Method for treating chrome tanning wastewater with flocculant

A flocculant and chrome tanning technology, which is applied in the field of flocculant treatment of chrome tanning wastewater, can solve the problems of high production cost and high toxicity of residual monomers, and achieve the effects of reducing treatment cost, good water purification effect and broad spectrum of methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of PAFS is: take ferric sulfate (Fe 2 SO 4 ·7H 2 O), aluminum sulfate (Al 2 (S0 4 ) 3 ,·18H 2 0), stirring, heating, until ferrous sulfate and aluminum sulfate are all melted, until the brownish-red product is obtained. The mass ratio of Fe / Al in PAFS is 11.

[0020] Make PAFS into a 50g / L flocculant solution, add it to the chrome tanning wastewater, react for 15 minutes, and let it stand for 24 hours.

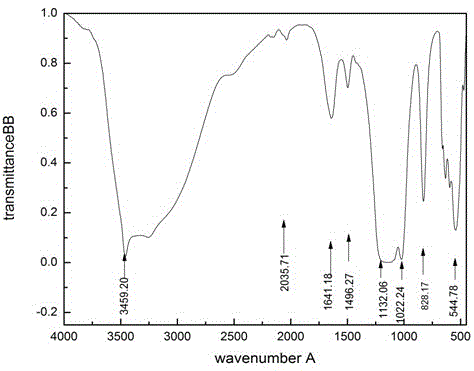

[0021] After PAFS was dried and pulverized in a drying oven at about 55°C, the potassium bromide tablet method was used to measure the infrared spectrum of the product with an infrared spectrometer. Using VECTOR-22 Fourier transform infrared spectrometer (Germany BRUKER company). As attached in the manual figure 1 shown.

[0022] From 3650-3200cm -1 It can be seen from the area of the absorption peak that the hydroxyl content in PAFS is relatively high, which is caused by OH - produced by group stretching vibrations. OH contained ...

Embodiment 2

[0026] The preparation method of PAFS is: take ferric sulfate (Fe 2 SO 4 ·7H 2 O), aluminum sulfate (Al 2 (S0 4 ) 3 ,·18H 2 0), stirring, heating, until ferrous sulfate and aluminum sulfate are all melted, until the brownish-red product is obtained. The mass ratio of Fe / Al in PAFS is 13.

[0027] Make PAFS into a 50g / L flocculant solution, add it to the chrome tanning wastewater, react for 15 minutes, and let it stand for 24 hours.

[0028] In the experiment, the treated chrome tanning wastewater was left to stand for 24 hours and then subjected to low-speed centrifugation. The amount of sediment was obtained by subtraction. The supernatant was taken and the absorbance was measured with a 7230G spectrophotometer (Shanghai Precision Scientific Instrument Co., Ltd.) to determine the flocculant. Chromium removal in wastewater;

[0029] Calculated by precipitation, the amount of precipitation was 1.25 g, and the absorbance was 0.045. The calculated residual amount of chro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com