Preparation method of co, mn coated high-nickel layered lini0.92co0.04mn0.04o2 lithium battery cathode material

A positive electrode material and lithium battery technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor battery cycle performance, poor lattice stability, and difficulty in meeting the requirements of high capacity and high cycle performance, etc., to achieve Effects of improving battery cycle performance, low cost, and improving lattice stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The method of the embodiment of the present invention comprises the following steps:

[0014] 1) Add a certain amount of distilled water and spherical Ni(OH) into the reactor 2 ;

[0015] 2) Stir at 500r / min under constant temperature conditions of 50°C, and add Co(NO 3 ) 2 and Mn(NO 3 ) 2 mixture;

[0016] 3) Add the mixed solution of ammonia water and NaOH, adjust the pH of the solution in the reaction kettle, keep the pH at 8-10, and make Co and Mn evenly precipitate into Ni(OH) 2 surface;

[0017] 4) after aging, washing and drying to obtain a precursor;

[0018] 5) Combine the precursor prepared above with LiOH·H 2 O is mixed evenly according to the molar ratio of 1:1.03;

[0019] 6) The mixed powder is sintered in a kiln. The temperature system is: 500°C for 5h, and then 700°C for 12h; the heating and cooling rates are both 2°C / min, and LiNi is obtained. 0.92 co 0.04 mn 0.04 o 2 Cathode material.

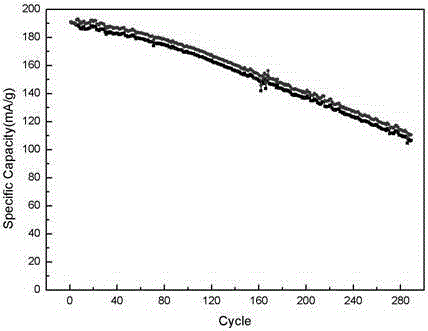

[0020] Detect and test the material obtained in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com