Self-repair conductive adhesive and preparation method thereof

A conductive adhesive and self-repair technology, applied in the field of conductive adhesive, can solve the problems of volume shrinkage, stress concentration, and affecting the strength repair rate of cracks, etc., to achieve the effect of improving strength, repairing conductive network, and good repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

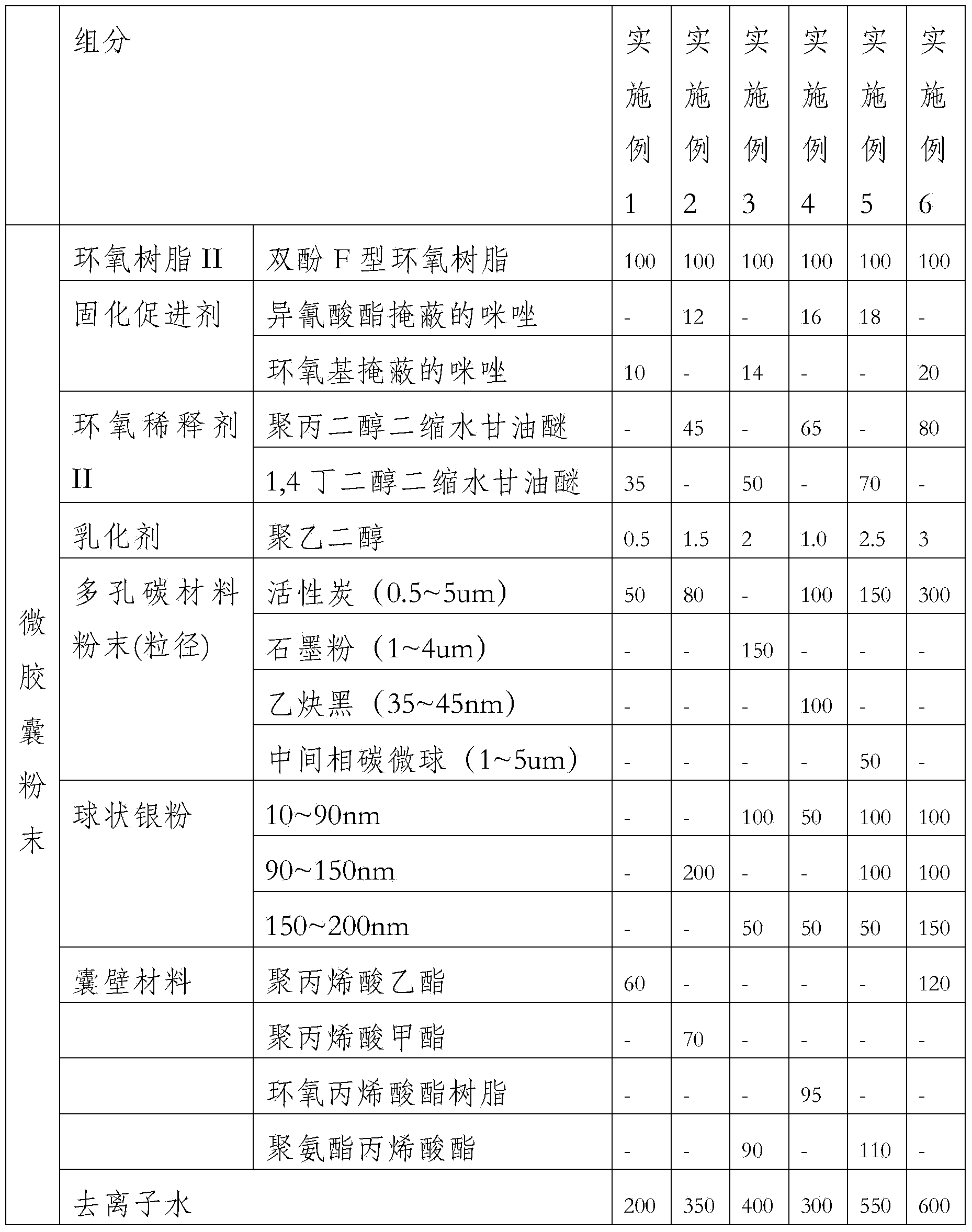

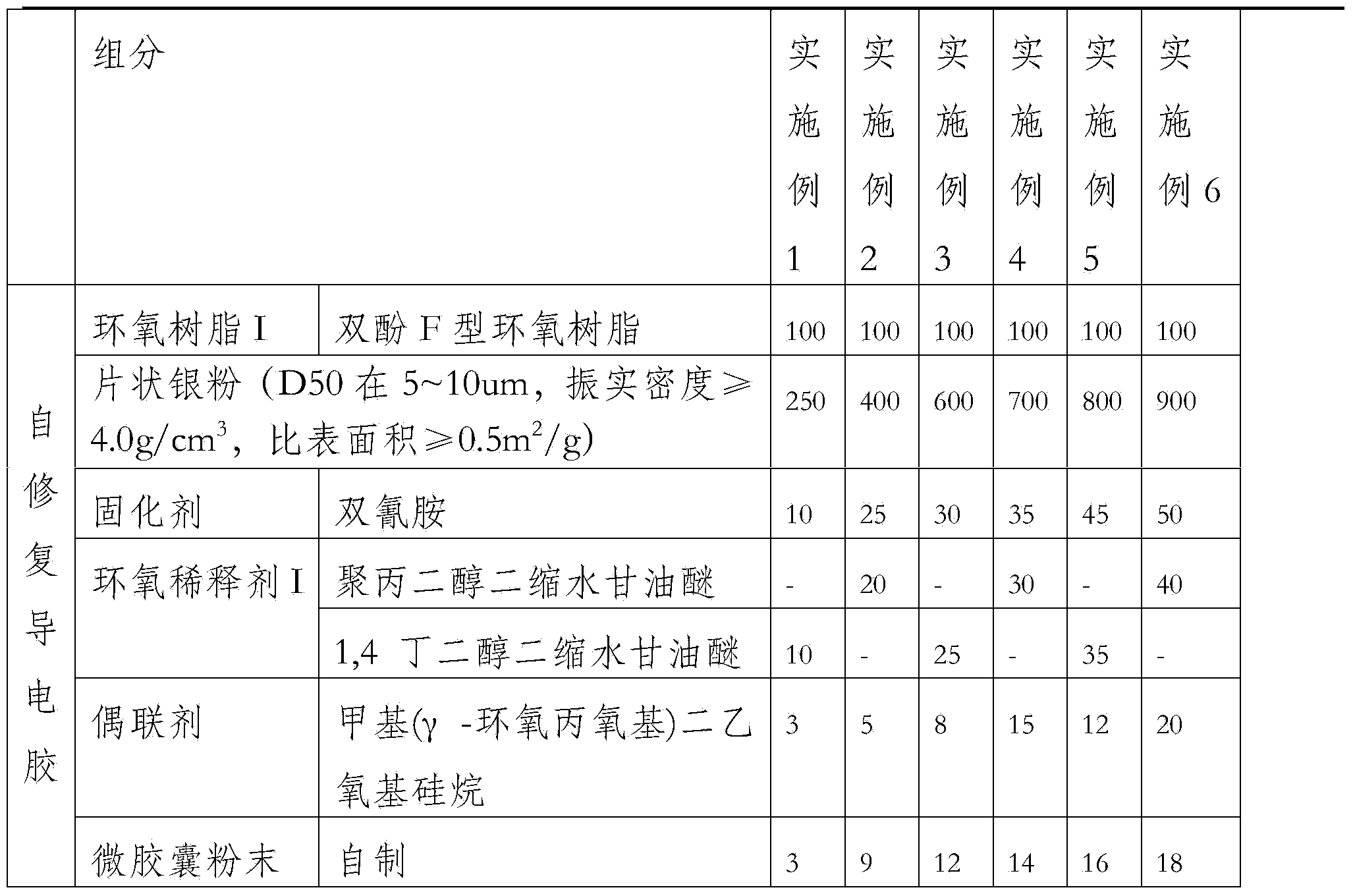

[0035] Weigh epoxy diluent II, epoxy resin II, curing accelerator, emulsifier, deionized water and porous carbon material powder required for preparing microcapsule powder according to the mass given in Table 1, mix it, and grind , to form a uniform epoxy resin-porous carbon material powder emulsion; then heat the obtained epoxy resin-porous carbon material powder emulsion in a constant temperature water bath to 50-85°C and stir evenly, and then add the corresponding parts according to Table 1 The pre-polymerization solution of the capsule wall material is stirred evenly, and the deionized water is removed by centrifugal separation and vacuum drying to obtain microcapsule powder. Next, weigh microcapsule powder, epoxy diluent I, epoxy resin I, curing agent, flake silver powder, coupling agent according to the number of parts given in Table 2, and mix evenly at room temperature to obtain self-healing conductive adhesive .

