Double-rectifying-tower series separation and purification method for recovery of methyl tert-butyl ether-tetrahydrofuran in waste liquid in statins synthesis process

A technology for synthesizing methyl tert-butyl ether and drugs, which is applied in the field of separation and purification of double rectification towers in series, and can solve problems such as solvent waste, economic waste, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

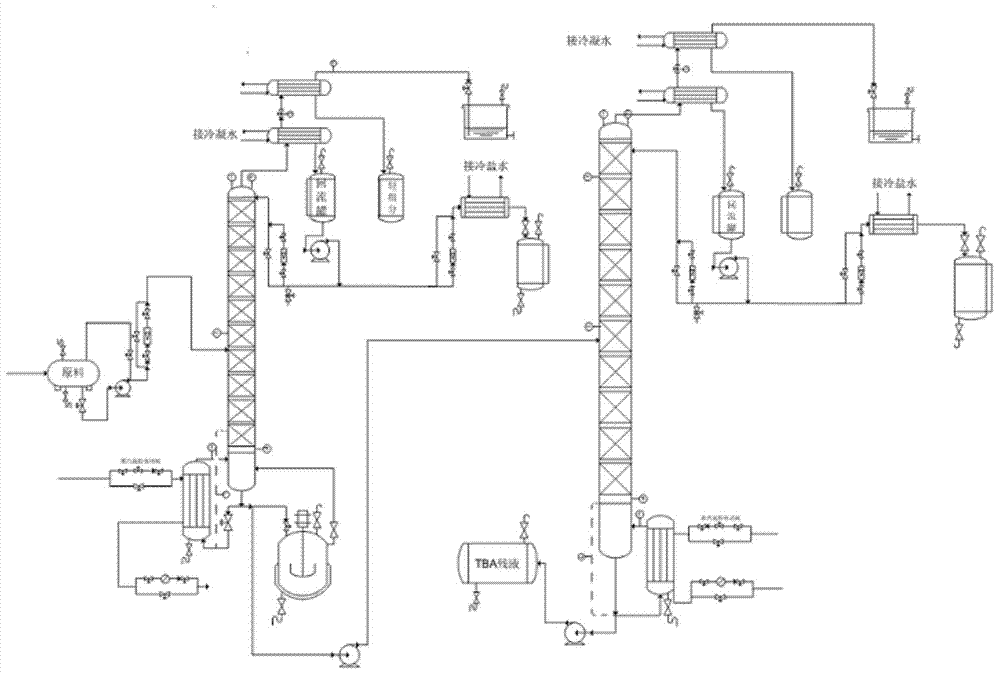

Image

Examples

Embodiment 1

[0023] There is a batch of process raw materials, its composition is isoprene 12.3%, methyl tert-butyl ether 51.2%, tetrahydrofuran 17.6%, tert-butyl acetate 18.4%, also contains 0.5% impurities, moisture content 2%. It was added to the I tower at a rate of 0.95 L / h, the reflux ratio was controlled to 2-4, the tower top temperature was controlled to 35° C., and the operating pressure of the whole tower was normal pressure. Through the above operations, a mixed solution of isoprene and water with relatively high purity can be obtained at the top of the tower, and high-purity isoprene can be obtained after layering. The composition of the tower kettle discharge liquid is 3.2% isoprene, 54.2% methyl tert-butyl ether, 20.5% tetrahydrofuran, 21.6% tert-butyl acetate, and the rest are impurities. The discharge from tower I of tower I enters from the middle and lower part of tower II, the feed rate is 0.36L / h, the reflux ratio is controlled at 0.3-1.0, the temperature at the top of t...

Embodiment 2

[0025]There is a batch of process raw materials, the composition of which is 16.5% of isoprene, 48.2% of methyl tert-butyl ether, 16.7% of tetrahydrofuran, 17.8% of tert-butyl acetate, and contains 0.8% of impurities, and the water content is 1.8%. It was added to the I tower at a rate of 0.95 L / h, the reflux ratio was controlled to 2-4, the tower top temperature was controlled to 35° C., and the operating pressure of the whole tower was normal pressure. Through the above operations, a mixed solution of isoprene and water with relatively high purity can be obtained at the top of the tower, and high-purity isoprene can be obtained after layering. The composition of the tower kettle discharge liquid is 3.7% of isoprene, 51.6% of methyl tert-butyl ether, 21.6% of tetrahydrofuran, 22.3% of tert-butyl acetate, and the rest are impurities. The discharge from tower I of tower I enters from the middle and lower part of tower II, the feed rate is 0.36L / h, the reflux ratio is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com