Electric automobile

A technology for electric vehicles and battery packs, applied in the direction of batteries, circuits, electrical components, etc., can solve the problems of simple cooling device, poor cooling effect, combustion, etc., and achieve good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

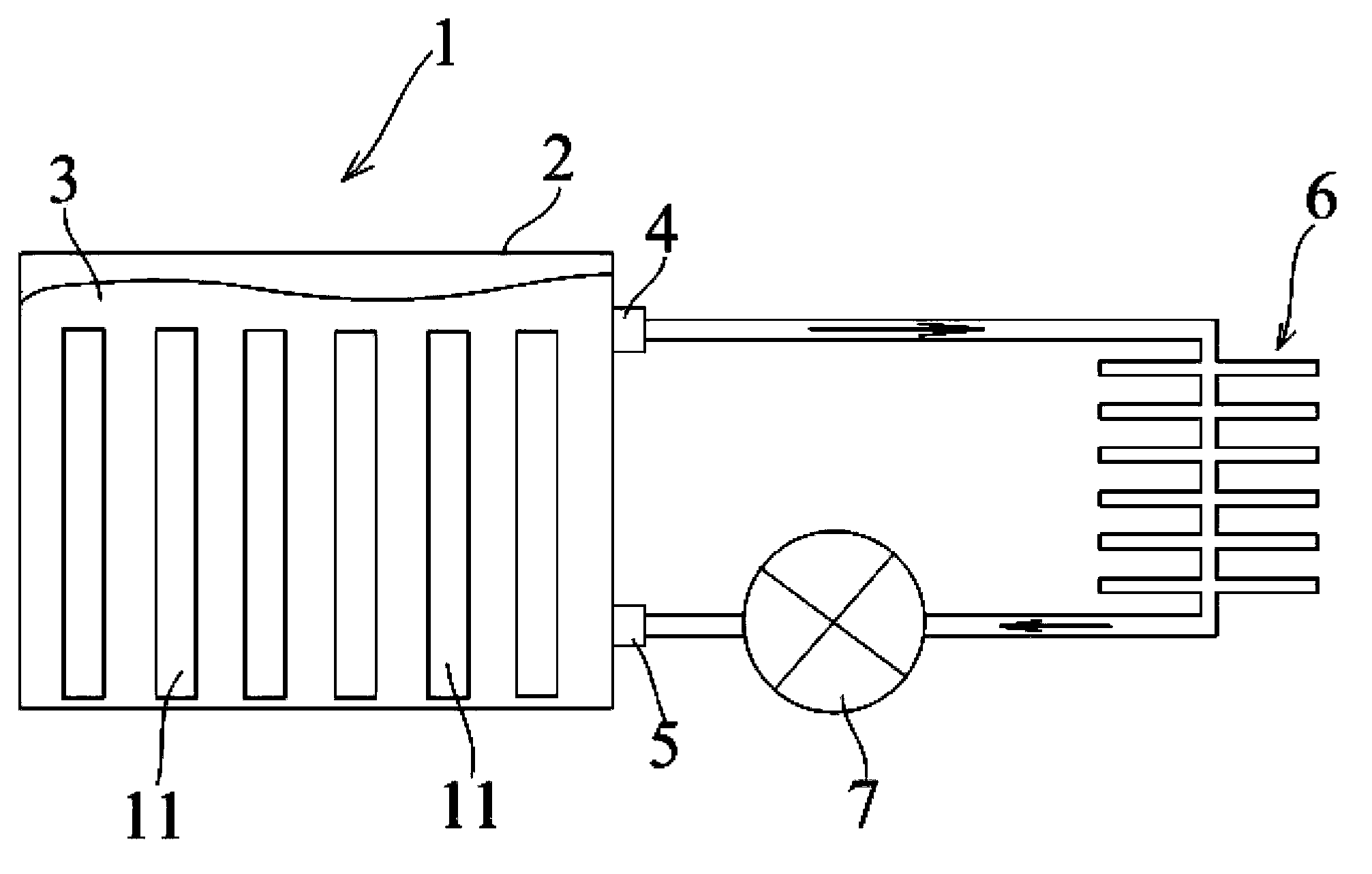

[0027] Such as figure 1 Illustrated: an electric vehicle, which includes a battery pack 1, the battery pack 1 includes a housing 2 and a plurality of battery cells 11 placed in the housing 1, filled in the housing 1 There is a silicone oil 3, and an outlet 4 and an inlet 5 are opened on the housing 1. The silicone oil can pass through the outlet 4 and return to the inlet 5 after passing through the cooling fin 6. Between the outlet 4 and the inlet 5, a device for driving the Pump 7 for silicone oil flow.

