Method and device for producing biodiesel according to coal-based methanol and palm oil supercritical method

A biodiesel, palm oil technology, applied in the direction of biofuel, fatty acid esterification, etc., can solve the problem that biodiesel has not been reported in the literature, and achieve the effect of less corrosiveness of equipment and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

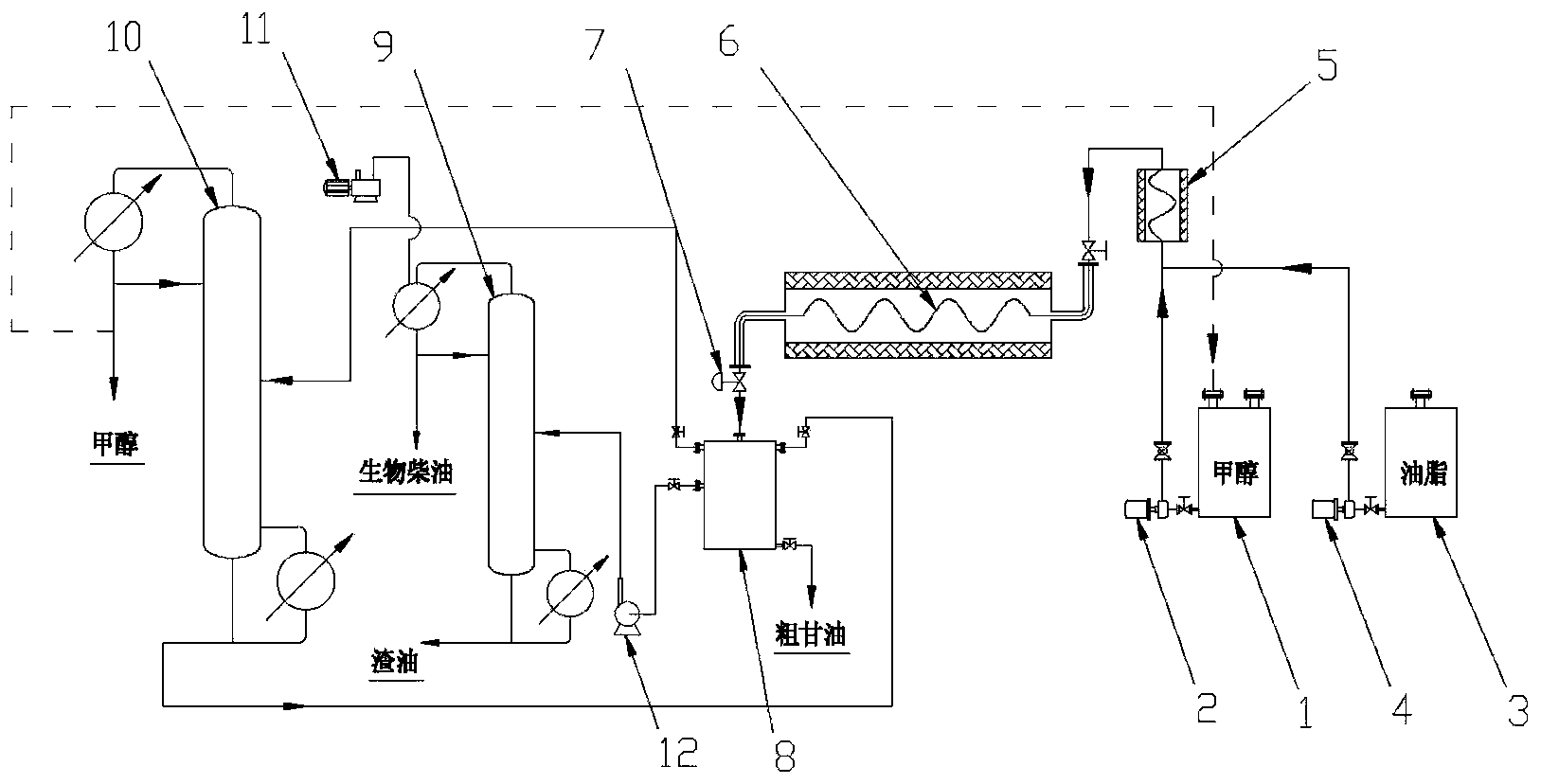

[0034] Using plunger pumps 2 and 4, according to the coal-based methanol:palm oil ratio of 40:1, the coal-based methanol in the methanol storage tank 1 and the palm oil in the oil storage tank 3 are continuously fed into the Φ20×1000mm preheater respectively 5. After mixing and preheating to a temperature of 350°C, enter the tubular reactor 6 with a Φ20×5000mm spiral tube, so that the coal-based methanol can undergo transesterification of oil under a supercritical state to produce crude biodiesel and glycerin. Control the temperature of the tubular reactor 6 at 350° C. and the pressure at 20 MPa by automatically controlling the power input of the electric heating, and adjust the residence time of the reactants in the tubular reactor 6 by controlling the opening of the outlet pressure reducing valve 7. 5 minutes. After decompression, the reaction product enters the Φ300×600mm gas-liquid separator 8 and is divided into gas phase (crude methanol) and two liquid phases (the upper ...

Embodiment 2

[0036] Using plunger pumps 2 and 4, according to the coal-based methanol:palm oil leg ratio of 30:1, respectively, the coal-based methanol in the methanol storage tank 1 and the palm oil leg in the oil storage tank 3 are continuously fed into the Φ20×1000mm pre- Heater 5, after mixing and preheating to a temperature of 300°C, enters into tubular reactor 6 with a Φ20×5000mm spiral tube, so that methanol can perform transesterification reaction of oil under supercritical state to generate biodiesel and glycerin. By automatically controlling the power input of the electric heating, the temperature of the tubular reactor 6 is controlled at 300°C and the pressure is at 15MPa, and the residence time of the reactants in the tubular reactor 6 is adjusted by controlling the opening of the outlet pressure reducing valve 7 for 15 minutes. After decompression, the reaction product enters the Φ300×600mm gas-liquid separator 8 and is divided into gas phase (crude methanol) and two liquid ph...

Embodiment 3

[0038] Use plunger pumps 2 and 4 to continuously feed the coal-based methanol in methanol storage tank 1 and the palm oil in oil storage tank 3 into the Φ20×1000mm pre-heater according to the ratio of coal-based methanol:palm oil leg is 35:1. The heater 5, after mixing and preheating to a temperature of 320°C, enters the tubular reactor 6 with a spiral tube of Φ20×5000 mm, so that the methanol can undergo transesterification of oil under supercritical conditions to generate biodiesel and glycerin. By automatically controlling the power input of the electric heating, the temperature of the tubular reactor 6 is controlled at 300°C and the pressure is at 17MPa, and the residence time of the reactants in the tubular reactor 6 is adjusted by controlling the opening of the outlet pressure reducing valve 7 for 10 minutes. After decompression, the reaction product enters the Φ300×600mm gas-liquid separator 8 and is divided into gas phase (crude methanol) and two liquid phases (the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com