Seal agent curing device

A technology of curing device and sealant, which is applied to devices, optics, instruments and other directions for coating liquid on the surface. The step of moving to the thermal curing device, the effect of improving the utilization rate, and improving the degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

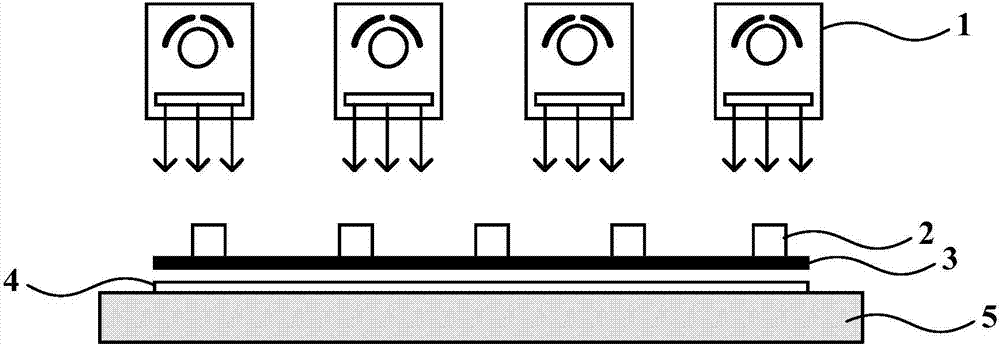

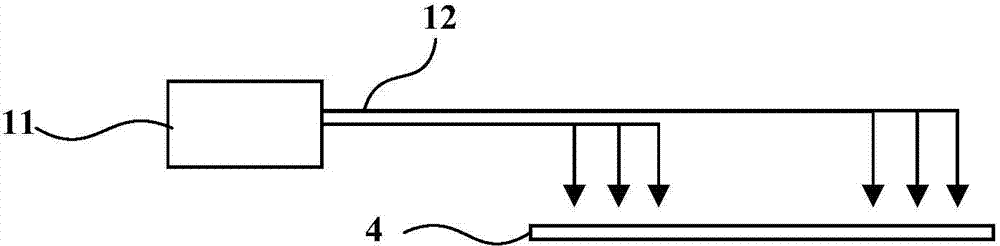

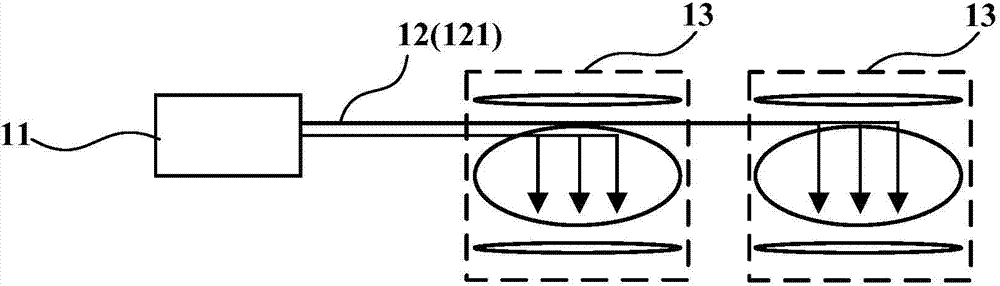

[0039] In order to improve the utilization rate of light energy, an embodiment of the present invention provides a frame sealing glue curing device. In this technical solution, an ultraviolet laser and an ultraviolet optical fiber for transmitting ultraviolet laser are used, and the ultraviolet light output from the light output end of the optical fiber group is directly irradiated on the pre-cured sealing glue, which avoids the ultraviolet light blocking caused by the existing mask plate. The energy waste is greatly improved, and the utilization rate of light energy is greatly improved, and the mask plate is not required in the device, and the mask plate does not need to be replaced when replacing different substrates, so the production efficiency can also be greatly improved. In order to make the purpose, technical solution and advantages of the present invention clearer, the following specific examples are given to further describe the present invention in detail.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com