Embodiment 2

[0029] 1. An electric vehicle comprising a battery pack 1, said battery pack 1 comprising a housing 2 and a plurality of battery cells 11 placed in said housing 1, filled with Silicone oil 3, an outlet 4 and an inlet 5 are opened on the housing 1, and the silicone oil can pass through the outlet 4 and return to the inlet 5 after passing through the cooling fin 6, and a device for driving the Pump 7 for silicone oil flow.

[0030] The heat sink 6 is arranged on the top of the electric vehicle.

Embodiment 3

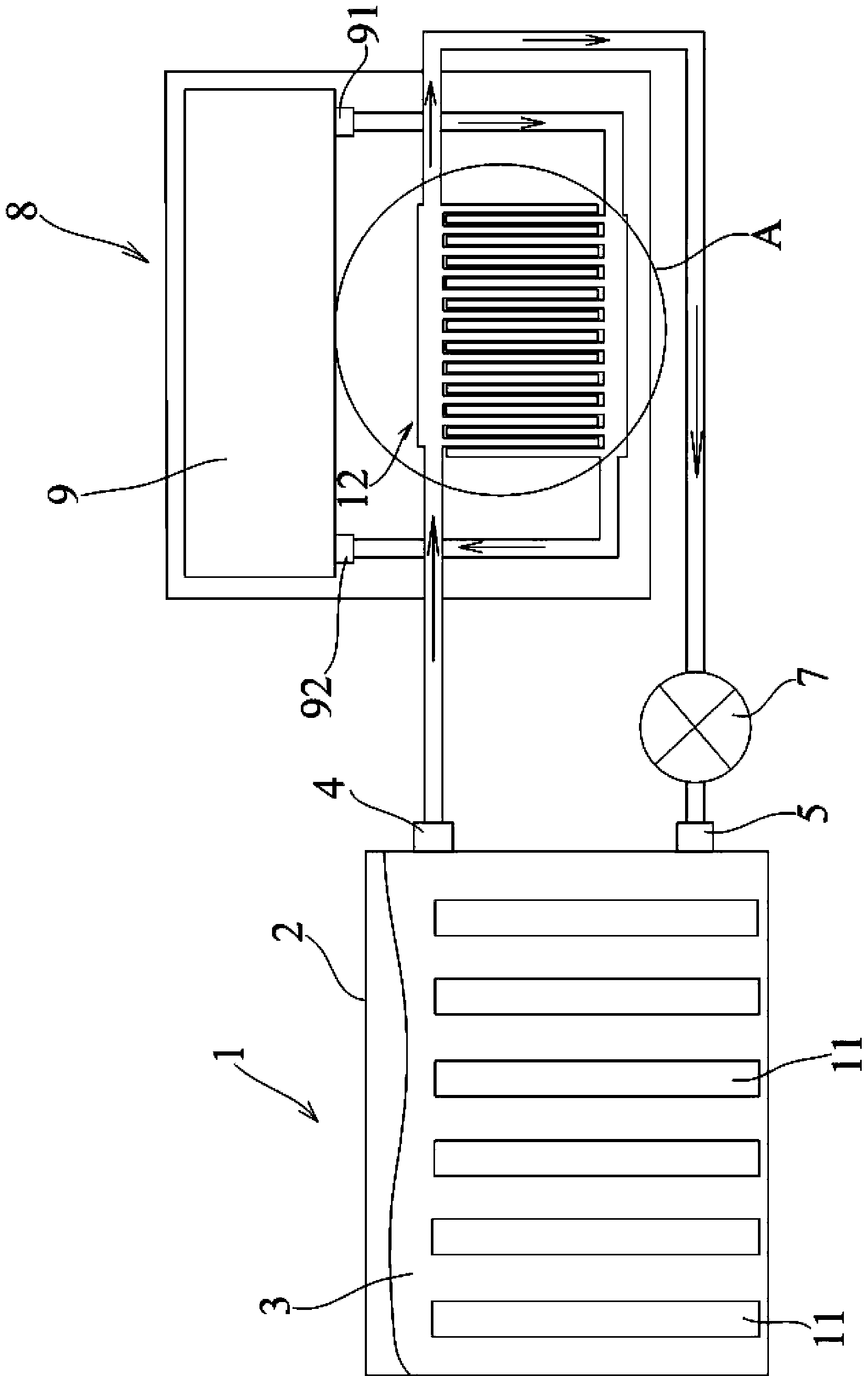

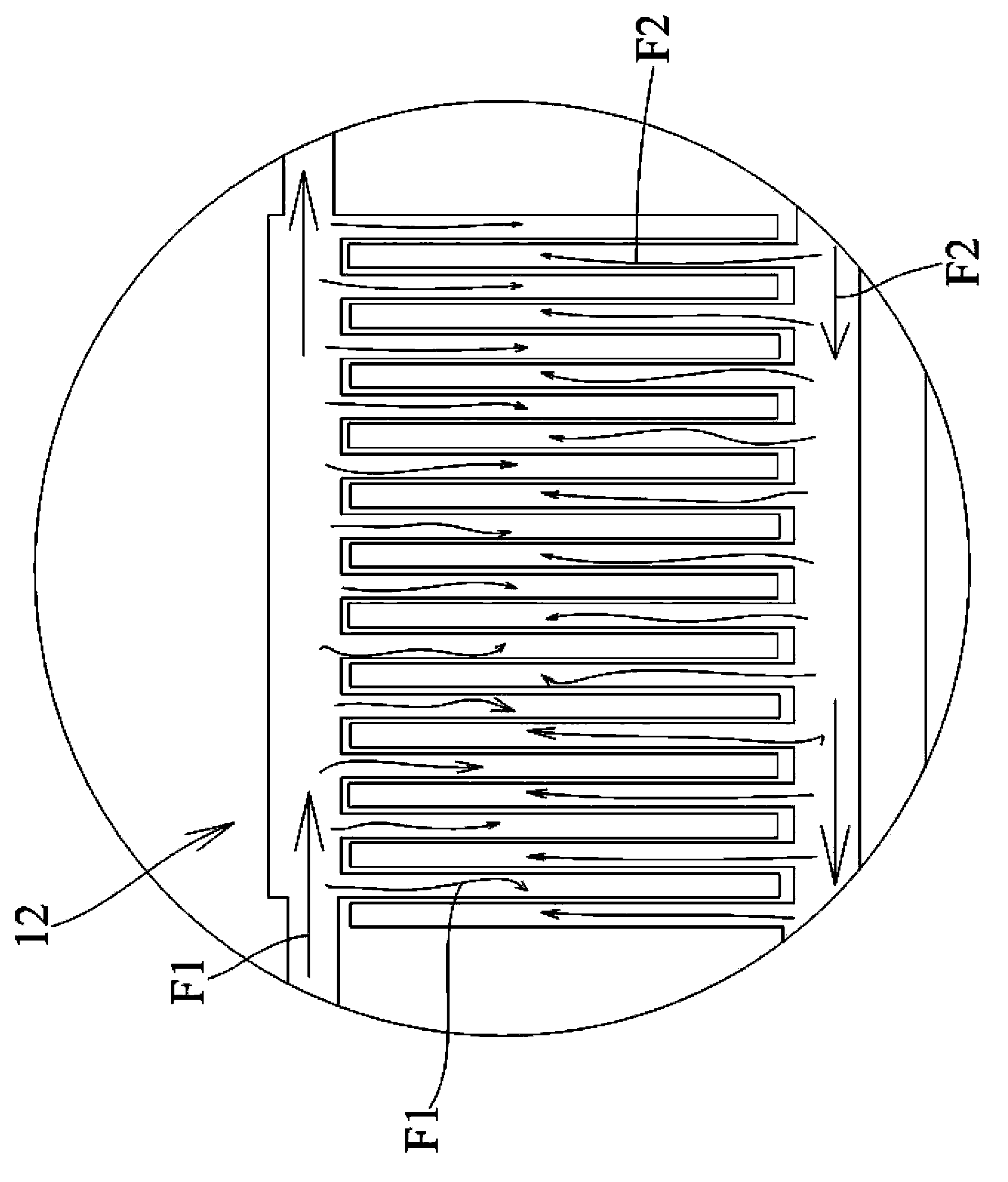

[0032] An electric vehicle, which includes a battery pack 1, the battery pack 1 includes a housing 2 and a plurality of battery cells 11 placed in the housing 1, and the housing 1 is filled with silicone oil 3 , an outlet 4 and an inlet 5 are opened on the housing 1, and the silicone oil can pass through the outlet 4 and return to the inlet 5 after passing through the heat sink 6. A device for driving the silicone oil to flow is provided between the outlet 4 and the inlet 5. the pump7.

[0033] The electric vehicle also includes an air conditioner, which is driven by the power supplied by the battery pack 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com