Preparation method for methanol gasoline with good stability

A methanol gasoline and stability technology, applied in the field of synthetic fuels, can solve problems such as precipitation and poor stability of methanol gasoline, and achieve the effect of good combustion performance and no change in properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

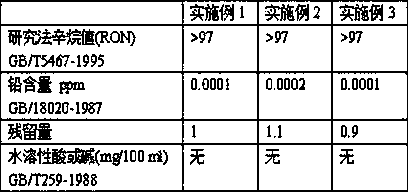

Examples

Embodiment 1

[0022] A kind of preparation method of methanol gasoline with good stability comprises the steps:

[0023] In the first step, heavy benzene 3Kg, alkyl naphthalene 2Kg, amyl nitrate 1Kg, sodium dihydrogen phosphate 1Kg, ethylene-vinyl acetate copolymer 4Kg, light diesel oil 15Kg, tert-butyl peroxyacetate 1Kg, No. 70 gasoline 5Kg, Put 2Kg of dispersant and 1Kg of metal deactivator into the reactor, stir at 30°C for 4 hours to obtain the mixture;

[0024] In the second step, add 60Kg of methanol to the mixture, lower the temperature to 20°C, continue to stir for 2 hours, and let it stand for 10 hours.

[0025] The dispersant is succinimide. The metal deactivator is adipic acid dihydrazide.

[0026]

Embodiment 2

[0028] A kind of preparation method of methanol gasoline with good stability comprises the steps:

[0029] In the first step, heavy benzene 5Kg, alkylnaphthalene 4Kg, amyl nitrate 3Kg, sodium dihydrogen phosphate 3Kg, ethylene-vinyl acetate copolymer 6Kg, light diesel oil 20Kg, tert-butyl peroxyacetate 3Kg, No. 70 gasoline 10Kg, Put 3Kg of dispersant and 3Kg of metal deactivator into the reactor, and stir at 40°C for 6 hours to obtain the mixture;

[0030] In the second step, add 80Kg of methanol to the mixture, lower the temperature to 25°C, continue to stir for 3 hours, and let it stand for 12 hours.

[0031] The dispersant is succinimide. The metal deactivator is adipic acid dihydrazide.

[0032]

Embodiment 3

[0034] A kind of preparation method of methanol gasoline with good stability comprises the steps:

[0035] In the first step, 4Kg of heavy benzene, 3Kg of alkylnaphthalene, 2Kg of amyl nitrate, 2Kg of sodium dihydrogen phosphate, 5Kg of ethylene-vinyl acetate copolymer, 17Kg of light diesel oil, 2Kg of tert-butyl peroxyacetate, 7Kg of No. 70 gasoline, Put 2Kg of dispersant and 2Kg of metal deactivator into the reactor, stir at 35°C for 5 hours to obtain the mixture;

[0036] In the second step, add 70Kg of methanol to the mixture, lower the temperature to 22°C, continue to stir for 2 hours, and let it stand for 11 hours.

[0037] The dispersant is succinimide. The metal deactivator is adipic acid dihydrazide.

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com