Processing method for compact Sirofil elastic yarns

A processing method and technology of elastic yarn, applied in the field of yarn processing, can solve the problems of affecting development, free leakage core, low degree of wrapping yarn cohesion, etc., so as to reduce the chance of fiber swimming, improve yarn strength, and shorten spinning. Effects of the yarn process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The fiber raw materials are wool, elastic filament and silkworm filament, and the blending ratios are 71%, 12% and 17% respectively. The fineness of wool is 15.7μm, the dispersion coefficient of fineness is 21.0%, the length is 63.8mm, the dispersion coefficient of length is 40.7%, and the short hair rate below 30mm is 12.8%. When dyeing wool fiber, ice-cooling dye auxiliaries are added for dyeing. Cooling treatment, endowing the fiber with cool characteristics, and then processed into roving a through needle combing, combing, re-combing and other processes. The fineness of silkworm filament b is 20D, and the fineness of elastic filament c is 40D. The processing of stretchy and cool gathered sirofill pearlescent elastic yarn includes the following steps:

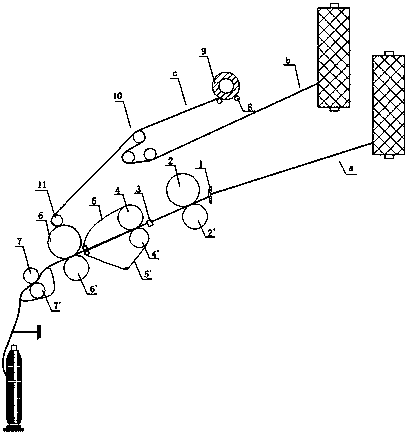

[0025] The elastic filament c is unwound from the elastic filament package 9, and its draft ratio is jointly controlled by the positive feeding roller 8 and the pre-drawing roller 11, and the stretch ratio of the ela...

Embodiment 2

[0028] A processing method of multi-component agglomerated sirofill wool elastic yarn

[0029] The fiber raw materials are wool, T-400 filament and polyester filament, and the blending ratio is 75%, 10%, 15%. The fineness of wool is 18.7μm, the dispersion coefficient of fineness is 20.2%, and the length is 73.8mm. The dispersion coefficient is 45.7%, and the short wool rate below 30mm is 12.0%. The wool fiber is processed into roving a through processes such as dyeing, needle combing, combing, and double combing. The fineness of polyester filament b is 20D, and the fineness of T-400 filament c is 40D. The processing of multi-component gathered sirofill wool elastic yarn comprises the following steps:

[0030] The T-400 filament c is unwound from the elastic filament package 9, and its draft ratio is jointly controlled by the positive feeding roller 8 and the pre-drawing roller 11, and the draft ratio of the T-400 filament c is 2.5 ; Polyester yarn b is unwound from the filam...

Embodiment 3

[0033] A processing method of composite multi-functional agglomerated Sirofill wool elastic yarn

[0034]The fiber raw materials are wool, spandex filament and silver-plated filament, the blending ratio is 70%, 10%, 20%, the fineness of wool is 17.8μm, the dispersion coefficient of fineness is 19.2%, the length is 72.8mm, and the length is discrete The coefficient is 44.7%, and the short wool rate below 30mm is 10.2%. The wool fiber is processed into roving a through dyeing, needle combing, combing, re-combing and other processes. The fineness of silver-plated filament b is 40D, and the fineness of spandex filament c is 20D. The processing of composite multi-functional gathering sirofill wool elastic yarn comprises the following steps:

[0035] Spandex filament c is unwound from elastic filament package bobbin 9, and its draft ratio is jointly controlled by positive feed roller 8 and pre-drawing roller 11, and the draft ratio of spandex filament filament c is 2.0; Silk b is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com