Carbon-based electrode material, preparation method of carbon-based electrode material and energy storage device

An electrode material, carbon-based technology, used in capacitors, electrical components, battery electrodes, etc., can solve the problems of complex processes and complicated steps, and achieve the effects of simple steps, cheap and easily available raw materials, and long cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention provides a method for preparing a carbon-based electrode material, comprising the following steps:

[0044] a) heat-treating the pine needles in an inert atmosphere to obtain the first carbon-based electrode material;

[0045] b) mixing the first carbon-based electrode material obtained in step a) with an alkaline substance to obtain a mixture;

[0046] c) chemically activating the mixture obtained in step b) under an inert atmosphere to obtain a second carbon-based electrode material.

[0047] In the invention, pine needles are used as raw materials, and the first carbon-based electrode material is obtained after heat treatment; the obtained first carbon-based electrode material is mixed with an alkaline substance and then chemically activated to obtain the second carbon-based electrode material. The method provided by the invention has rich sources, simple preparation process and easy control, and the obtained carbon-based electrode material has better ...

Embodiment 1

[0089] Wash the pine needles with water, then sonicate them for 10 minutes, then wash them with ethanol or acetone, then sonicate them for 10 minutes, and finally wash them with distilled water. Dry the obtained clean pine needles at 70°C for later use.

[0090] The above-mentioned dried pine needles were heated for 2 hours under the protection of nitrogen atmosphere, and the heating temperature was 500° C. to obtain the first carbon-based electrode material.

