Preparation technology of whey lactic acid bacterium fermentation liquid with excellent whipping characteristic

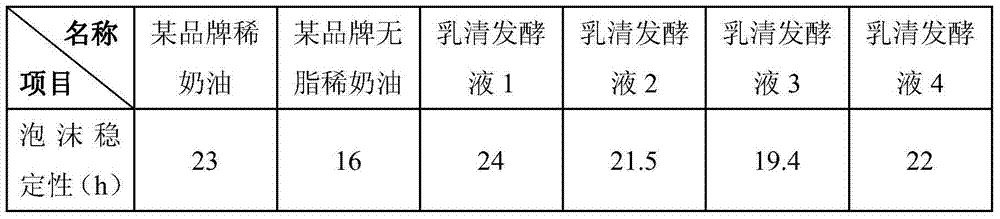

A lactic acid bacteria fermented liquid and a production process technology, applied in the field of whey fermented liquid, can solve the problems of poor whipping, affecting the application of non-fat cream, etc., and achieve the effects of good foam stability and good whipping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Soluble powder: Dissolve whey protein powder into water to obtain a whey solution. The water temperature is generally controlled at 45°C; the formula of soluble powder is:

[0024] Whey protein powder 30%; water: 70%

[0025] The specification of whey protein powder is WPC34%, not resistant to high temperature

[0026] 2) Homogenization: Homogenization pressure is 25Mpa;

[0027] 3) Sterilization: Sterilize at 70°C for 25 minutes;

[0028] 4) Cooling: cooling to 43°C;

[0029] 5) Inoculation: Add lactic acid bacteria freeze-dried powder starter into the whey solution, the amount of which is 0.1%; the lactic acid bacteria freeze-dried powder is Lactobacillus paracasei, Lactobacillus acidophilus, Lactobacillus helveticus, Lactococcus lactis species, according to the proportion of 2:1:1:2 according to the number of bacteria;

[0030] 6) Fermentation: Ferment the inoculated whey solution at 43°C for 48 hours to form a fermentation broth;

[0031] 7) Aging: aging the...

Embodiment 2

[0036] 1) Soluble powder: Dissolve whey protein powder into water to obtain a whey solution. The water temperature is generally controlled at 55°C; the formula of soluble powder is:

[0037] Whey protein powder 20%; water: 80%

[0038] The specification of whey protein powder is WPC34%, not resistant to high temperature

[0039] 2) Homogenization: Homogenization pressure is 25Mpa;

[0040] 3) Sterilization: Sterilization temperature 65°C, 30min;

[0041] 4) Cooling: cooling to 37°C;

[0042] 5) Inoculation: add lactic acid bacteria freeze-dried powder starter into the whey solution, 0.01%; : The ratio of 1:1:2 is proportioned according to the number of bacteria;

[0043] 6) Fermentation: Ferment the inoculated whey solution at 37°C for 24 hours to form a fermentation liquid;

[0044] 7) Aging: aging the fermentation broth at 0°C for 12 hours;

[0045] 8) Deployment: Dissolve 75% white granulated sugar solution first, heat up to 95°C, keep warm for 10 minutes, and then co...

Embodiment 3

[0049] 1) Soluble powder: Dissolve whey protein powder into water to obtain a whey solution. The water temperature is generally controlled at 50°C; the formula of soluble powder is:

[0050] Whey Protein Powder 25%; Water: 75%

[0051] The specification of whey protein powder is WPC34%, not resistant to high temperature

[0052] 2) Homogenization: Homogenization pressure is 20Mpa;

[0053] 3) Sterilization: Sterilization temperature 65°C, 25min;

[0054] 4) Cooling: cooling to 43°C;

[0055] 5) Inoculation: add lactic acid bacteria freeze-dried powder starter into the whey solution, 0.1%; : The ratio of 1:1:2 is proportioned according to the number of bacteria;

[0056] 6) Fermentation: Ferment the inoculated whey solution at 43°C for 48 hours to form a fermentation broth;

[0057] 7) Aging: aging the fermentation broth at 4°C for 24 hours;

[0058] 8) Deployment: Dissolve 75% white granulated sugar solution first, heat up to 95°C, keep warm for 8 minutes, and then cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com