A kind of soap particle and preparation method thereof and laundry soap prepared therefrom

A technology of laundry soap and soap particles, which is applied in the manufacture of soap solutions, chemical instruments and methods, soap detergent compositions, etc., can solve the problems of affecting detergency, poor solubility, yellowing, etc., to improve stability, The effect of slowing down the decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] (Soap noodles and their preparation process, the following percentages are mass percentages)

[0088] Raw material composition and mass percentage:

[0089] Fatty acid 60.27%

[0090] Alkali: 9.52%

[0091] MES: 4.42%,

[0092] Water: 25.0%,

[0093] Sodium chloride: 0.35%,

[0094] Glycerin: 0.35%,

[0095] EDTA-4Na: 0.044%,

[0096] HEDP-4Na: 0.044%

example 1

[0097] Fatty acid (C12 and C14 mixture) and fatty acid (C16 and C18 mixture) ratio 1:4

[0098] Process steps of soap nugget preparation:

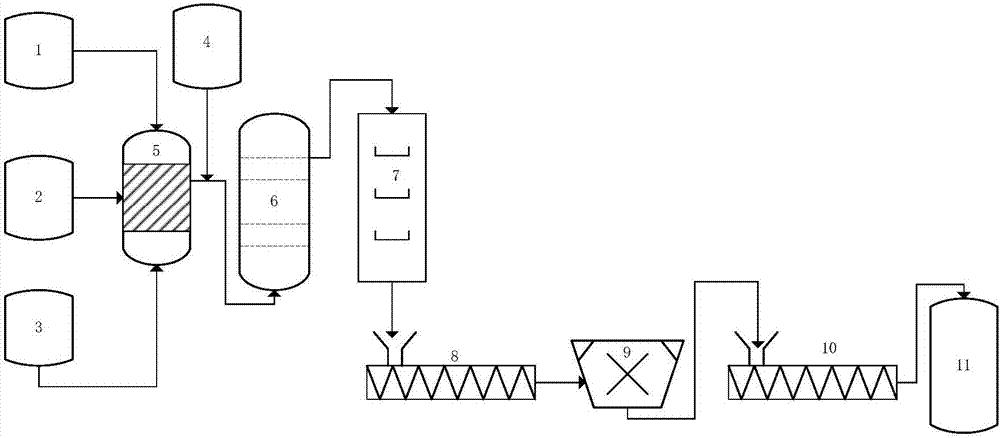

[0099] As attached figure 1 It shows that after pre-dissolving sodium chloride, EDTA-4Na, HEDP-4Na, and glycerin in water, they are configured as salt water into the storage tank, and fatty acid (C12 and C14 mixture), fatty acid (C16 and C18 mixture), liquid caustic soda , Glycerin, MES, water, sodium chloride and EDTA-4Na in solution, HEDP-4Na is pumped in through a flow pump, mixed by a mixer, and then enters a vacuum spray dryer for drying and molding, and then extruded through a refiner to produce soap grain. The soap nuggets are prepared into soap nuggets through a soap forming line.

[0100] The soap nuggets are as follows:

[0101] Water: 6.1%

[0102] Fatty acid salt 88%

[0103] MES: 5%

[0104] Glycerin: 0.4%

[0105] Sodium chloride: 0.4%

[0106] EDTA-4Na: 0.05%

[0107] HEDP-4Na: 0.05%

Embodiment 2

[0109] (Soap noodles and their preparation process, the following percentages are mass percentages)

[0110] Raw material composition and mass percentage:

[0111] Fatty acid: 56.72%;

[0112] Alkali: 8.94%

[0113] MES: 8.85%

[0114] Water: 24.7%

[0115] Sodium chloride: 0.35%

[0116] Glycerin: 0.35%

[0117] EDTA-4Na: 0.044%

[0118] HEDP-4Na: 0.044%

[0119] Fatty acid (C12 and C14 mixture) and fatty acid (C16 and C18 mixture) are 1:4

[0120] Process steps of soap nugget preparation:

[0121] As attached figure 1 It shows that after pre-dissolving sodium chloride, EDTA-4Na, HEDP-4Na, and glycerin in water, they are configured as salt water into the storage tank, and fatty acid (C12 and C14 mixture), fatty acid (C16 and C18 mixture), liquid caustic soda , Glycerin, MES, water, sodium chloride and EDTA-4Na in solution, HEDP-4Na is pumped in through a flow pump, mixed by a mixer, and then enters a vacuum spray dryer for drying and molding, and then extruded through a refiner to produce so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com