A combustion-to-detonation test device and method

A combustion-to-detonation and testing device technology, which is applied in the direction of chemical analysis by combustion, can solve the problems of tearing of the sample tube and the tripping of the plug, and achieves simple operation, simplified structure, improved test efficiency and reliable data. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

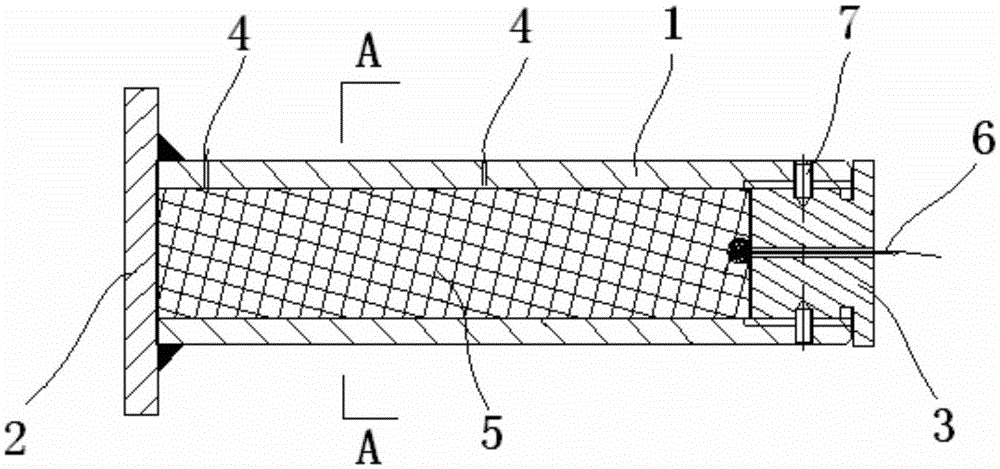

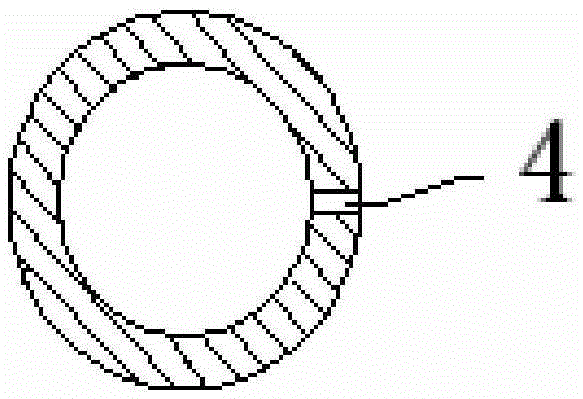

[0032] refer to figure 1 and figure 2 , The combustion-to-blast test device of this embodiment includes a sample tube 1, a verification plate 2 and a plug 3. The size of the sample tube 1 is 40 mm in diameter, 1200 mm in length, and 9 mm in wall thickness. Three testing holes 4 are opened on the wall of the sample tube 1, the axial distance between adjacent testing holes among the three timing holes 4 is 100mm, and the radial angle is 90°. The verification board 2 is welded on the sample tube 1 . The plug 3 is provided with a wire hole for installing the wire 6. The plug 3 and the sample tube 1 are connected by threads and fixed by a drill 4×M8 top wire 7. The thickness of the verification plate 2 is 10mm. The axial distance between the test hole 4 close to the verification board 2 and the verification board 2 is 100 mm.

[0033] During the test, the test sample 5 can be freely filled or cast in the sample tube 1 .

Embodiment 2

[0035] Put 1.64 kg of small propellant pellets prepared by the pellet casting process into the body in four times. Black gunpowder 5g, electric ignition head, tighten the upper plug, connect the ionization probe, time interval recorder, and trigger the detonator synchronously, and the experimenters hide in a safe place to ignite.

[0036] The specific operation process is as follows:

[0037] (1) First, weld the verification plate to the lower end of the sample tube; the plug is connected to the sample tube by an internal thread, and equipped with a drill 4×M8 top wire;

[0038] (2) Put the test sample into the body, leave a space of 40mm from the nozzle, put the black powder bag inserted with the electric ignition head into this space, pass the wire of the electric ignition head through the wire hole of the plug, and then Screw the plug onto the sample tube, and tighten the 4×M8 top wire with drill;

[0039] (3) Insert the ionization probe into the time measuring hole and s...

Embodiment 3

[0044] The sample to be tested in this embodiment is: 0.995 kg of propellant pellets prepared by the screw press process, and the test method is carried out according to the steps in Example 1.

[0045] The results obtained two groups of detonation velocity: 3203m / s and 3148m / s, the average detonation velocity is 3175.5m / s, the standard deviation is 27.5, the detonation velocity is stable; the verification plate has no perforation.

[0046] Utilize the method of national standard to test same sample at the same time, the result is that the sample tube is torn, and the witness plate has no obvious indentation, which is not convenient for judging whether combustion turns to detonation, but with the method of the present invention, because of having a stable detonation velocity, although The detonation velocity is low, but it can still be judged that the transition from combustion to detonation has occurred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com