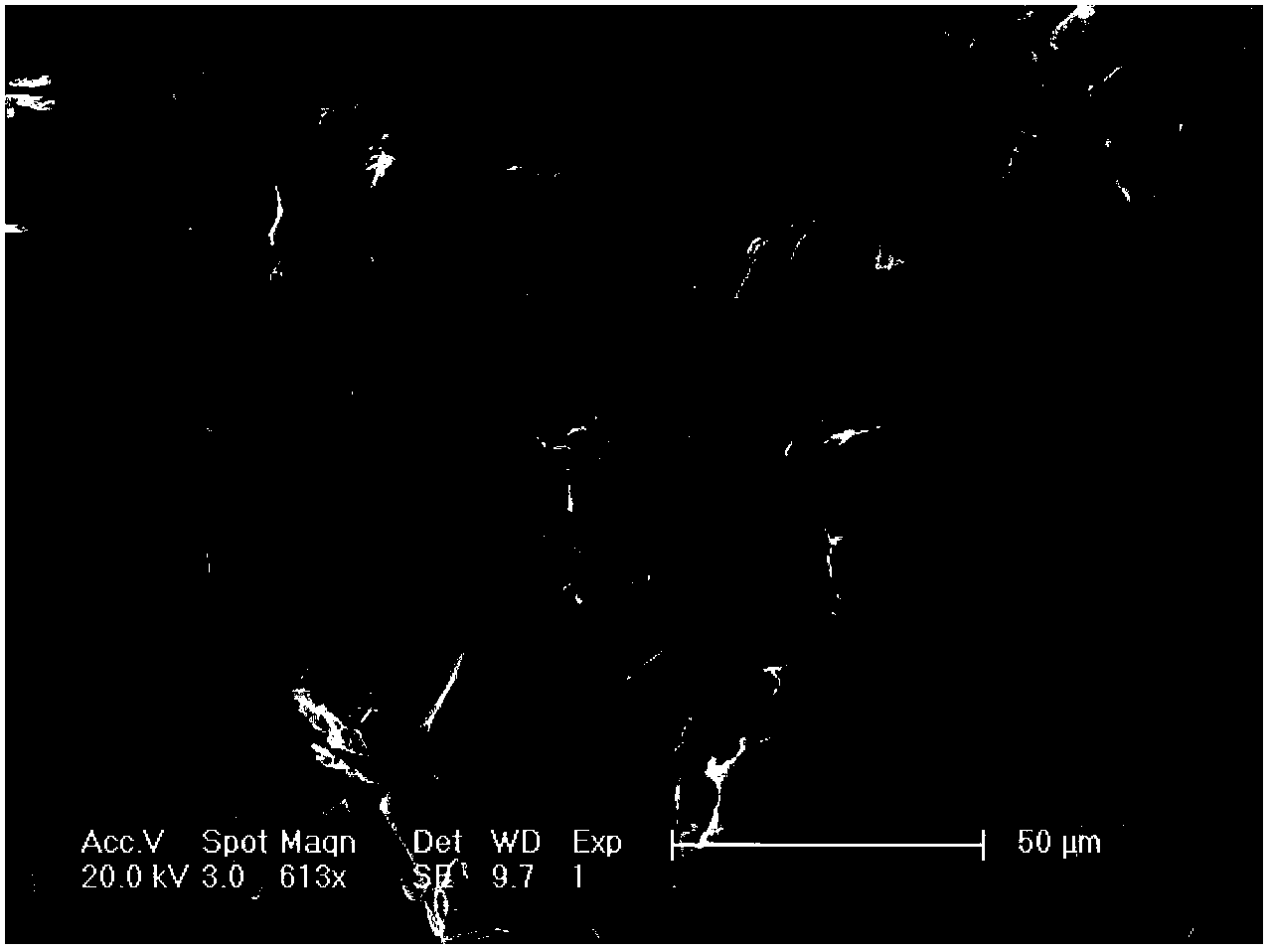

[0091] The present invention uses a scanning electron microscope to characterize the morphology of the obtained first carbon-based electrode material, and the results are as follows figure 1 as shown, figure 1 It is the SEM figure of the first carbon-based electrode material that the embodiment of the present invention 1 obtains, by figure 1 It can be seen that the first carbon-based electrode material obtained in this embodiment has a porous structure.

[0092] The present invention adopts automatic specific surface ...

Embodiment 2

[0094] The dried pine needles obtained in Example 1 were heated under the protection of nitrogen atmosphere for 3 hours, and the heating temperature was 600° C. to obtain the first carbon-based electrode material.

