Composite modified starch for replacing fat as well as preparation method and application thereof

A composite modification and starch technology, which is applied in applications, baked foods with modified ingredients, dairy products, etc., can solve the problems of high processing cost of fat substitutes, affecting food sensory properties, etc., and achieve good foam retention and mechanical resistance The effect of strong performance and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

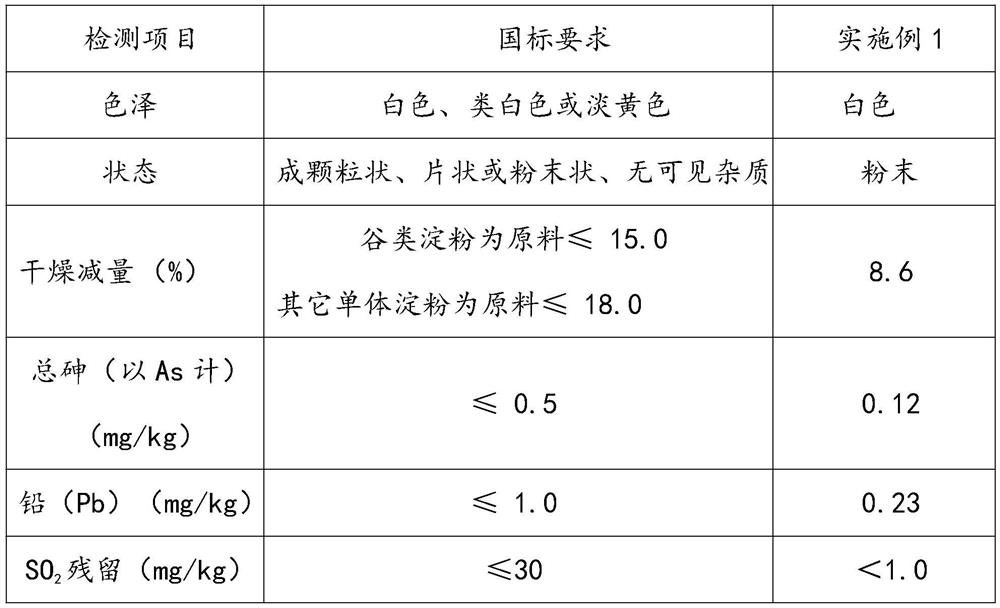

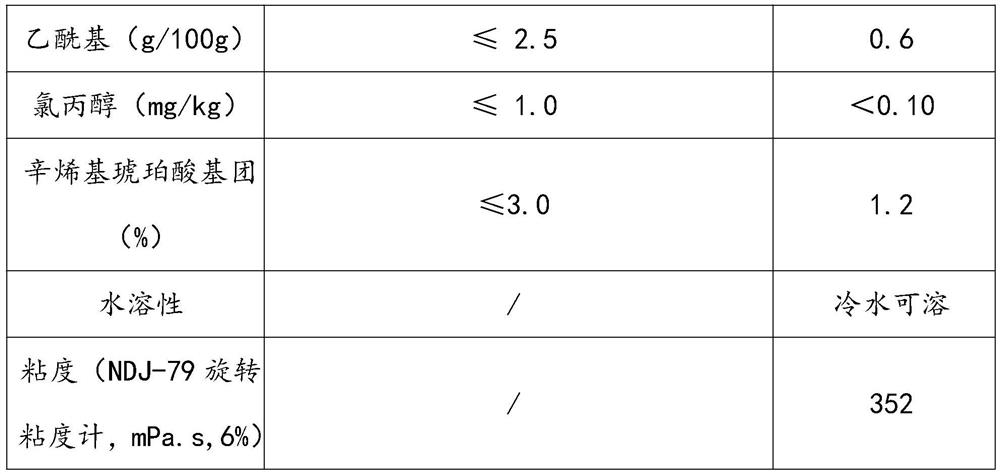

Examples

Embodiment 1

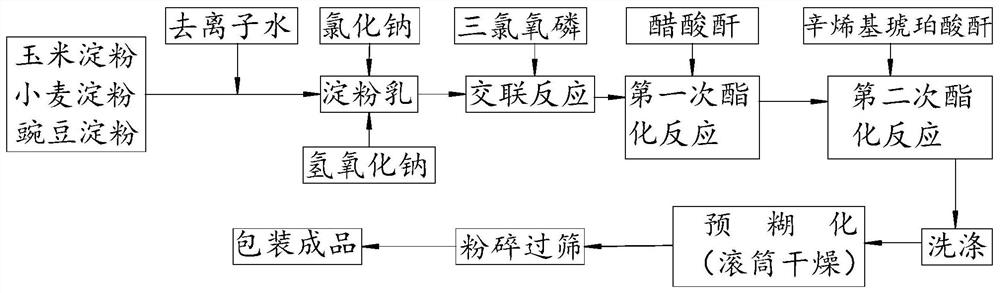

[0041] Please refer to the attached figure 1 A method for preparing composite modified starch for fat replacement provided by the invention, comprising the following steps:

[0042] (1) Sizing: According to the mass ratio, take 65% of corn starch and 35% of wheat starch as raw materials, mix them evenly to obtain mixed starch, add a certain amount of deionized water into the reaction vessel, and add 0.1% of the weight of mixed starch in the stirring state Sodium chloride, stir to make it fully dissolve, after no sodium chloride dissolves, add mixed starch to the solution, stir to form a uniform starch milk, the starch milk mass concentration is 36%;

[0043] (2) Alkalization: Weigh 99% caustic soda to prepare a sodium hydroxide solution with a mass concentration of 3.0%, and slowly add the sodium hydroxide solution to the starch milk to make the pH of the starch milk reach 11.2;

[0044] (3) Cross-linking: add a cross-linking agent phosphorus oxychloride solution to the starc...

Embodiment 2

[0054] A kind of preparation method of composite modified starch for replacing fat provided by the invention comprises the following steps:

[0055] ⑴Mulching: According to the mass ratio, take 30% corn starch, 40% wheat starch, and 30% pea starch as raw materials, mix them evenly to obtain mixed starch, add a certain amount of deionized water into the reaction vessel, and add the mixed starch under stirring 0.5% sodium chloride by weight of the starch, stirred to make it fully dissolve, after dissolving without sodium chloride, add mixed starch to the solution, stir to form a uniform starch milk, the mass concentration of the starch milk is 40%;

[0056] (2) Alkalization: Weigh 99% caustic soda to prepare a sodium hydroxide solution with a mass concentration of 3.0%, slowly add sodium hydroxide solution to the starch milk, so that the pH of the starch milk reaches 11.5;

[0057] (3) Cross-linking: add a cross-linking agent phosphorus oxychloride solution to the alkalized star...

Embodiment 3

[0067] A kind of preparation method of composite modified starch for replacing fat provided by the invention comprises the following steps:

[0068] ⑴Mulching: According to the mass ratio, take 30% corn starch, 30% wheat starch, and 40% pea starch as raw materials, mix them evenly to obtain mixed starch, add a certain amount of deionized water into the reaction vessel, and add the mixed starch under stirring 0.3% sodium chloride by weight of starch, stirred to make it fully dissolved, no sodium chloride dissolved, added mixed starch to the solution, stirred into uniform starch milk, the mass concentration of starch milk was 38%;

[0069] (2) Alkalization: Weigh 99% caustic soda to prepare a sodium hydroxide solution with a mass concentration of 3.0%, slowly add sodium hydroxide solution to the starch milk, so that the pH of the starch milk reaches 11.4;

[0070] (3) Cross-linking: add a cross-linking agent phosphorus oxychloride solution to the alkalized starch milk, the amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com