A method for preparing nanostructured tungsten carbide composite bulk material by using high temperature and ultra-high pressure

A technology of nano-tungsten carbide and nano-structure, which is applied in the field of cermet materials, and achieves the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

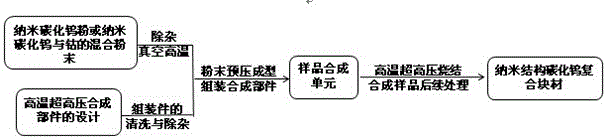

[0023] The mixed powder of tungsten carbide with an average particle size of 30 nm and metal cobalt with an average particle size of 0-2μm is selected, and the mass fraction of tungsten carbide is 85%. figure 1 The process flow chart shown prepares a high-performance nanostructured tungsten carbide composite bulk material.

[0024] The mixed powder of tungsten carbide and cobalt is first subjected to continuous washing, powder-liquid separation washing, heating and drying to remove impurities. Then, the fine powder of the raw material after the removal of impurities is put into the pre-designed mold, and the mold is put into the processing cavity of the vacuum hot pressing furnace. Ensure that the vacuum degree is better than 4 x 10 during processing -3 Pa, temperature is 500-700℃, treatment time is 1-3 hours. The raw materials are pre-compressed with a pressure of about 30 MPa, and the raw materials are immediately sealed after the vacuum high-temperature pre-compression.

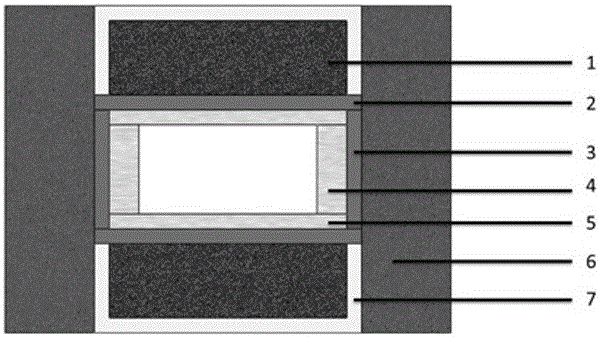

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com