Methanol gasoline stabilizer

A technology of methanol gasoline and stabilizer is applied in the field of additives for methanol gasoline and additives for improving the stability of methanol gasoline, which can solve the problems of unfavorable environmental protection and health, increase the emission of toxic substances in tail gas, etc., and improve the resistance to phase separation when encountering water. , the effect of excellent pollutant discharge and improved water capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] According to mass percentage 2-octylamine 18.0%, N-tert-butylpiperazine 19.0%, 4-N-butoxybenzonitrile 19.0%, allyl phenoxyacetate 16.0%, 1,3-acetone dicarboxylic acid Add 14.5% diethyl ester and 13.5% 3-dimethylaminoanisole into a stirring tank, and stir evenly at room temperature to obtain a transparent and clear methanol-gasoline stabilizer product.

[0019] Add 0.4% stabilizer to methanol, mix evenly, and use BMT-180 ultrasonic instrument of BRANSON in the United States for 20 minutes at room temperature, then add other additives and gasoline to obtain methanol gasoline.

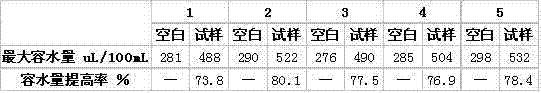

[0020] Five commercially available national standard gasolines were selected as base oils, and 5 methanol gasoline samples were prepared as blank groups. According to the method of this embodiment, 5 experimental samples of methanol gasoline containing stabilizer were prepared, and the water resistance test was carried out.

[0021] The test method refers to the local standards of Shanxi Province ...

Embodiment 2

[0025] According to mass percentage 2-octylamine 18.0%, N-tert-butylpiperazine 15.0%, 4-N-butoxybenzonitrile 20.0%, allyl phenoxyacetate 17.5%, 1,3-acetone dicarboxylic acid Add 15.0% diethyl ester and 14.5% 3-dimethylaminoanisole into a stirring tank, and stir evenly at room temperature to obtain a transparent and clear methanol-gasoline stabilizer product.

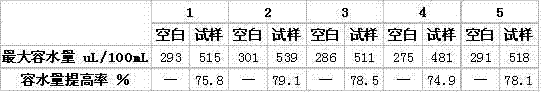

[0026] Test method is the same as embodiment 1. The experimental results are shown in Table 2.

[0027] Table 2 Maximum water capacity test results.

[0028]

Embodiment 3

[0030] According to mass percentage 2-octylamine 25.0%, N-tert-butylpiperazine 16.0%, 4-N-butoxybenzonitrile 15.0%, allyl phenoxyacetate 16.0%, 1,3-acetone dicarboxylic acid Add 12.0% diethyl ester and 16.0% 3-dimethylaminoanisole into a stirring tank, and stir evenly at room temperature to obtain a transparent and clear methanol-gasoline stabilizer product.

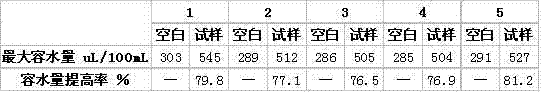

[0031] Test method is the same as embodiment 1. The experimental results are shown in Table 3.

[0032] Table 3 Maximum water capacity test results.

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com