Preparation method of epoxy modified castor oil

A technology of epoxy modification and castor oil, which is applied in the direction of fatty acid production, fatty acid esterification, fatty acid chemical modification, etc. It can solve the problems of low epoxy value, complicated preparation process and high preparation cost of modified castor oil, and achieve color and luster Stability, simple synthetic route, high epoxy value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

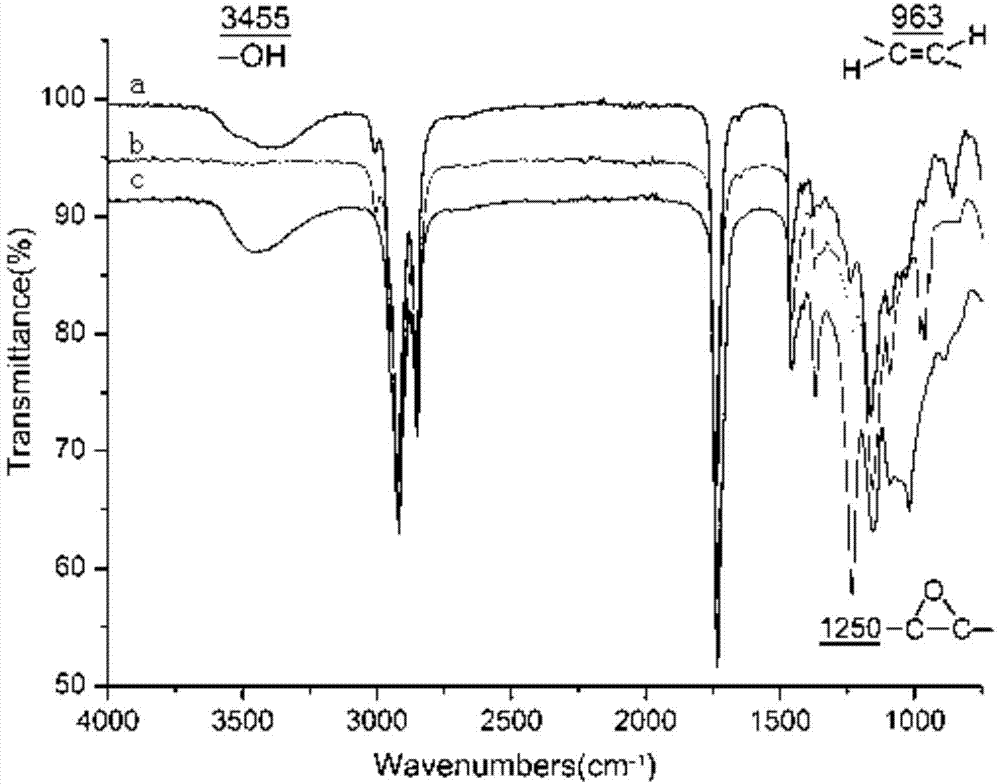

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of epoxy-modified castor oil comprises the steps: A, add castor oil 100.0g in the 250mL flask that is equipped with thermometer, stirrer, distillation head, SiO 2 -Al 2 o 3 3.5g of solid acid catalyst, heated to 230°C for dehydration treatment under the condition of vacuum degree of 1mm Hg, reacted for 2.5h; B, then cooled down to 45°C, and started to add 46.0g of peracetic acid dropwise for 1.5h , Carry out epoxidation reaction at 55°C for 3.0h after the dropwise addition; At ℃, the vacuum distillation was stopped to obtain epoxy-modified castor oil.

[0024] The epoxy value of the product is 6.1%, the iodine value is 3.1g iodine / 100g oil, and the color iron-cobalt colorimetry is 1#.

Embodiment 2

[0026] Add 100.0 g of castor oil and 1.6 g of Amberlyst15 solid acid catalyst to a 250 mL flask equipped with a thermometer, agitator, and a distillation head, and heat to 220° C. for dehydration treatment under a vacuum of 8 mm Hg, and react for 3.0 h; Then lower the temperature to 40°C, and start to add 25.0g of hydrogen peroxide dropwise for 1.5h. After the dropwise addition, carry out the epoxidation reaction at 55°C for 4.0h; , Carry out underpressure distillation under 60 ℃, when distillation outlet temperature drops to 40 ℃, stop underpressure distillation, make epoxy dehydration castor oil.

[0027] The epoxy value of the product is 6.3%, the iodine value is 3.2g iodine / 100g oil, and the color iron-cobalt colorimetry is 1#.

Embodiment 3

[0029] Add 100.0g of castor oil and 2.6g of B2O3-Al2O3 solid acid catalyst into a 250mL flask equipped with a thermometer, agitator, and a distillation head, and heat to 240°C for dehydration treatment under a vacuum of 2 mm Hg. The reaction is 1.5 h. Then the temperature was lowered to 40° C., and 85.0 g of peracetic acid was added dropwise for 2.0 hours. After the dropwise addition, the epoxidation reaction was carried out at 55° C. for 3.0 hours. After the reaction was finished, the particulate matter was filtered off, and vacuum distillation was carried out at a vacuum of 2 mm Hg at 50° C. When the distillation outlet temperature dropped to 40° C., the vacuum distillation was stopped to obtain epoxy dehydrated castor oil.

[0030] The epoxy value of the product is 6.8%, the iodine value is 3.0g iodine / 100g oil, and the iron-cobalt colorimetry is 1-2#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com