Preparation method of acrylonitrile-butadiene rubber

A technology of nitrile-butadiene rubber and nitrile-butadiene rubber is applied in the field of preparation of nitrile-butadiene rubber, which can solve the problems of poor oil resistance and physical and mechanical properties, and achieve the effects of excellent physical and mechanical properties, good oil resistance and excellent physical and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

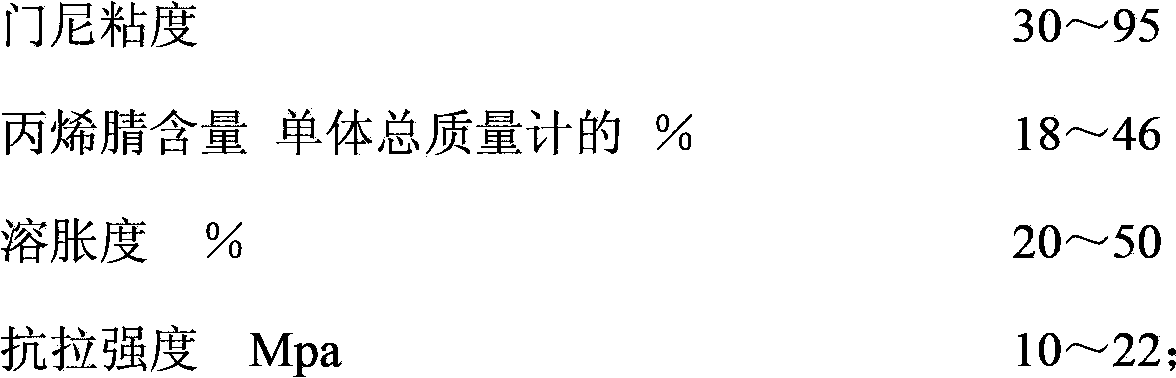

[0061] The preparation method of acrylonitrile-butadiene rubber of the present invention is obtained through cold batch emulsion polymerization by raw material butadiene and acrylonitrile, and it is characterized in that prepared acrylonitrile-butadiene rubber reaches the following technical indicators:

[0062]

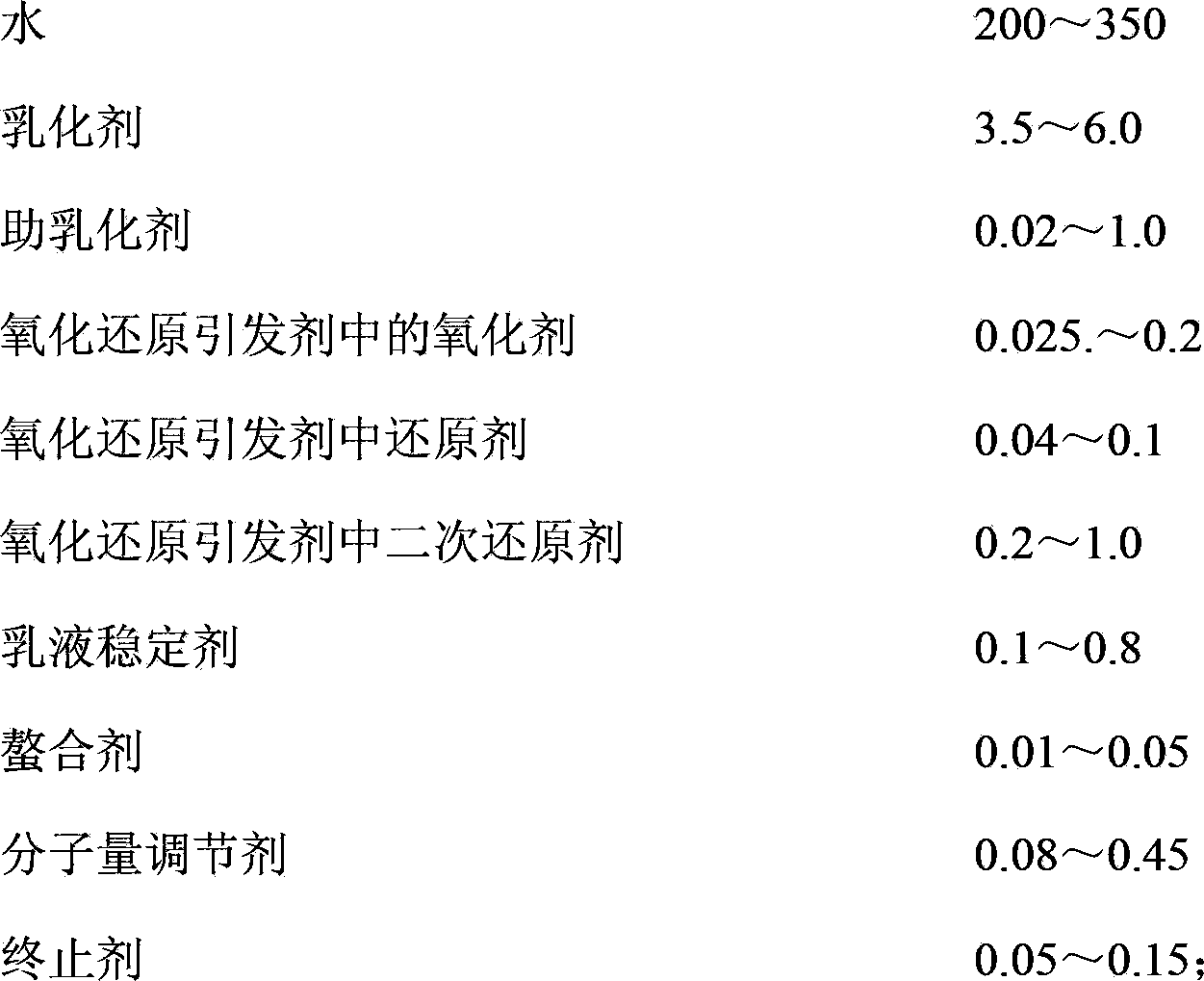

[0063] Adopt the following raw material proportioning according to mass parts:

[0064]

[0065] Its preparation method comprises the following steps:

[0066] Sequentially add water, emulsifier, co-emulsifier, emulsion stabilizer and part of monomer acrylonitrile in the formula to the polymerization kettle, and pass nitrogen gas to test the pressure. After confirming that there is no leakage in the polymerization kettle, replace it with nitrogen several times, and then add copolymerization Monomer butadiene: Start the stirring of the polymerization tank, and pass cold water into the interlayer of the polymerization tank and the cooling coil to cool down. Second...

Embodiment 2~ Embodiment 8

[0068] According to the method and step of embodiment 1, formula and performance are listed in table 1

[0069] Table 1

[0070]

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com