Method to extend whole grain flour and product shelf life

A technology for stabilizing flour, applied in the field of baked goods, stabilized whole grain flour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141] Part A. Acidification of Whole Grain Wheat

[0142] The goal of this example is to describe how to temper soft red wheat kernels with acid-containing water to produce non-bleaching whole grain flour with reduced pH. The starting wheat moisture was 13.05%, and the final grain moisture was increased to 14.0% by adding water to the wheat at ambient temperature and allowing the wheat to stand for 8 hours. Calculate the amount of water added according to Table 1.

[0143] Table 1

[0144]

[0145] program

[0146] A decontaminated wheat sample (800 g) was weighed in an airtight plastic bottle and mixed with the corresponding amount of tempered water containing the indicated amount of acid as shown in Table 2. The wheat was tempered for 8 hours at ambient temperature. For example, to achieve a lactic acid concentration of 850 ppm in 800 g of wheat, add 0.80 g of 85% lactic acid solution to 7.88 g of tap water. When the acid-containing moisturizing water is added ...

Embodiment 2

[0168] Coarsely ground bran is produced from acid-treated grain and reconstituted into whole grain flour

[0169] The objective of this procedure is to reduce the particle size of the coarse bran fraction obtained from the milling of acid-treated wheat and the sieve from the comminution system. The coarse bran from the first crushing roll and the coarse sieve from the pulverizing roll were frozen in liquid nitrogen in a sealed bottle and then ground by a Perten Laboratory Mill 3100 (Perten, Sweden) with the hammer set at 16,800 rpm, The mesh size is 0.5 mm. After grinding, the coarsely ground material is reconstituted with the remaining flour fraction (broken flour + flour from the shredding system) to form whole grain flour. Whole grain flour particle size distribution was determined by Roto Tap. The method is applicable to a wide variety of products and ingredients and uses uniform mechanical action to ensure accurate and reliable results. The vibrator reproduces the ci...

