Optical diffusion film and production process thereof

A technology of light diffusing film and production process, applied in optics, optical components, instruments, etc., can solve the problems such as the qualification rate and production capacity of light diffusing film to be improved, and achieve the effect of avoiding particle sedimentation, excellent anti-stick performance, and avoiding sedimentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

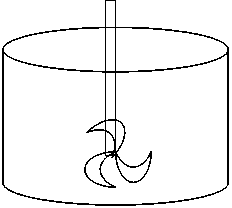

[0039] Add 30 parts by mass of diffusion particles with a particle diameter of 40 microns, 30 parts by mass of resin and 40 parts by mass of solvent into the pneumatic stirring tank, stir and disperse evenly. Then filter the dispersed dispersion liquid into a clean bucket through a 300-mesh filter bag.

[0040] Move the barrel to the side of the coating equipment, add a stirring device on the barrel, and start the stirring device to maintain a slow speed. The stirring speed does not need to be high, it is enough to ensure that the diffusion liquid has a stable rotation effect, so as to avoid the settlement of the diffusion particles due to the long-term standing of the diffusion liquid.

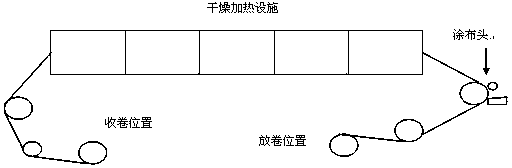

[0041] Spoon the spread from the bucket to the trough and start the machine to start coating. The running speed of the machine is 30 m / min, the setting temperature of the oven is 120 degrees Celsius, and the length of the oven is 20 meters. The diffusion liquid collected from the reflux of ...

Embodiment 2

[0048] Add 20 parts by mass of diffusion particles with a particle diameter of 25 microns, 25 parts by mass of resin and 55 parts by mass of solvent into the pneumatic stirring tank, stir and disperse evenly. Then filter the dispersed dispersion liquid into a clean bucket through a 300-mesh filter bag.

[0049] Move the barrel to the side of the coating equipment, add a stirring device on the barrel, and start the stirring device to maintain a slow speed. The stirring speed does not need to be high, it is enough to ensure that the diffusion liquid has a stable rotation effect, so as to avoid the settlement of the diffusion particles due to the long-term standing of the diffusion liquid.

[0050] Spoon the spread from the bucket to the trough and start the machine to start coating. The running speed of the machine is 30 m / min, the setting temperature of the oven is 120 degrees Celsius, and the length of the oven is 20 meters. The diffusion liquid collected from the reflux of ...

Embodiment 3

[0058] Add 15 parts by mass of diffusion particles with a particle diameter of 15 microns, 25 parts by mass of resin and 60 parts by mass of solvent into the pneumatic stirring tank, stir and disperse evenly. Then filter the dispersed dispersion liquid into a clean bucket through a 300-mesh filter bag.

[0059] Move the barrel to the side of the coating equipment, add a stirring device on the barrel, and start the stirring device to maintain a slow speed. Spoon the spread from the bucket to the trough and start the machine to start coating. The running speed of the machine is 30 m / min, the setting temperature of the oven is 120 degrees Celsius, and the length of the oven is 20 meters. The diffusion liquid collected from the reflux of the feed tank can be used again.

[0060] After winding, place the mother roll coated with diffusion layer in a curing room at 60 degrees Celsius for 48 hours.

[0061] Add 8 parts by mass of anti-adhesive particles with a particle size of 10 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com