Embodiment 4~6

[0037] According to the mass weighing given in Table 1, epoxy diluent II, epoxy resin II, curing accelerator, emulsifier, deionized water, spherical silver powder and porous carbon material powder required for preparing microcapsule powder are mixed, and grind to form a uniform epoxy resin-porous carbon material powder emulsion; then heat the obtained epoxy resin-porous carbon material powder emulsion in a constant temperature water bath to 50-85°C and stir evenly, and then add A corresponding amount of pre-polymerization liquid of capsule wall material is stirred evenly, and deionized water is removed through centrifugal separation and vacuum drying to obtain microcapsule powder. Next, weigh the microcapsule powder, epoxy diluent I, epoxy resin II, curing agent, flake silver powder, and coupling agent according to the parts given in Table 2, and mix them uniformly at room temperature to obtain a self-healing conductive adhesive .

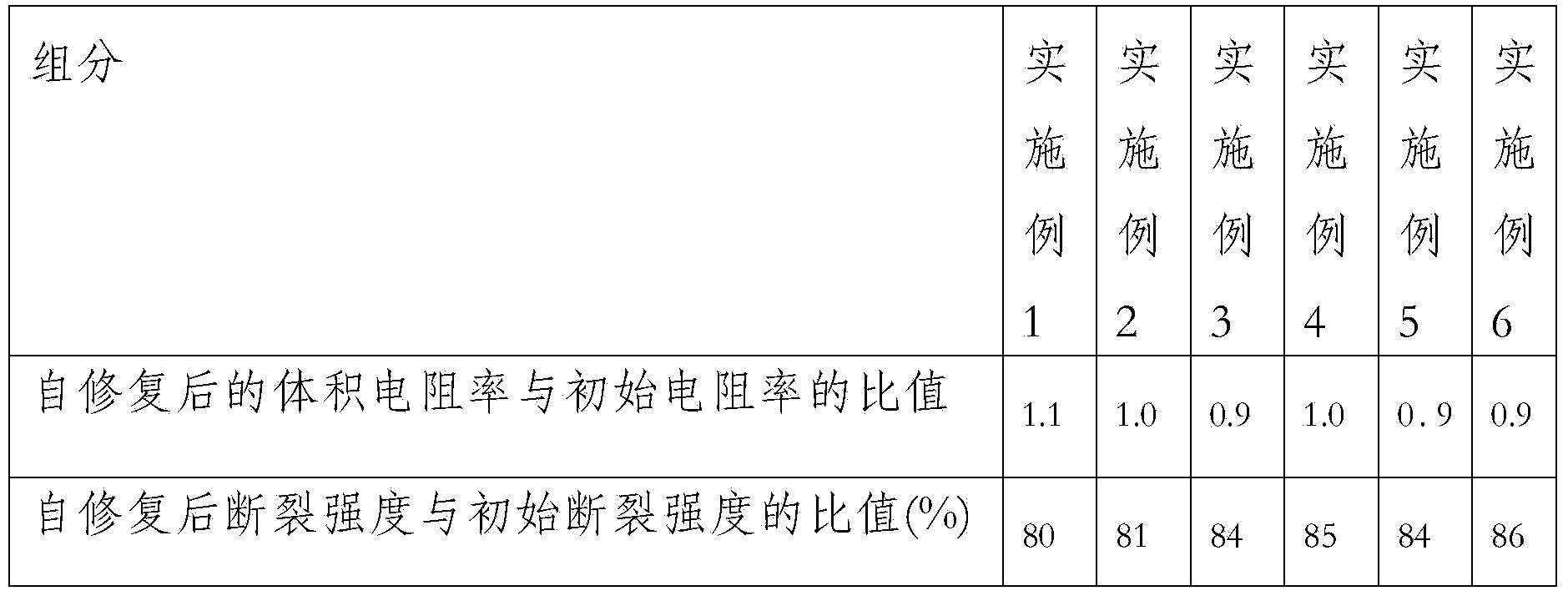

[0038] The self-healing conductive adhesive...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap