Residual sludge ultrasonic-dehydration apparatus

A technology of excess sludge and dehydration device, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low dehydration rate, large land occupation, secondary pollution, high cost pretreatment, and high power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

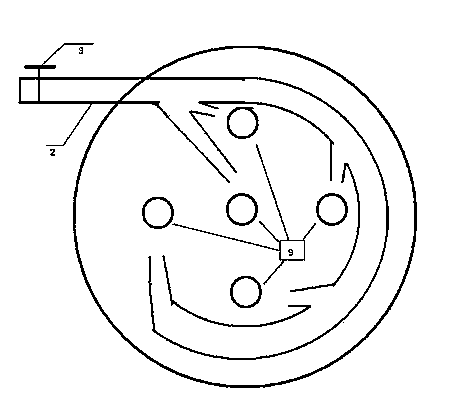

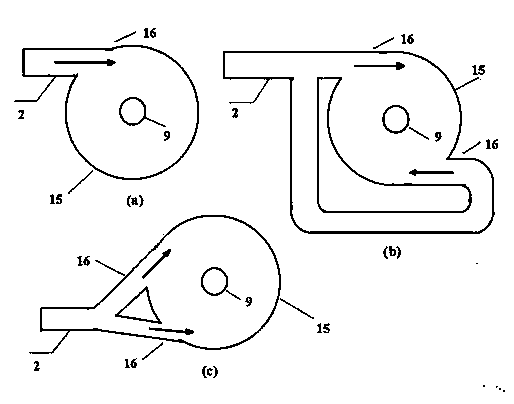

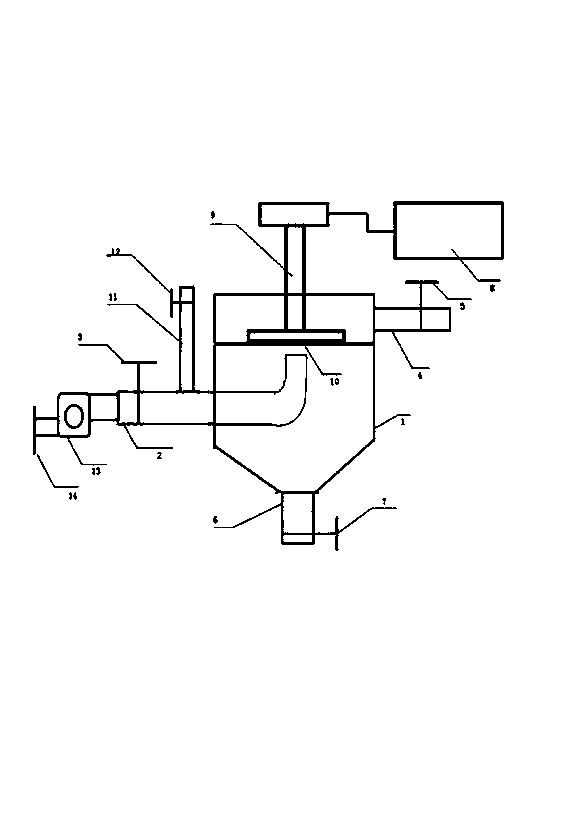

[0026] exist Figure 1-2 Among them, an ultrasonic dehydration device for excess sludge, comprising an ultrasonic reactor 1 for excess sludge dehydration, an excess sludge water supply pipeline 2, a water supply pipeline valve 3, a filtrate outlet pipeline 4, a concentrated sludge outlet pipeline 6, and an ultrasonic generator 8, Wherein said filtrate outlet pipeline 4 ports are provided with filtrate outlet pipeline valve 5, described concentrated sludge outlet pipeline 6 ports are provided with concentrated sludge outlet pipeline valve 7, are provided with adding flocculation on described excess sludge water supply pipeline 2 The pipeline 11 of the agent, the ultrasonic generator 8 is composed of an ultrasonic tuning module and an ultrasonic power amplifier, and there are several groups, each group excites an ultrasonic probe 9, and the ultrasonic probe 8 is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com