A battery management system for an electric vehicle and an electric vehicle

A technology of battery management system and electric vehicle, which is applied to electric vehicles, battery circuit devices, current collectors, etc., can solve the problems of long pulling of multiple sampling lines, reducing sampling accuracy, affecting the wiring of the whole vehicle, etc. The effect of strong performance, improved sampling accuracy, and simple vehicle layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

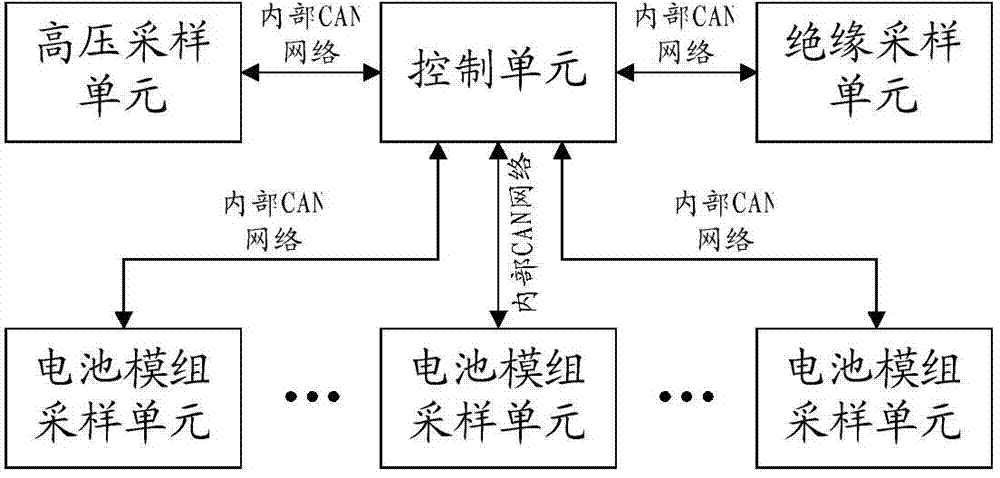

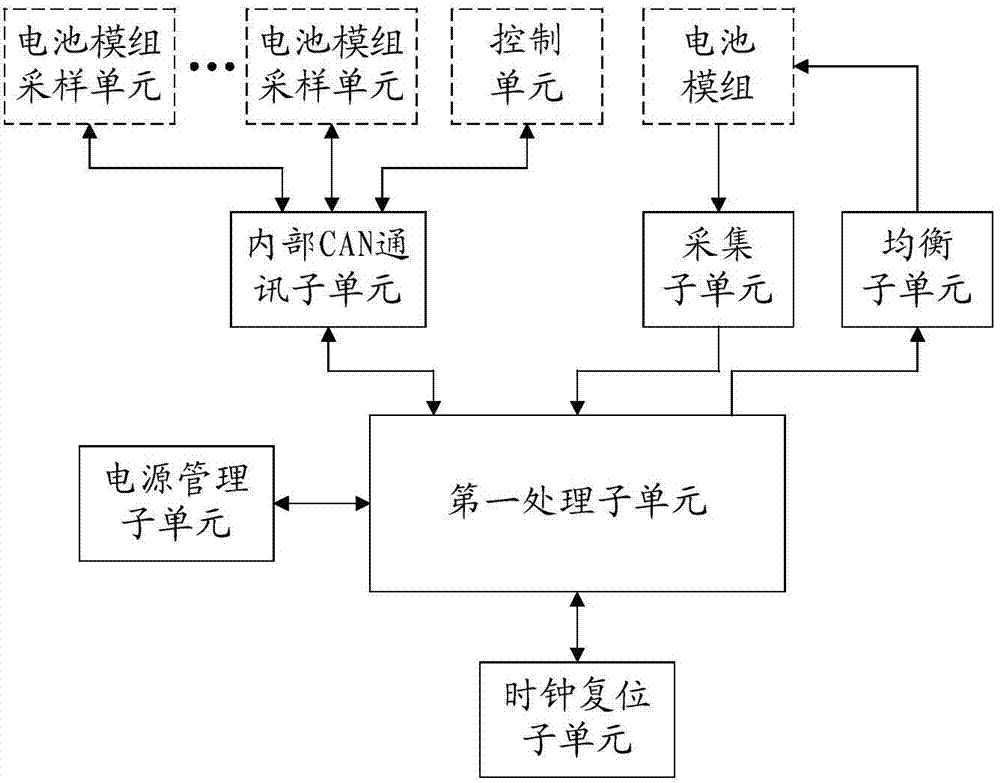

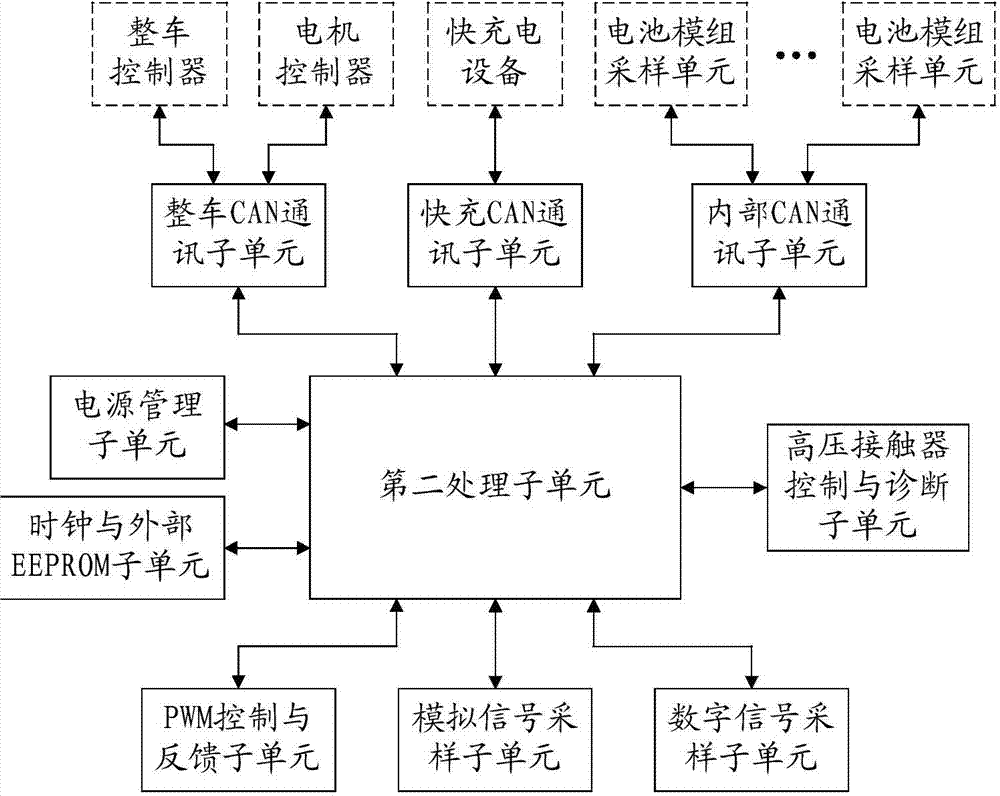

[0053] This embodiment provides a battery management system for an electric vehicle, the electric vehicle includes a battery pack composed of multiple battery modules connected in series, a vehicle management system (VMS, Vehicle Management System) and a motor controller (MCU, Motor Control Unit), where each battery module includes multiple single cells, for example, each battery module consists of multiple single cells connected in series and parallel. Such as figure 1 As shown, the battery management system includes: a plurality of battery module sampling units, a high voltage sampling unit, an insulation sampling unit and a control unit; each battery module sampling unit corresponds to a battery module.

[0054] Wherein, the battery module sampling unit is used to measure the voltage of each single battery in the corresponding battery module in real time, and send the measured value to the control unit through the internal CAN network. The control unit is used for balancin...

Embodiment 2

[0084] The difference between this embodiment and embodiment 1 is:

[0085] Such as Figure 4 As shown, the battery module sampling unit also includes: a hardware monitoring subunit; the collection subunit is also used to collect the temperature values of each single battery in the corresponding battery module in real time, and collect all the collected The temperature value and the voltage value are sent to the first processing subunit; the first processing subunit is also configured to send the temperature value and the voltage value collected by the collection subunit to the hardware monitoring subunit;

[0086]The hardware monitoring sub-unit is used to perform real-time redundant monitoring on the voltage value and temperature value of each single cell in the corresponding battery module collected by the collection sub-unit, so as to judge the voltage value of each single cell in the corresponding battery module Whether it is overcharged, overdischarged or overtemperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com