Embodiment 3

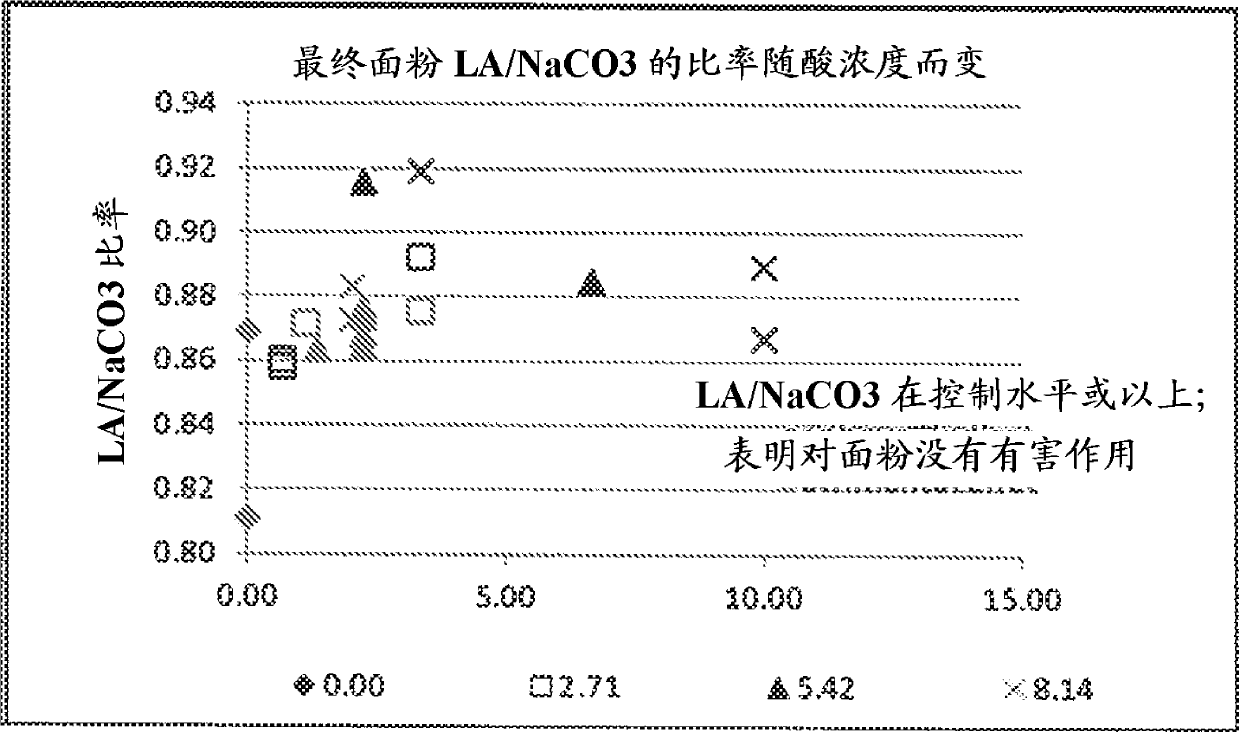

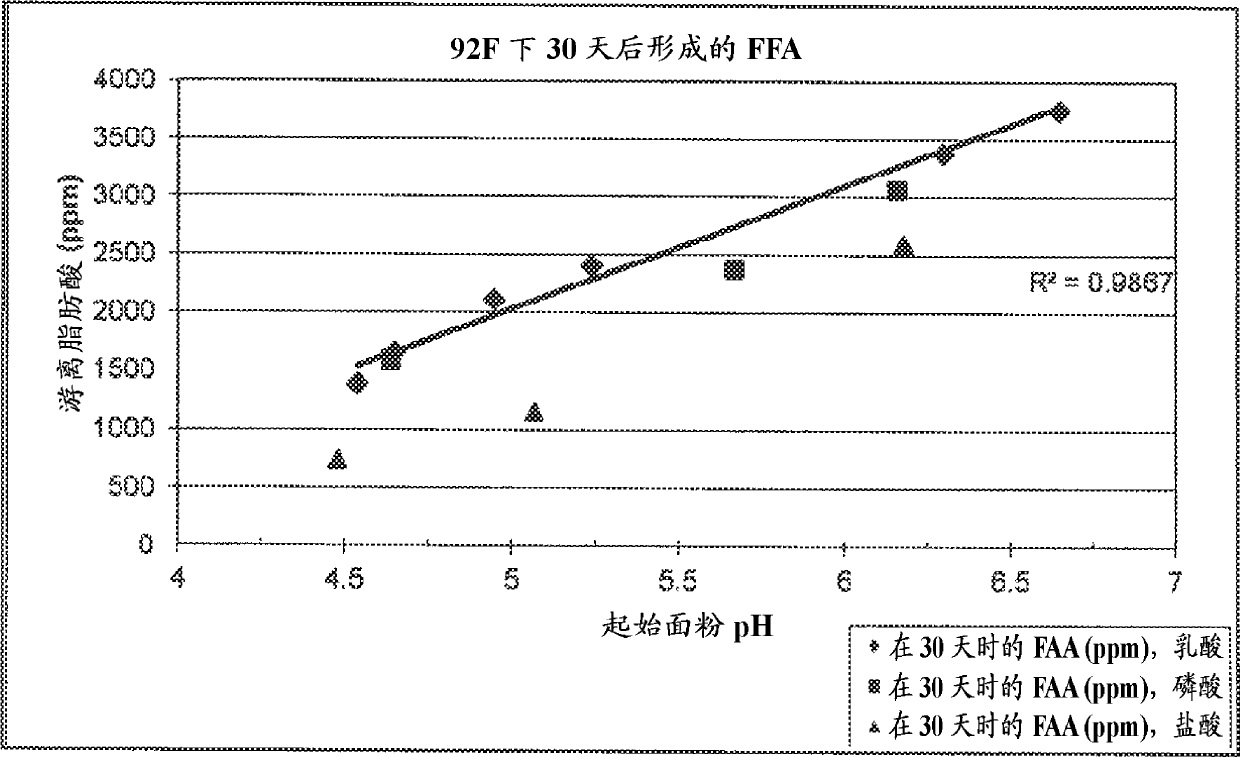

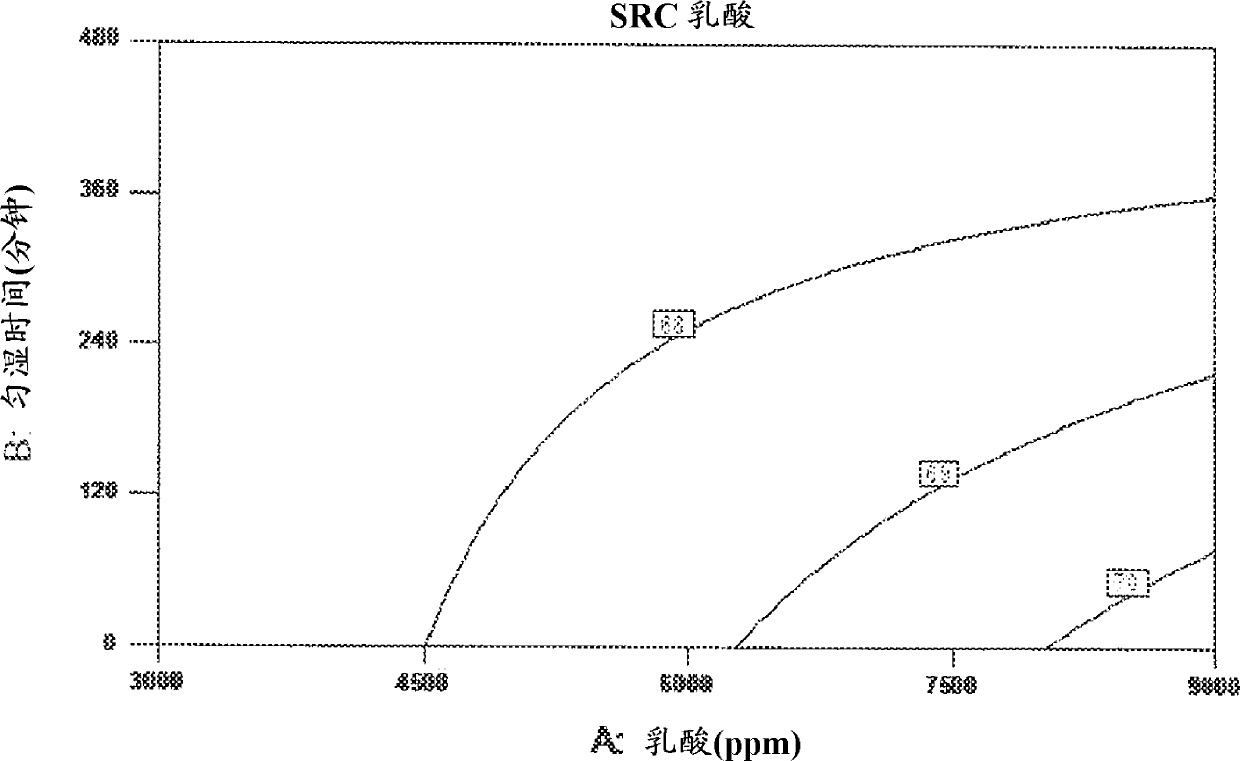

[0283] Effects of acid homogenization on the stability of whole grain flour

[0284] The objective of this example was to test the effect of acid conditioning on the stability of whole grain flour during storage. The amount of free fatty acid formed was determined after the flour was stored in a sealed glass jar for 30 days under accelerated storage conditions at 92°F. Whole grain flour was prepared as described in Examples 1 and 2. The flours tested were: (1) untreated soft red flour (control); (2) soft red flour treated with lactic acid to pH 6.30; (3) soft red flour treated with lactic acid to pH 5.24; (4) ) Soft red flour treated with lactic acid to pH 4.95; (5) Soft red flour treated with lactic acid to pH 4.65; (6) Soft red flour treated with lactic acid to pH 4.54; (7) Soft red flour treated with phosphoric acid to pH 6.16 soft red flour; (8) soft red flour treated with phosphoric acid to pH 5.67; (9) soft red flour treated with phosphoric acid to pH 4.64; (10) so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com