A kind of preparation technology of whey lactic acid bacteria fermentation liquid with excellent whipping properties

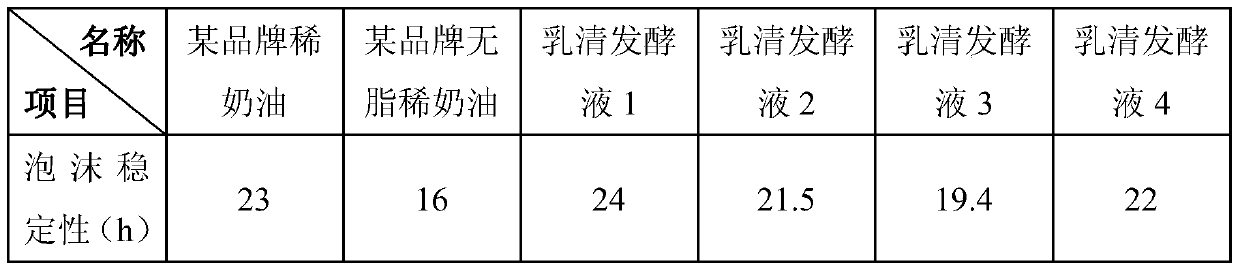

A technology of lactic acid bacteria fermented liquid and fermented liquid, which is applied in the field of exopolysaccharides to increase whipping foam retention and add colloids, which can solve the problems of poor whipping performance and affect the application of fat-free cream, and achieve good foam stability and whipping effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Soluble powder: Dissolve whey protein powder into water to obtain a whey solution. The water temperature is generally controlled at 45°C; the formula of soluble powder is:

[0024] Whey protein powder 30%; water: 70%

[0025] The specification of whey protein powder is WPC34%, not resistant to high temperature

[0026] 2) Homogenization: Homogenization pressure is 25Mpa;

[0027] 3) Sterilization: Sterilize at 70°C for 25 minutes;

[0028] 4) Cooling: cooling to 43°C;

[0029] 5) Inoculation: Add lactic acid bacteria freeze-dried powder starter into the whey solution, the amount of which is 0.1%; the lactic acid bacteria freeze-dried powder is Lactobacillus paracasei, Lactobacillus acidophilus, Lactobacillus helveticus, Lactococcus lactis species, according to the proportion of 2:1:1:2 according to the number of bacteria;

[0030] 6) Fermentation: Ferment the inoculated whey solution at 43°C for 48 hours to form a fermentation broth;

[0031] 7) Aging: aging the...

Embodiment 2

[0036] 1) Soluble powder: Dissolve whey protein powder into water to obtain a whey solution. The water temperature is generally controlled at 55°C; the formula of soluble powder is:

[0037] Whey protein powder 20%; water: 80%

[0038] The specification of whey protein powder is WPC34%, not resistant to high temperature

[0039] 2) Homogenization: Homogenization pressure is 25Mpa;

[0040] 3) Sterilization: Sterilization temperature 65°C, 30min;

[0041] 4) Cooling: cooling to 37°C;

[0042] 5) Inoculation: add lactic acid bacteria freeze-dried powder starter into the whey solution, 0.01%; : The ratio of 1:1:2 is proportioned according to the number of bacteria;

[0043] 6) Fermentation: Ferment the inoculated whey solution at 37°C for 24 hours to form a fermentation liquid;

[0044] 7) Aging: aging the fermentation broth at 0°C for 12 hours;

[0045] 8) Deployment: Dissolve 75% white granulated sugar solution first, heat up to 95°C, keep warm for 10 minutes, and then co...

Embodiment 3

[0049] 1) Soluble powder: Dissolve whey protein powder into water to obtain a whey solution. The water temperature is generally controlled at 50°C; the formula of soluble powder is:

[0050] Whey Protein Powder 25%; Water: 75%

[0051] The specification of whey protein powder is WPC34%, not resistant to high temperature

[0052] 2) Homogenization: Homogenization pressure is 20Mpa;

[0053] 3) Sterilization: Sterilization temperature 65°C, 25min;

[0054] 4) Cooling: cooling to 43°C;

[0055] 5) Inoculation: add lactic acid bacteria freeze-dried powder starter into the whey solution, 0.1%; : The ratio of 1:1:2 is proportioned according to the number of bacteria;

[0056] 6) Fermentation: Ferment the inoculated whey solution at 43°C for 48 hours to form a fermentation broth;

[0057] 7) Aging: aging the fermentation broth at 4°C for 24 hours;

[0058] 8) Deployment: Dissolve 75% white granulated sugar solution first, heat up to 95°C, keep warm for 8 minutes, and then cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com