Environment-friendly inter-process antirust liquid

An inter-process anti-rust and environment-friendly technology, applied in the field of anti-rust liquid, to achieve the effect of economical and reasonable discoloration prevention, good discoloration and anti-corrosion protection, and economical and reasonable anti-corrosion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

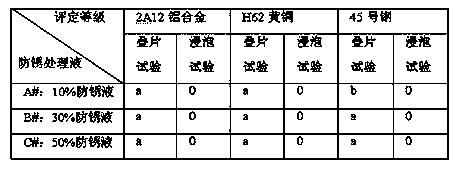

Image

Examples

Embodiment 1

[0028] 1. Preparation of antirust solution

[0029] 1) Preparation of basic components:

[0030] Add 6g of chitosan and 0.15g of polyethylene glycol into 60mL of deionized water to prepare the basic components;

[0031] 2) Preparation of standard antirust solution:

[0032] I. Add 4.5g of phytic acid and 7g of triethanolamine into 200mL of deionized water, then add the basic components prepared in step 1) into the resulting solution, and add deionized water to 1L;

[0033] II. Use 1 mol / L potassium hydroxide deionized aqueous solution to adjust the pH value of the antirust solution to 7.5 before use.

[0034] 2. Pretreatment of samples

[0035] The materials used in the test process include: 2A12 aluminum alloy, H62 brass and 45# carbon steel, which are processed according to the following steps for later use.

[0036] The treatment process for 2A12 aluminum alloy is: degreasing→water washing→removing clad aluminum→water washing→lighting→water washing→drying. Wherein the...

Embodiment 2

[0063] 1. Preparation of antirust solution

[0064] 1) Preparation of basic components:

[0065] Add 2g of chitosan and 0.015g of polyethylene glycol into 60ml of deionized water to prepare the basic components;

[0066] 2) Preparation of standard antirust solution:

[0067] I. Add 1.5g of phytic acid and 1g of triethanolamine to 200ml of deionized water, then add the basic components prepared in step 1) into the resulting solution, and add deionized water to 1L;

[0068] II. Use 1 mol / L potassium hydroxide deionized aqueous solution to adjust the pH value of the antirust solution to 7.5 before use.

[0069] 2. Sample pretreatment

[0070] The materials used in the test process include: 2A12 aluminum alloy, H62 brass and No. 45 steel, which are prepared according to the following steps.

[0071] The treatment process for 2A12 aluminum alloy is: degreasing→water washing→removing clad aluminum→water washing→lighting→water washing→drying. Wherein the solution composition ...

Embodiment 3

[0099] 1. Preparation of antirust solution

[0100] 1) Preparation of basic components:

[0101] Add 20g of chitosan and 0.5g of polyethylene glycol into 60ml of deionized water to prepare the basic components;

[0102] 2) Preparation of standard antirust solution:

[0103] I. Add 10.5g of phytic acid and 15g of triethanolamine into 200ml of deionized water, then add the basic components prepared in step 1) into the resulting solution, and add deionized water to 1L;

[0104] II. Use 1 mol / L potassium hydroxide deionized aqueous solution to adjust the pH value of the antirust solution to 7.5 before use.

[0105] 2. Sample pretreatment

[0106] The materials used in the test process include: 2A12 aluminum alloy, H62 brass and No. 45 steel, which are prepared according to the following steps.

[0107] The treatment process for 2A12 aluminum alloy is: degreasing→water washing→removing clad aluminum→water washing→lighting→water washing→drying. Wherein the solution compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com