Sample-injection and transferring device for microporous plate

A technology of transfer device and micro-orifice plate, which is applied in the direction of analyzing materials and instruments, can solve the problems of low work efficiency, easy scattering of reagents and samples, and high production cost, and achieve the effect of simple structure, reduced production cost and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

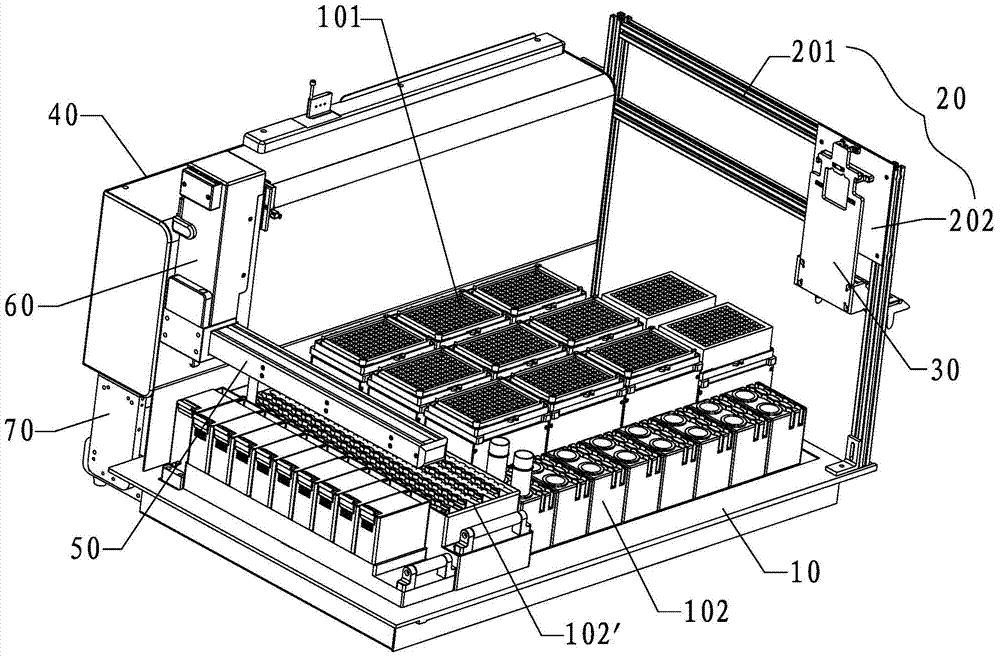

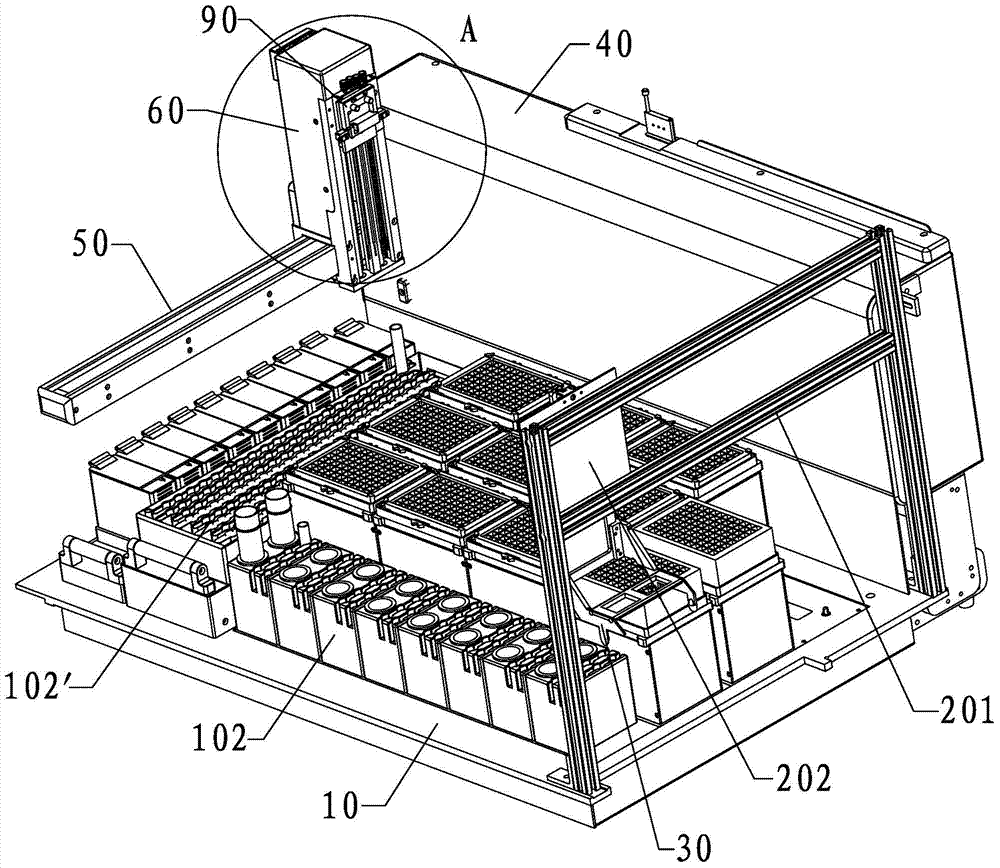

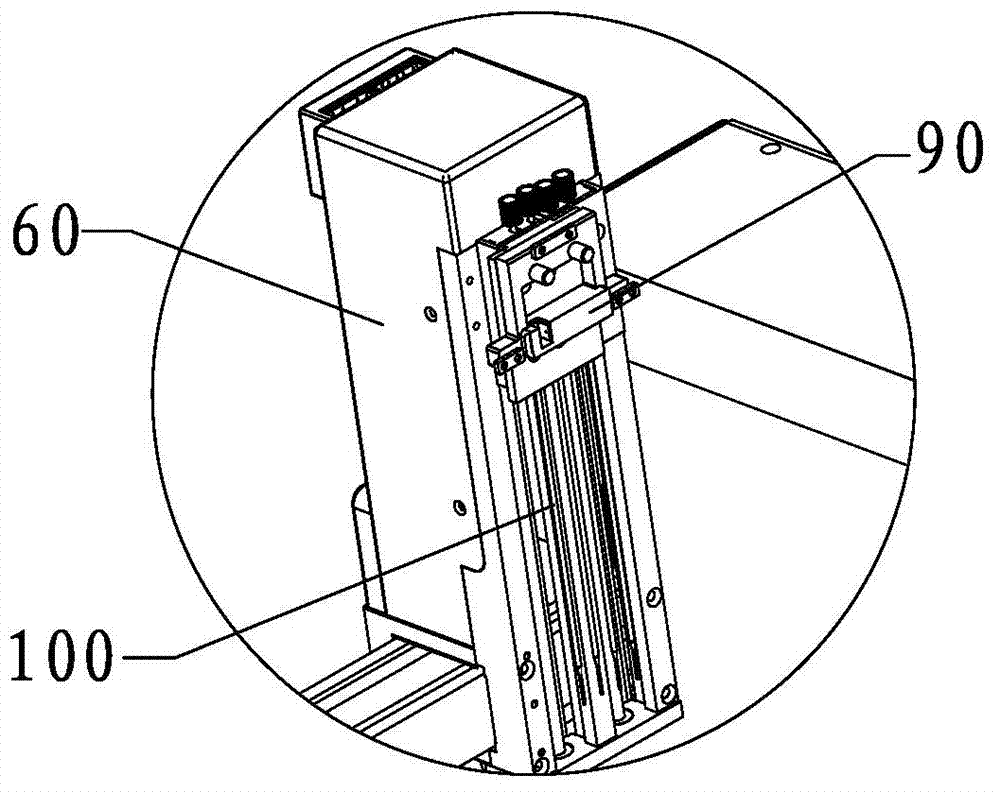

[0037] Such as Figure 1 to Figure 7 As shown, the present invention provides a microplate sampling and transfer device, which includes a workbench 10, a gripper placement mechanism 20, a microplate gripper mechanism 30, a three-axis motion mechanism and a control system, wherein the workbench Sample rack 102, 102' and microporous plate 101 are placed on the 10, various samples or other test solutions are housed in the sample rack 102, 102', the micropore plate 101 has a plurality of holes, and the The samples and / or other test solutions in the sample racks 102, 102' are added to the wells on the microwell plate 101, and then the microwell plate 101 is transferred to the test equipment 80 (enzyme immunoassay analyzer, chemiluminesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com