Treatment system and treatment process for organic waste gas boiler thermal incinerating

A technology of organic waste gas and treatment system, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of flammability and explosion, boiler corrosion, unstable air flow, etc., to ensure safety and stability, and improve purification efficiency , The effect of preventing pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

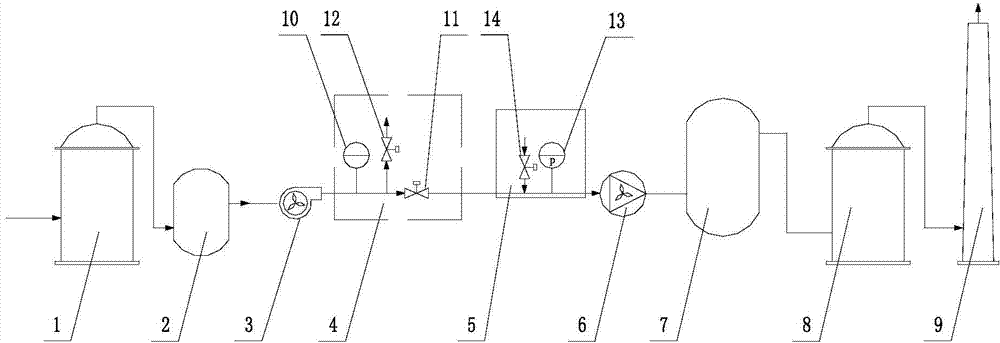

Method used

Image

Examples

Embodiment 1

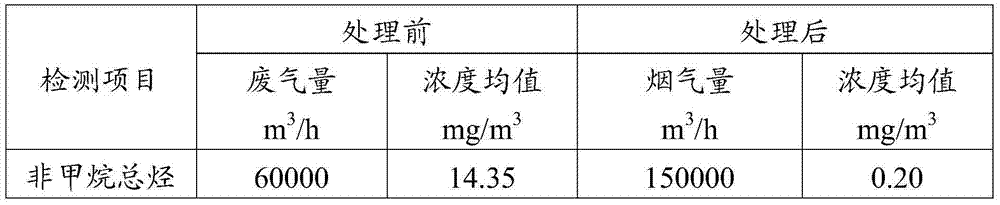

[0063] 60000m3 / h of organic waste gas from a medical and chemical enterprise first enters the alkali washing absorption device for pretreatment, and then passes through the demister, exhaust gas induced draft fan, emergency discharge controller, air volume balance compensator, and then enters the boiler for incineration treatment through the boiler fan. The exhaust gas enters the desulfurization and dust removal device for desulfurization and dust removal. The exhaust gas composition of this project is complex. After thermal incineration in the boiler, the purification efficiency of non-methane total hydrocarbons is >96%. The specific data of import and export are shown in Table 1.

[0064] Table 1 Non-methane total hydrocarbon monitoring value

[0065]

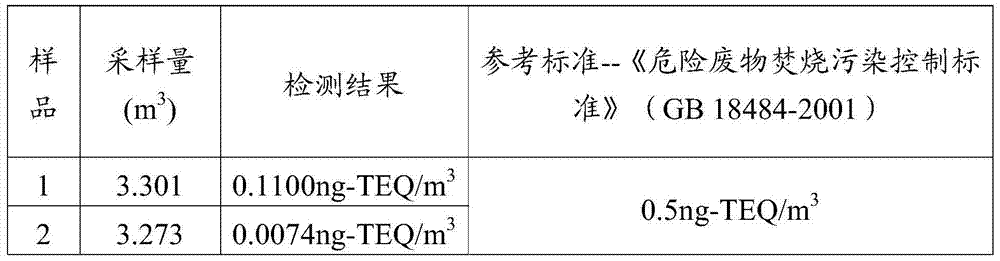

[0066] The composition of the organic waste gas of this project is complex, and the waste gas contains halogenated hydrocarbons such as dichloromethane. If the combustion conditions are not well controlled, secondary pollu...

Embodiment 2

[0070] The organic waste gas of a chemical company has a design air volume of 24500m3 / h. It first enters the adsorption or absorption device for pretreatment, and then enters three 130t / h fluidized bed coal-fired boilers through the boiler secondary fan for incineration treatment. The exhaust gas after it comes out enters the desulfurization process. The dust removal device performs desulfurization and dust removal treatment, and the total air volume of the flue gas is about 3000000m3 / h. It has been in operation for five years, and the thermal efficiency loss before and after waste gas incineration is about 1%. The boiler preheater is replaced once in the fourth year. The normal life of this type of boiler preheater is about 7 years.

[0071] Another medical and chemical enterprise’s organic waste gas has a designed air volume of 50,000m3 / h. Using the device of the present invention, it first enters the alkali washing absorption device for pretreatment, and then passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com