A kind of high-load lithium-manganese battery and preparation method thereof

A lithium-manganese battery, high-load technology, applied to the electrodes of primary batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve problems such as affecting the use of the instrument, the instrument cannot be started, and the valve can be opened, and achieves reduction of material types and current conduction. Better outcomes, lower risk outcomes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

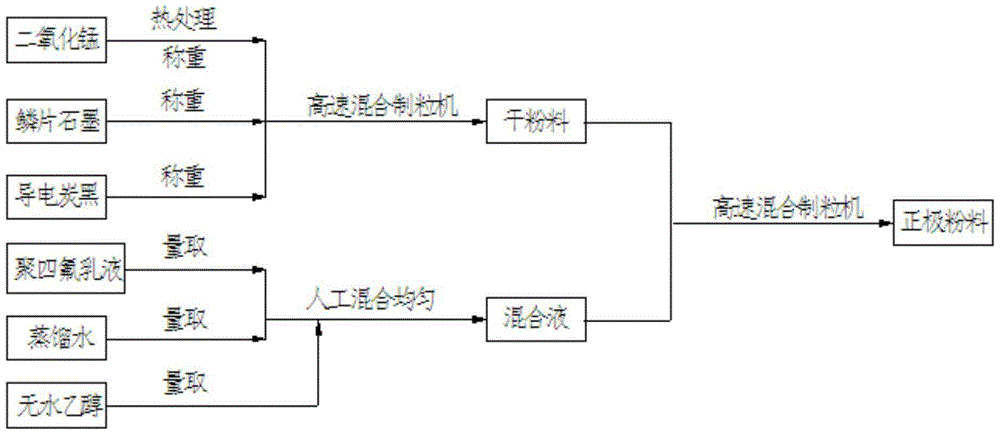

Image

Examples

Embodiment 1

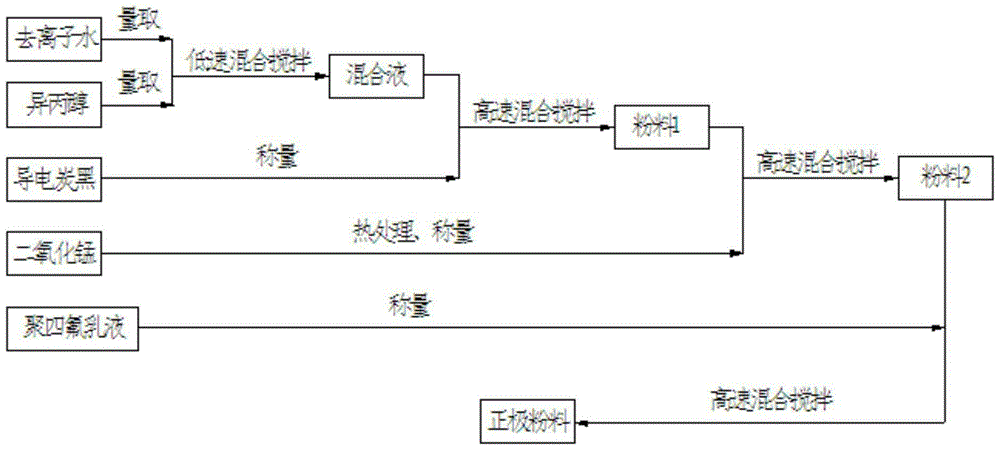

[0026] like figure 2 As shown, the process for preparing high-load lithium-manganese batteries is as follows:

[0027] 1. Weigh 40kg of electrolytic manganese dioxide powder, bake in a high-temperature oven at 380±5°C for 12 hours, then cool for later use; the purity of the manganese dioxide is 92%;

[0028] 2. Inject 2kg of isopropanol and 15kg of deionized water into the high-speed mixing granulator. After adding the liquid materials, turn on the low speed gear and stir for more than 30s;

[0029] 3. After the stirring is stopped, add 2.7kg of conductive carbon black to the granulator. After adding the conductive agent, first keep stirring at low speed for 30 seconds, then change the stirring speed to high speed and stir for more than 3 minutes;

[0030] 4. After the stirring of the conductive agent is stopped, add the prepared electrolytic manganese dioxide powder into the granulator, the stirring speed is still at high speed, and stir for more than 5 minutes;

[0031] 5...

Embodiment 2

[0033] The process for preparing high-load lithium-manganese batteries is as follows:

[0034] 1. Weigh 60kg of electrolytic manganese dioxide powder, bake it in a high-temperature oven at 380±5°C for 12 hours, and then cool it for later use; the purity of the manganese dioxide is 92%;

[0035] 2. Inject 4kg of isopropanol and 25kg of deionized water into the high-speed mixing granulator. After adding the liquid materials, turn on the low speed gear and stir for more than 30s;

[0036] 3. After the stirring is stopped, add 5kg of conductive carbon black to the granulator. After adding the conductive agent, first maintain the low-speed stirring for 30s, then change the stirring speed to high-speed and stir for more than 3 minutes;

[0037] 4. After the stirring of the conductive agent is stopped, add the prepared electrolytic manganese dioxide powder into the granulator, the stirring speed is still at high speed, and stir for more than 5 minutes;

[0038] 5. After the stirring...

Embodiment 3

[0040] The process for preparing high-load lithium-manganese batteries is as follows:

[0041] 1. Weigh 65kg of electrolytic manganese dioxide powder, bake it in a high-temperature oven at 380±5°C for 12 hours, and then cool it for later use; the purity of the manganese dioxide is 92%;

[0042] 2. Inject 4kg of isopropanol and 20kg of deionized water into the high-speed mixing granulator. After adding the liquid materials, turn on the low speed gear and stir for more than 30s;

[0043] 3. After the stirring is stopped, add 3kg of conductive carbon black to the granulator. After adding the conductive agent, first maintain the low-speed stirring for 30s, then change the stirring speed to high-speed and stir for more than 3 minutes;

[0044] 4. After the stirring of the conductive agent is stopped, add the prepared electrolytic manganese dioxide powder into the granulator, the stirring speed is still at high speed, and stir for more than 5 minutes;

[0045] 5. After the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com