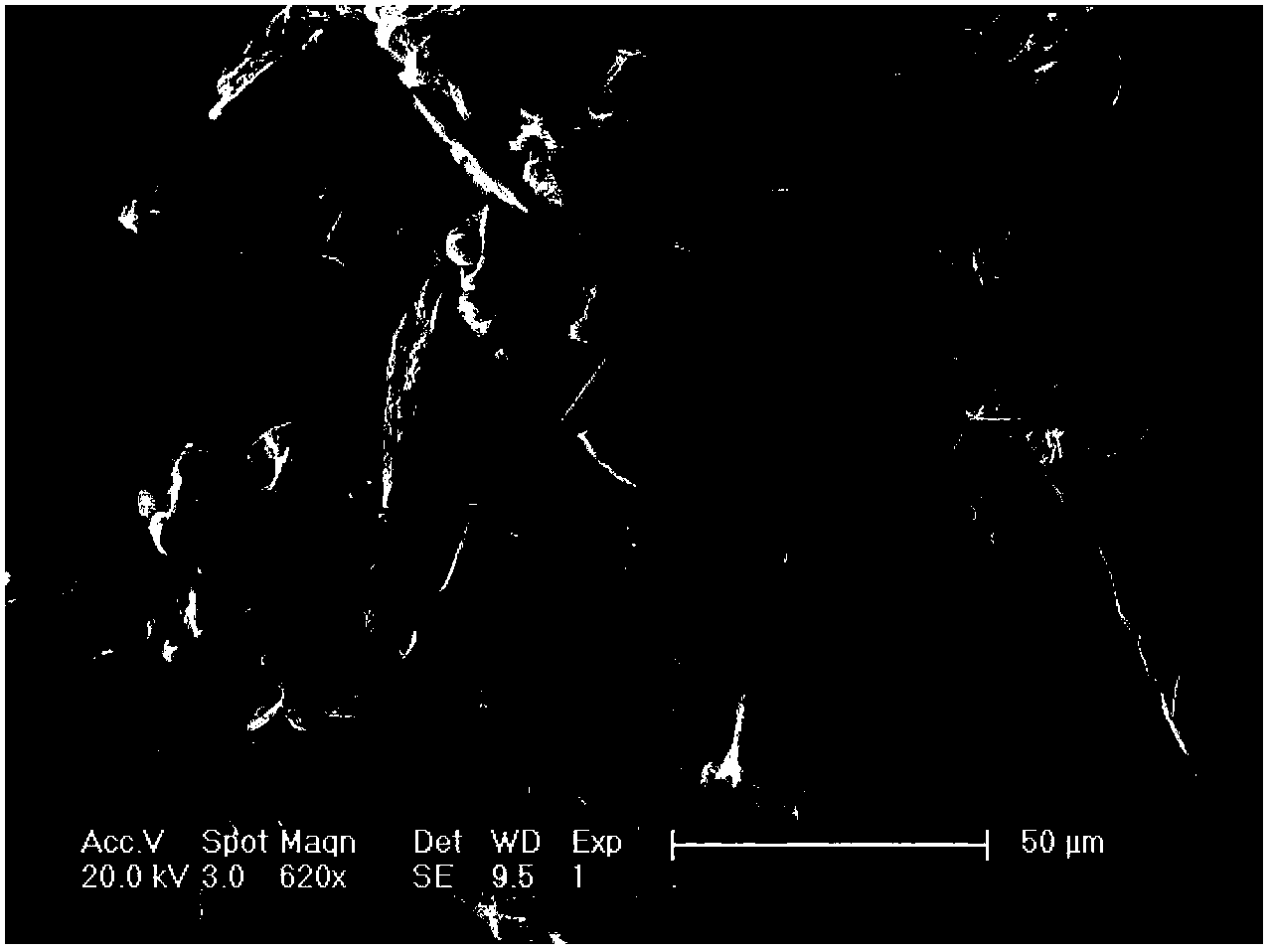

[0095] The present invention uses a scanning electron microscope to characterize the morphology of the obtained first carbon-based electrode material, and the results are as follows image 3 as shown, image 3 The SEM figure of the first carbon-based electrode material that is the embodiment of the present invention 2 obtains, by image 3 It can be seen that the first carbon-based electrode material obtained in this embodiment has a porous structure.

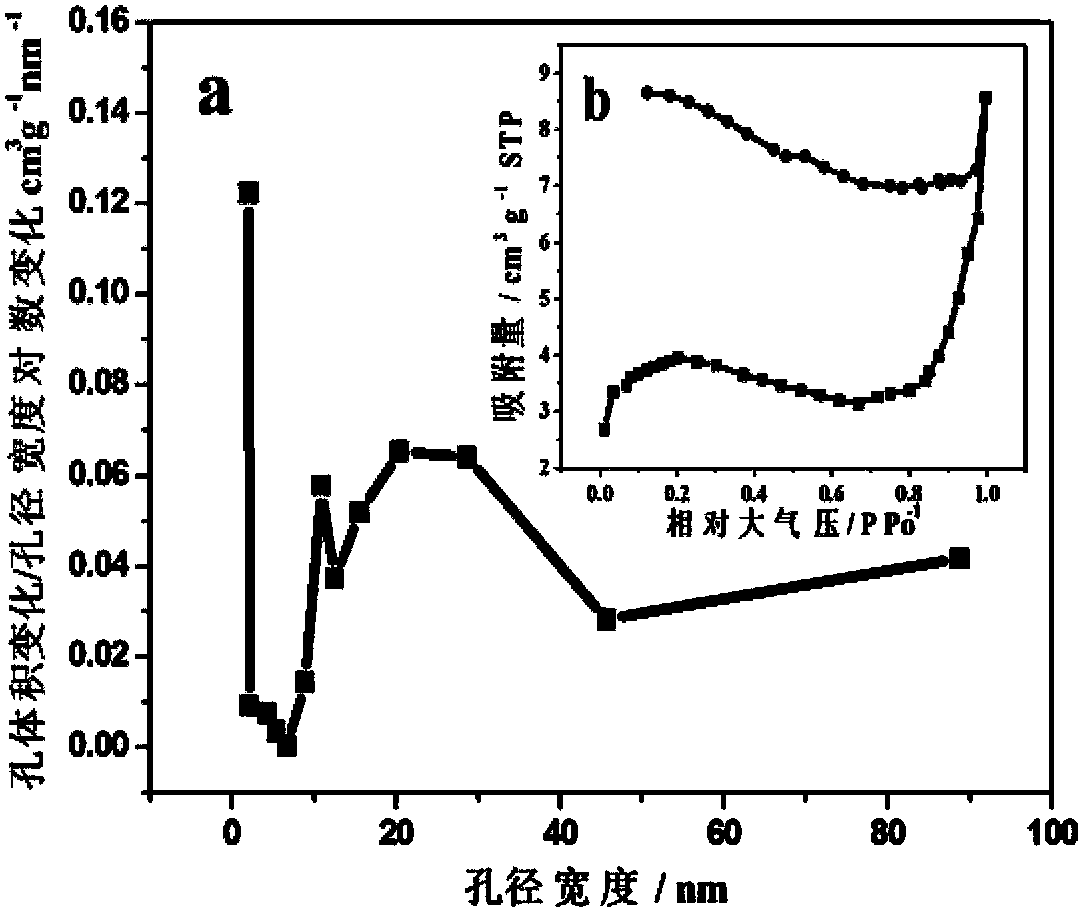

[0096] The present invention adopts automatic specific surface area and porous analyzer to characterize the specific surface area and pore size distribution of the first carbon-based electrode material obtained, and the results are as follows Figure 4 as shown, Figure 4 The BJH pore size distribution diagram and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com