Preparation method of protective paint for expressway guardrail

A technology of highway and protective paint, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of difficult user acceptance, high production cost, long transportation cycle, etc., and achieve the effect of excellent comprehensive performance and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

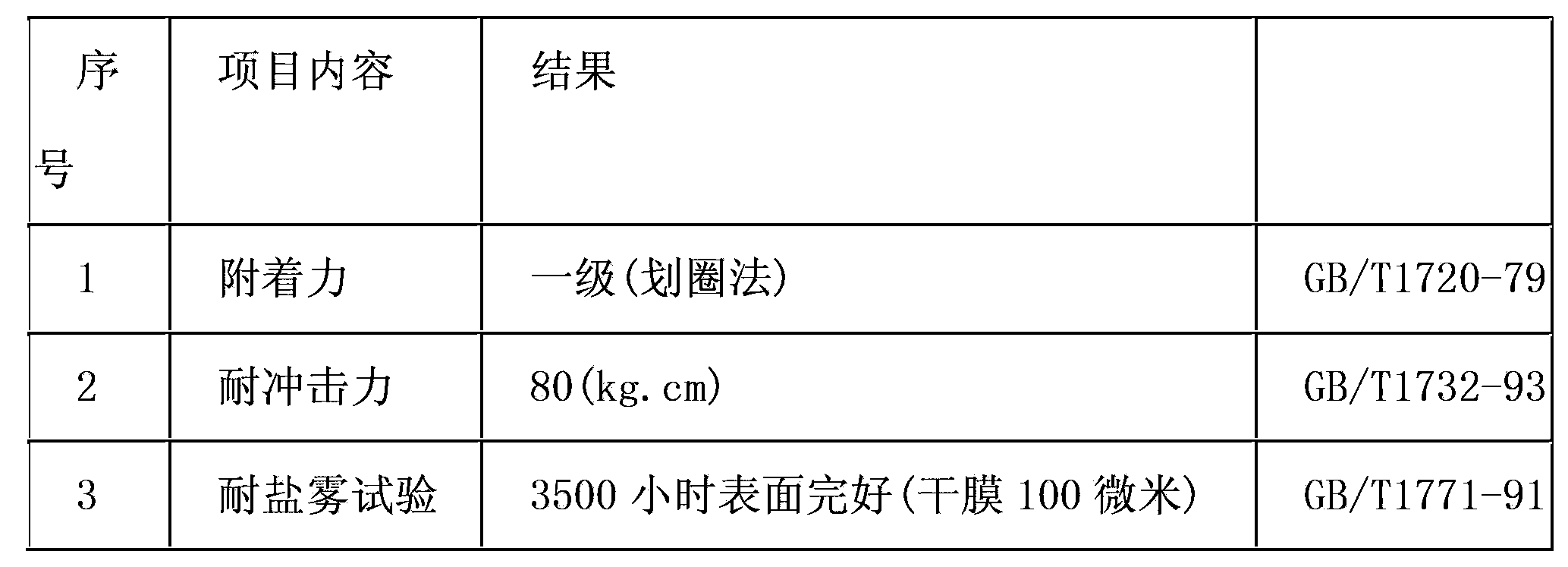

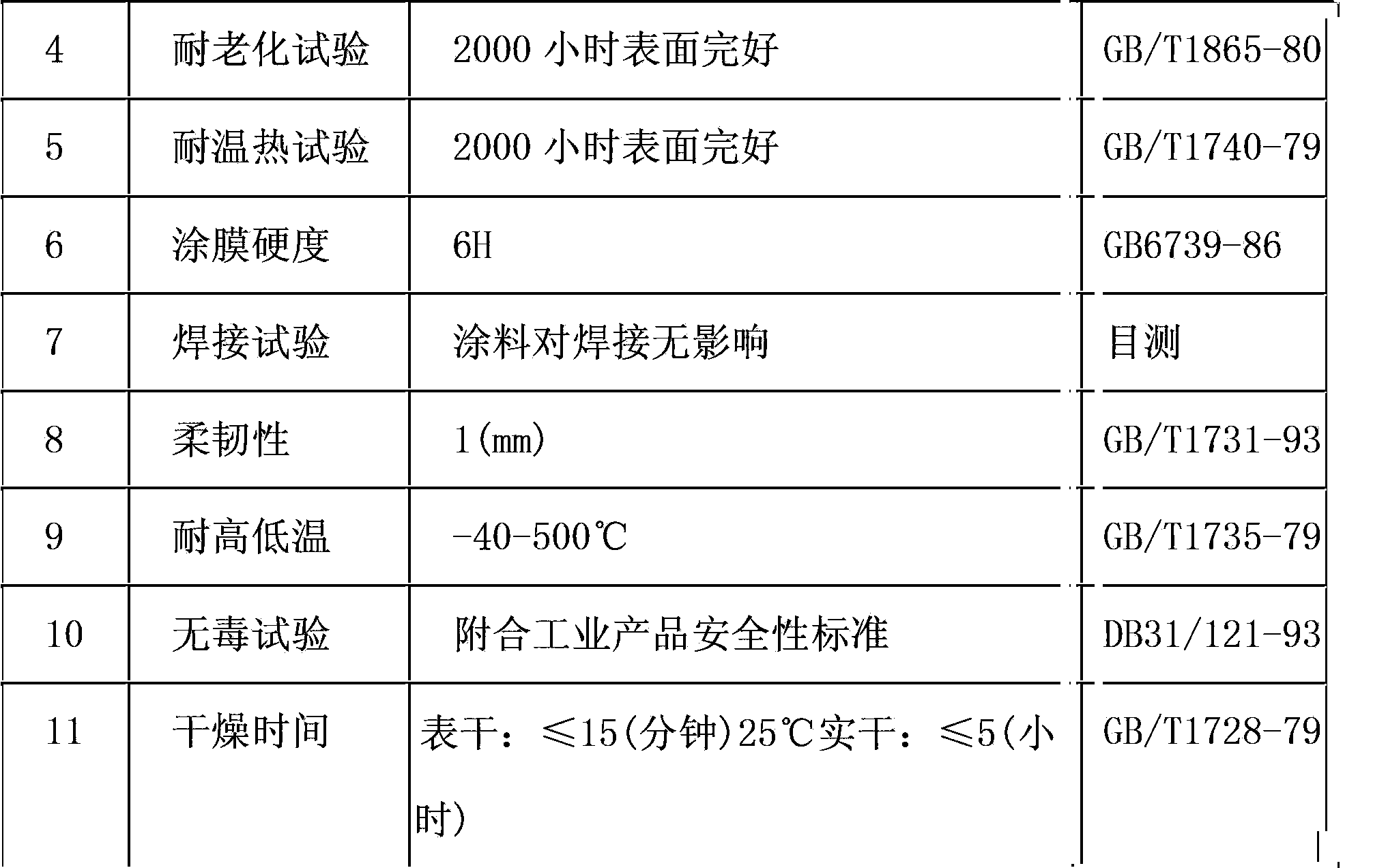

Image

Examples

Embodiment 1

[0017] A preparation method for a protective paint for highway guardrails, the protective paint is composed of the following components in parts by weight: 100 parts of polyvinyl acetate, 70 parts of polyvinyl alcohol methyl ester, 40 parts of polyvinyl alcohol, 2- 13 parts of chloroethanesulfonic acid, 5 parts of dimethyl phthalate, 8 parts of methanol, 20 parts of titanium dioxide, 14 parts of purified bentonite, 63 parts of BYK306, and 70 parts of water. The preparation method includes the following steps: Ester, polyvinyl alcohol methyl ester, and polyvinyl alcohol are added to a reaction kettle filled with water, the temperature is raised and stirring is started, so that the rotation speed is 100 rpm, and 2-chloroethanesulfonic acid is added dropwise at 120°C. React at low temperature for 60 minutes; add methanol into the reaction kettle and react at 160°C for 120 minutes; then add BYK306, titanium dioxide and purified bentonite and stir evenly, then cool down to room temp...

Embodiment 2

[0019] A preparation method for a protective paint for highway guardrails, the protective paint consists of the following components in parts by weight: 110 parts of polyvinyl acetate, 60 parts of polyvinyl alcohol methyl ester, 50 parts of polyvinyl alcohol, 2- 11 parts of