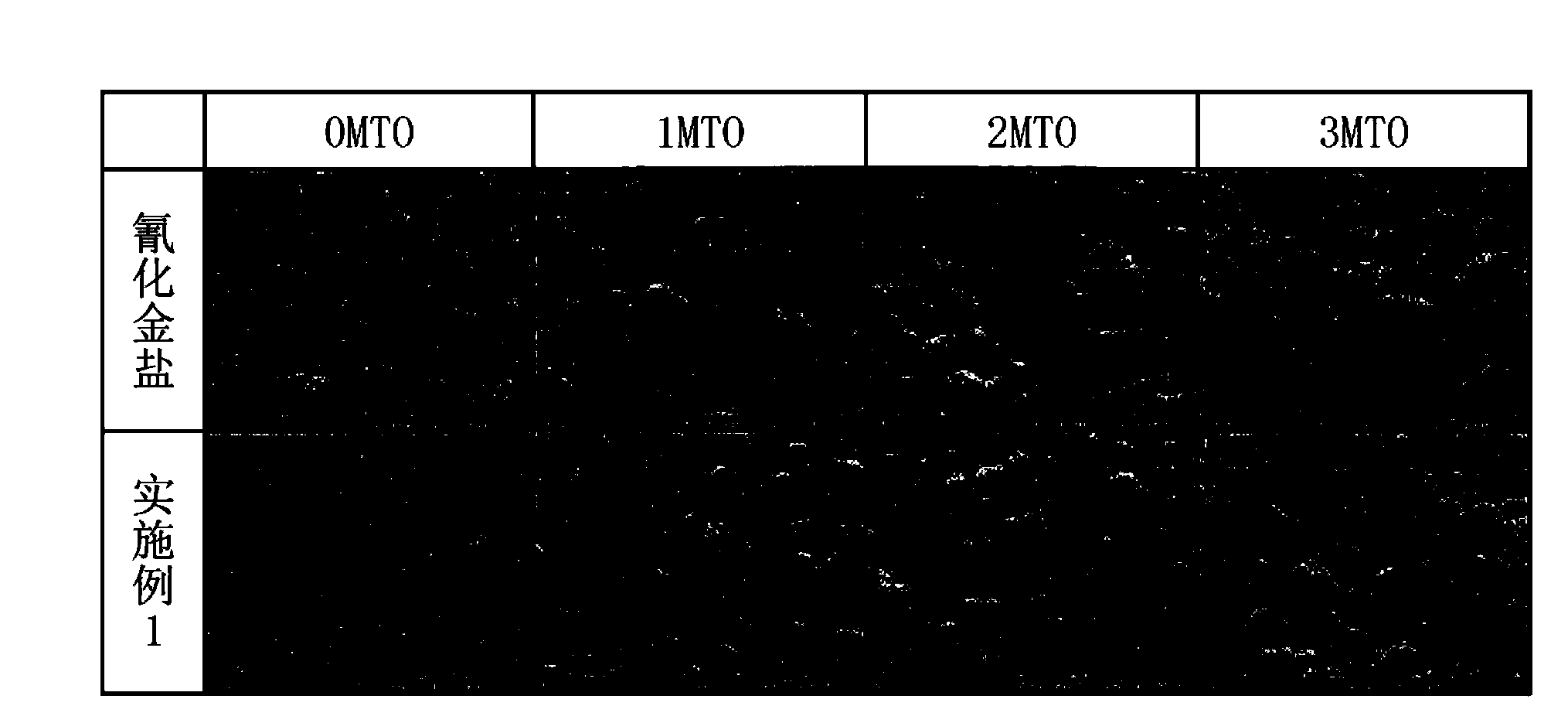

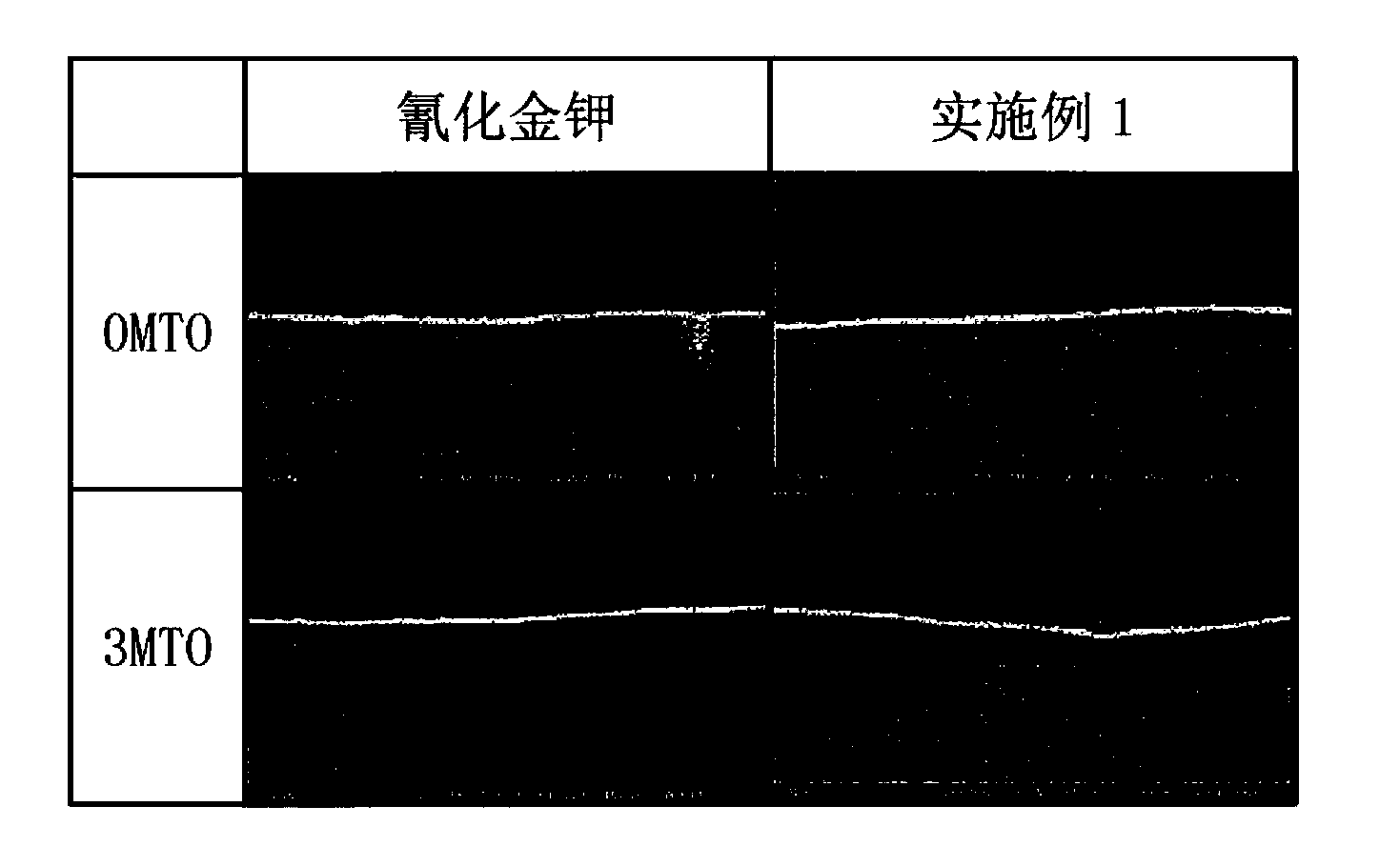

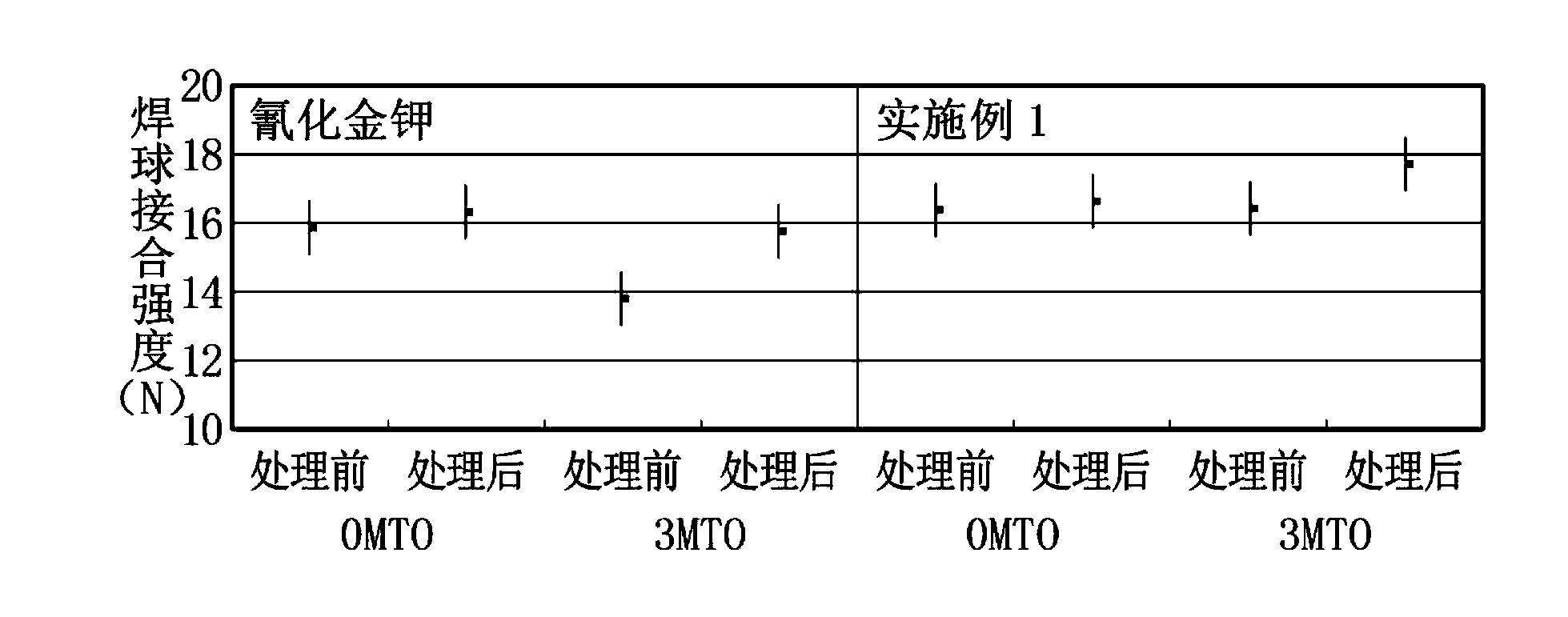

[0059] Acidic degreasing was performed on the displacement type electroless gold plating test substrate using a commercially available electroless gold plating process (manufactured by Uemura Kogyo Co., Ltd.) etching acid soak endow palladium catalyst After electroless nickel plating, use the low free cyanide gold salt replacement gold electroplating solution obtained in Example 1 to form an electroless gold (about 0.05 μm) / nickel film (about 5 μm) on the copper electrode.

[0060] Displacement-type electroless gold plating is to add 1.8L of pure water to a beaker, mix 0.2L of commercially available displacement-type electroless gold plating chemicals (trade name: TKK-51 product of Uemura Industrial Co., Ltd.), and then add to Example 1 The obtained low free cyanogen gold salt is used to build a displacement type electroless gold electroplating solution. The basic operating conditions of the gold electroplating solution are that the gold concentration is set at 1.0 g / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com