Online vacuum oil-filtering treatment machine of oil

A technology of vacuum oil filter and processor, applied in filtration and separation, filter circuit, spray evaporation, etc., can solve the problems of inaccurate control of oil and foam, poor atomization effect, shortened life of vacuum pump, etc., to enhance the effective output power , better heating effect, improved vaporization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

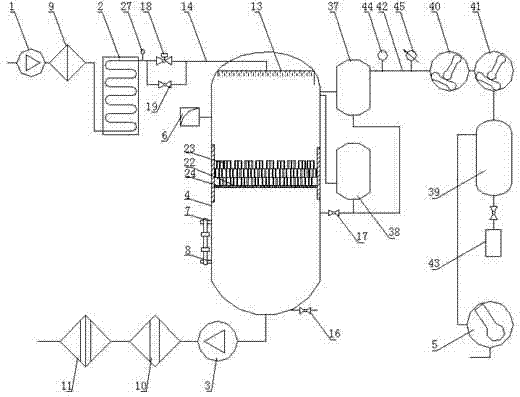

[0026] Such as figure 1 As shown, the oil online vacuum oil filter processing machine includes an oil inlet pump 1, an oil heater 2, a vacuum separation device, an oil outlet pump 3, a filter, an oil supply solenoid valve 18, a bypass valve 19, a foam sensor 6, and Infrared probe I7 for detecting upper oil level, infrared probe II8 for detecting lower oil level, condenser I37, condenser II38, condenser III39, Roots pump I40 and Roots pump II41. The vacuum separation device includes a vacuum tank 4 and an atomizer and a reaction rack arranged in the vacuum tank. An oil drain valve 16 is arranged at the bottom of the vacuum tank 4 , and a return valve 17 is arranged on the vacuum tank 4 and near the bottom of the reaction rack. The foam sensor 6 is arranged on the vacuum tank 4 and is located between the atomizer and the reaction rack....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com