chloroethanesulfonic acid, 8 parts of dimethyl phthalate, 6 parts of methanol, 30 parts of titanium dioxide, 12 parts of purified bentonite, 65 parts of BYK3065 parts, and 60 parts of water. The preparation method includes the following steps: Ester, polyvinyl alcohol methyl ester, and polyvinyl alcohol are added to a reaction kettle filled with water, the temperature is raised and stirring is started, so that the rotation speed is 200 rpm, and 2-chloroethanesulfonic acid is added dropwise at 100°C. React at low temperature for 90 minutes; add methanol into the reaction kettle and react at 130°C for 150 minutes; then add BYK306, titanium dioxide and purified bentonite and stir evenly, then cool down to room ...

Embodiment 3

[0021] A preparation method for a protective paint for highway guardrails, the protective paint consists of the following components in parts by weight: 105 parts of polyvinyl acetate, 65 parts of polyvinyl alcohol methyl ester, 45 parts of polyvinyl alcohol, 2- 12 parts of chloroethanesulfonic acid, 6.5 parts of dimethyl phthalate, 7 parts of methanol, 25 parts of titanium dioxide, 13 parts of purified bentonite, 64 parts of BYK3064 parts, and 65 parts of water. The preparation method includes the following steps: Ester, polyvinyl alcohol methyl ester, and polyvinyl alcohol are added to a reaction kettle filled with water, the temperature is raised and stirring is started, so that the rotation speed is 150 rpm, and 2-chloroethanesulfonic acid is added dropwise at 110°C. React at low temperature for 75 minutes; add methanol into the reaction kettle and react at 140°C for 135 minutes; then add BYK306, titanium dioxide and purified bentonite and stir evenly, then cool down to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com