Adaptive drive method for synchronous rectification of flyback converter

A flyback converter, synchronous rectification technology, applied in the direction of converting DC power input to DC power output, instruments, adjusting electrical variables, etc. Easy to stabilize, reduce light load loss and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

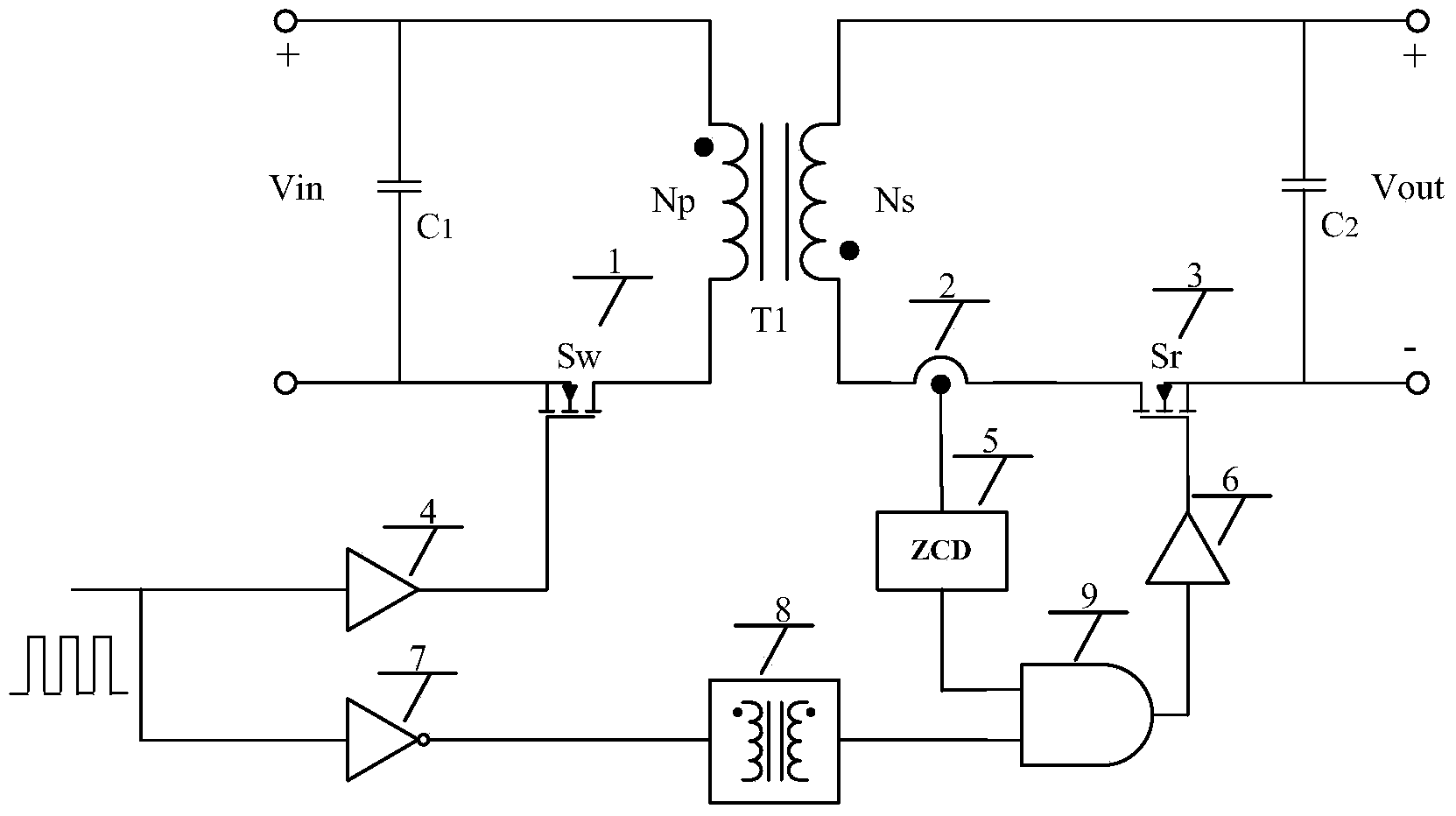

[0029] Such as image 3 Shown is the circuit composition diagram for realizing the method of the present invention, in order to realize the self-adaptive regulation of the load variation of the synchronous rectifier drive signal of the secondary side, the circuit composition diagram for realizing the method of the present invention includes the main circuit flyback converter Using synchronous rectification topology, primary side drive tube 1, secondary side rectification drive tube 3, secondary side current detection circuit 2, current zero-crossing detection (ZCD) 5, AND gate logic circuit 9, isolation circuit 8, drive circuits 4 and 6 and reverse circuit 7.

[0030] Set the duty ratio of the PWM signal driven by the primary side to D, and obtain the PWM signal through the reverse circuit 7 with a duty ratio of 1-D.

[0031] When the flyback converter works under heavy load conditions and the circuit works in the current continuous mode, the primary and secondary currents ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com