Bauxite desulphurization method and device

A desulfurization device, bauxite technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of large-scale industrial application of alumina, low leaching efficiency and high processing cost, and achieve continuous improvement. performance and stability, reducing investment costs and operating costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

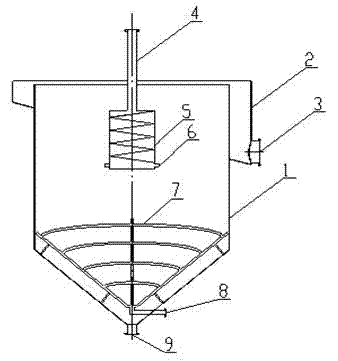

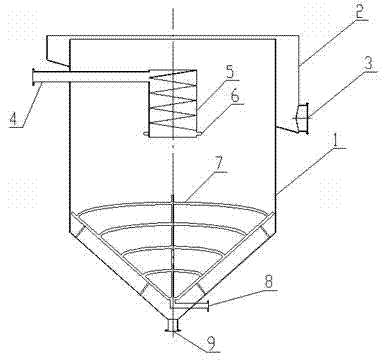

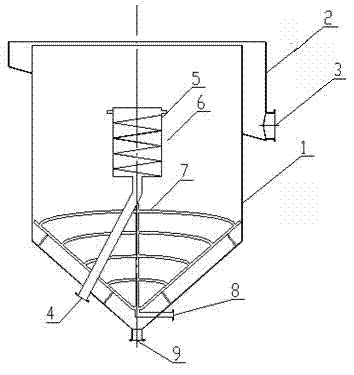

Image

Examples

Embodiment 1

[0034] Taking a high-sulfur bauxite ore under coal in a certain area of Henan Province as the test ore sample, the chemical composition of the ore is shown in Table 1.

[0035] Table 1 High-sulfur bauxite mine under coal in a certain area in Henan

[0036] ingredientAl 2 O 3 SiO 2 Fe 2 O 3 TiO 2 K 2 O Na 2 O CaO MgOSC Discretionary content / %63.4612.352.642.961.100.0250.810.251.211.8013.40

[0037] The test process consists of a section of rapid chemical desulfurization underflow in parallel with two of the equipments for bioleaching desulfurization.

[0038] Process parameters: rapid chemical desulfurization grinding fineness of 78%-200 mesh, natural pulp pH value, chemical desulfurization agent dosage 400g / t, desulfurization temperature is normal temperature; chemical desulfurization underflow enters the second stage mill through the discharge port to the grinding The fineness is 92% -200 mesh. After entering the stirring channel, inoculate Thiobacillus ferrooxidans, adjust ...

Embodiment 2

[0046] Taking a high-sulfur bauxite ore in Zunyi as the test ore sample, the chemical composition of the ore is shown in Table 3.

[0047] Table 3 High-sulfur bauxite mine in Zunyi

[0048] ingredientAl 2 O 3 SiO 2 Fe 2 O 3 TiO 2 K 2 O Na 2 O CaO MgOS Discretionary content / %65.617.976.192.881.220.040.130.141.6313.79

[0049] The test process consists of a section of rapid chemical desulfurization underflow in parallel with four of the equipments for bioleaching desulfurization.

[0050] Process parameters: rapid chemical desulfurization grinding with a fineness of 65%-200 mesh, natural pulp pH value, chemical desulfurization agent dosage 300g / t, desulfurization temperature at room temperature; chemical desulfurization underflow enters the second-stage mill through the discharge port to the grinding The fineness is 90% -200 mesh. After entering the stirring channel, inoculate Thiobacillus ferrooxidans, adjust the pH value of the slurry to 2.0, and use a pump to transfer to the 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com