Appearance inspection method for white transparent silicon rubber seal ring

A technology of appearance inspection and sealing ring, which is applied in measuring devices, material analysis by optical means, instruments, etc., can solve problems such as low efficiency, high missed inspection rate, eye fatigue, etc., so as to improve inspection quality and reduce missed inspection rate. , the effect of improving the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

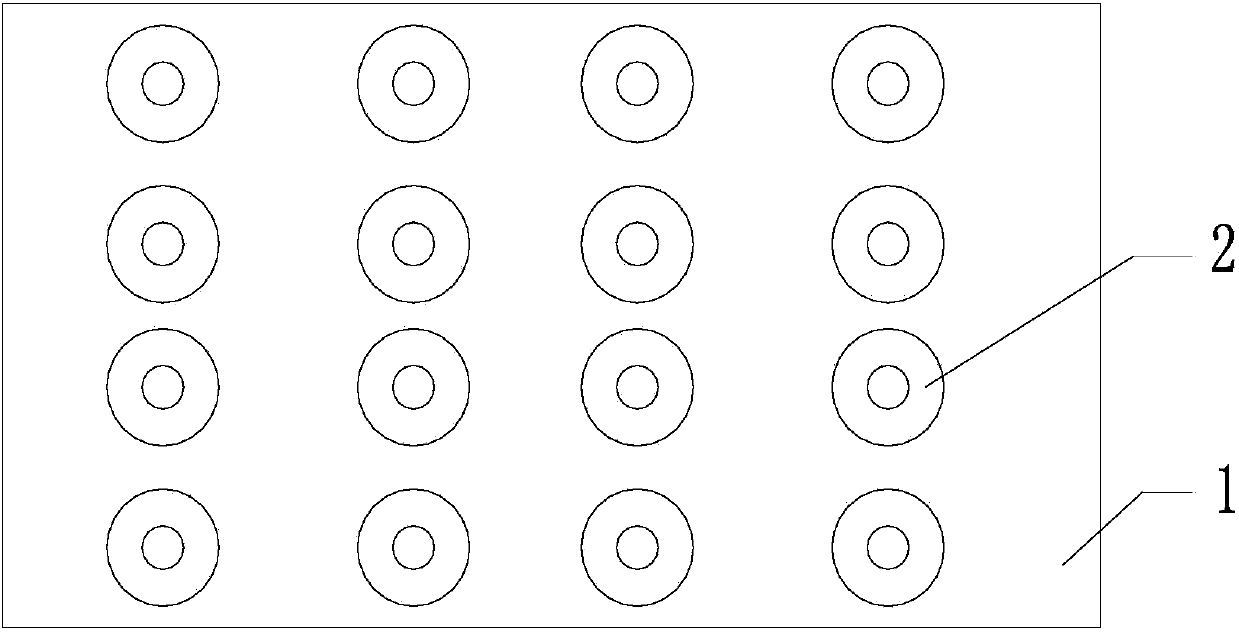

[0034] A method for visual inspection of a white transparent silicone rubber sealing ring, the steps of which are:

[0035] (1) Process two flat plates 1 of the same size. One flat plate 1 is placed on the inspection platform. The color of the flat plate 1 is modulated by the three primary colors of R, G, and U in the computer, where the value of R is 38, and the value of G is 73, The value of U is 146; the material of plate 1 is PVC, and the size is 240mm long x 150mm wide x 1.5mm thick;

[0036] (2) Use a fluorescent lamp with a pure white light color, the illuminance of the fluorescent lamp is 7000lux, the length of the fluorescent lamp is twice the length of the plate 1, the fluorescent lamp is parallel to the inspection platform, and the distance between the fluorescent lamp and the inspection platform is 450mm;

[0037] (3) Spread the white transparent silicone rubber sealing ring 2 to be tested on the flat plate 1 on the inspection platform, and the distance between eac...

Embodiment 2

[0045] Same as Example 1, the difference is: the value of R in step (1) is 43, the value of G is 62, and the value of U is 170; the illuminance of the fluorescent lamp in step (2) is 7800lux, and the length of the fluorescent lamp is equal to the plate 1 The fluorescent lamp is parallel to the inspection platform, and the distance between the fluorescent lamp and the inspection platform is 500mm; the distance between each sealing ring in step (3) is 3mm. The specifications of the tested white transparent silicone rubber sealing ring are 12.5mm in outer diameter and 5.8mm in thickness. Immediately select 40 inspection workers from a certain rubber factory, and randomly divide them into two groups, with 20 people in each group. The first group of workers uses the method of the present invention to detect, and the working hours are 8 hours. On average, each worker inspects white transparent silicone rubber. There were 7928.2 pieces of sealing rings, and there was no visual fatigu...

Embodiment 3

[0047] Same as Example 1, the difference is: the value of R in step (1) is 30, the value of G is 90, and the value of U is 138; the illuminance of the fluorescent lamp in step (2) is 5600lux, and the length of the fluorescent lamp is equal to the plate 1 The length of the fluorescent lamp is parallel to the inspection platform, and the distance between the fluorescent lamp and the inspection platform is 400mm; the distance between each sealing ring in step (3) is 6mm. The specifications of the tested white transparent silicone rubber sealing ring are 14mm in outer diameter and 5.8mm in thickness. The two groups of workers in Example 1 are reversed, and the second group of workers adopts the method of the present invention to detect. The working time is 9 hours. On average, each worker inspects 8895.1 pieces of white transparent silicone rubber sealing rings. Visual fatigue phenomenon, only three workers had slight eyestrain, and they returned to normal after a 5-minute rest; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com