Chain-extended modified PLA/PETG (polylactic acid/poly (ethylene terephthalateco-1, 4-cylclohexylenedimethylene terephthalate)) blend and preparation method thereof

A technology of ethylene glycol phthalate and cyclohexanedimethanol ester, which is applied in the field of polymer material blending and modification, can solve the problems of large viscosity difference, difficult PLA performance, poor compatibility, etc., and achieve an increase in toughness , low cost, good modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) First, the PLA and MDI, which were pre-dried in an oven at 60°C for 36 hours, were composed according to the mass ratio, and granulated by twin-screw melt extrusion at a processing temperature of 180°C and a speed of 60r / min;

[0032] (2) Dry the pellets in step (1) in an oven at 60°C for 36 hours to obtain PLA pellets after chain extension;

[0033] (3) The chain-extended PLA pellets in step (2) and PETG are composed according to the mass ratio, and the same processing conditions as described in step (1) are used to melt and blend through a twin-screw extruder to obtain chain-extended modification The polylactic acid / polyethylene terephthalate-1,4-cyclohexanedimethanol blend prepared by the method, the mass ratio of PLA:PETG:MDI is controlled to be 80:20:5;

[0034] (4) Dry the blend in step (3) and mold it into an injection molded product by an injection molding machine. The properties of the product are shown in Table 1.

Embodiment 2

[0036] (1) First, the PLA and MDI, which were pre-dried in an oven at 60°C for 36 hours, were composed according to the mass ratio, and granulated by twin-screw melt extrusion at a processing temperature of 180°C and a speed of 60r / min;

[0037] (2) Dry the pellets in step (1) in an oven at 60°C for 36 hours to obtain PLA pellets after chain extension;

[0038] (3) The chain-extended PLA pellets in step (2) and PETG are composed according to the mass ratio, and the same processing conditions as described in step (1) are used to melt and blend through a twin-screw extruder to obtain chain-extended modification The polylactic acid / polyethylene terephthalate-1,4-cyclohexanedimethanol blend prepared by the method, the control PLA:PETG:MDI mass ratio is 80:20:3;

[0039] (4) Dry the blend in step (3) and mold it into an injection molded product by an injection molding machine. The properties of the product are shown in Table 1.

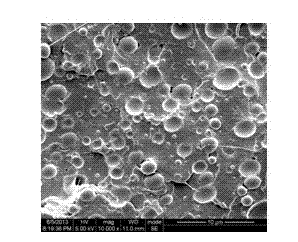

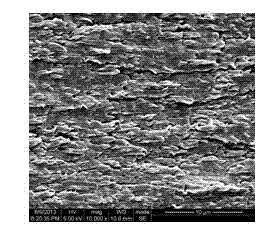

[0040] (5) Do a scanning electron microscope (SEM) ...

Embodiment 3

[0046] (1) First, the PLA and MDI, which were pre-dried in an oven at 60°C for 36 hours, were composed according to the mass ratio, and granulated by twin-screw melt extrusion at a processing temperature of 180°C and a speed of 60r / min;

[0047] (2) Dry the pellets in step (1) in an oven at 60°C for 36 hours to obtain PLA pellets after chain extension;

[0048] (3) The chain-extended PLA pellets in step (2) and PETG are composed according to the mass ratio, and the same processing conditions as described in step (1) are used to melt and blend through a twin-screw extruder to obtain chain-extended modification The polylactic acid / polyethylene terephthalate-1,4-cyclohexanedimethanol blend prepared by the method, the PLA:PETG:MDI mass ratio is controlled to be 90:10:3;

[0049] (4) Dry the blend in step (3) and mold it into an injection molded product by an injection molding machine. The properties of the product are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com