Method for preparing high depth-diameter-ratio three-dimensional micro-channel through electronic dynamic control

A technology of electronic dynamic control and high depth-to-diameter ratio, which is applied in the field of femtosecond laser applications, can solve the problems of difficulty in processing three-dimensional microchannels with nanostructures in modified regions, and achieve the effect of improving the depth-to-diameter ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The femtosecond laser system 1 uses a laser produced by SpectraPhysics in the United States. The laser wavelength is 800nm, the pulse width is 50 femtoseconds, the repetition frequency is adjustable at 1KHz, the maximum energy of a single pulse is 3mJ, and the light intensity distribution is Gaussian and linearly polarized. .

[0027] Experimental sample 10 is fused silica with a thickness of 1 mm.

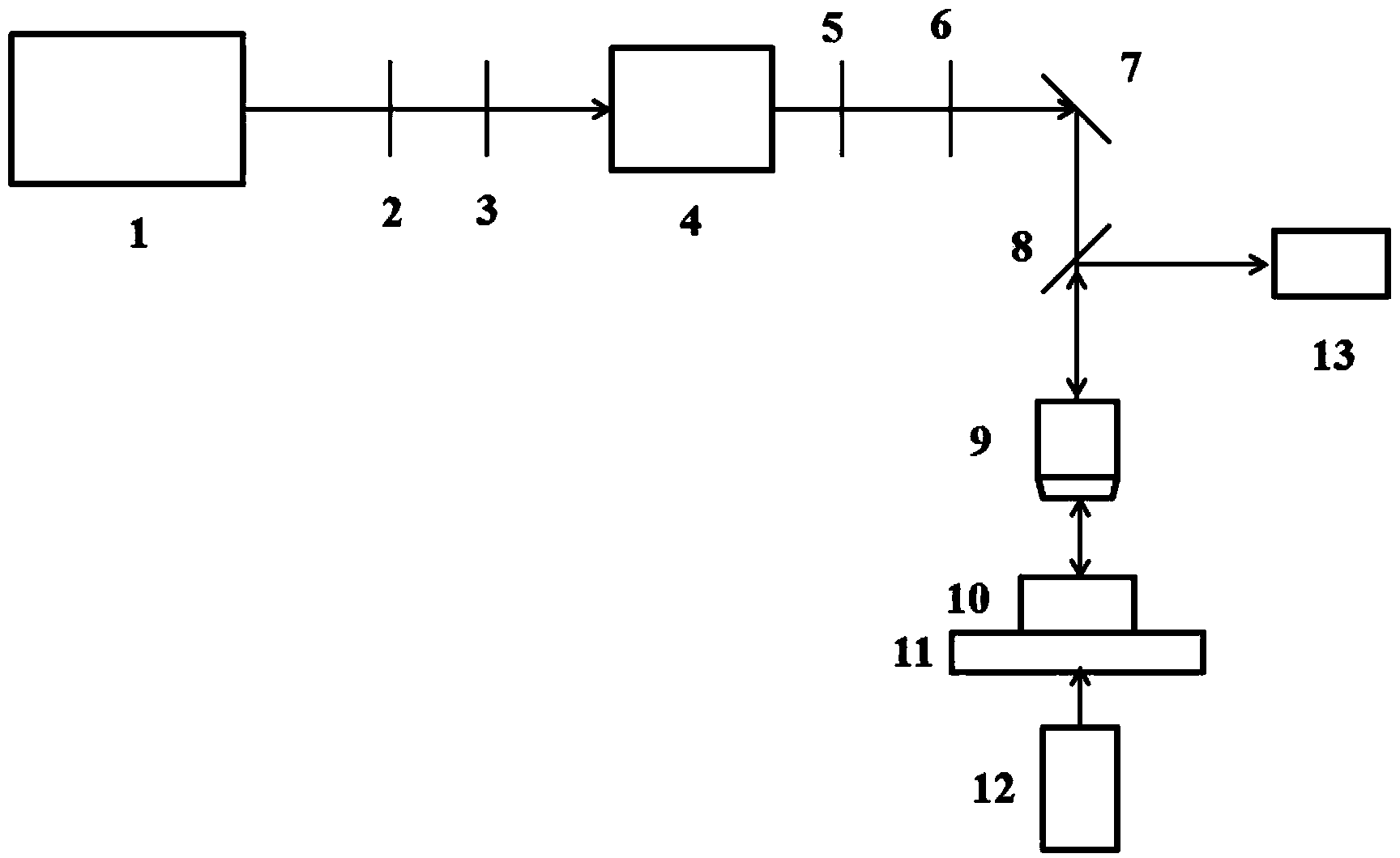

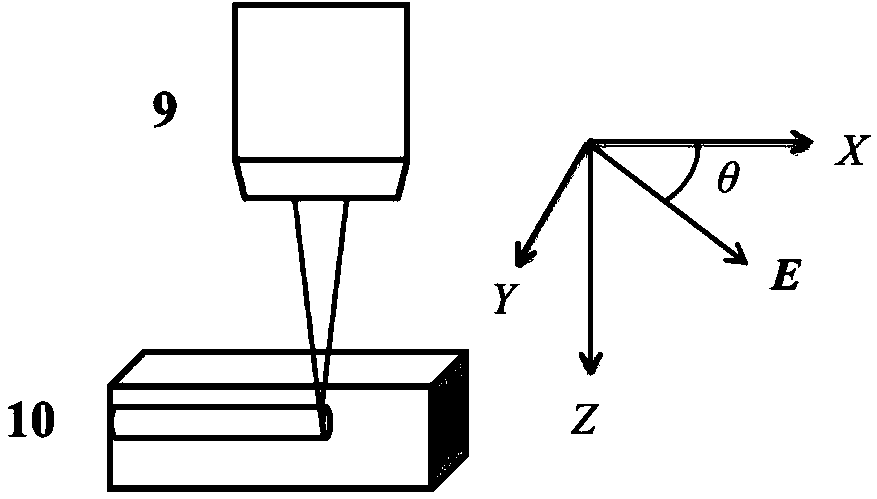

[0028] The present invention proposes a method for preparing a three-dimensional microchannel with a high depth-to-diameter ratio by using a femtosecond laser pulse sequence. The processing optical path is as follows: figure 1 As shown, the specific processing steps are as follows:

[0029] Step 1: Use femtosecond laser system 1 to generate femtosecond pulse laser, use the combination of half-wave plate 2 and polarizer 3 to adjust the single pulse energy to 0.5 μJ, and modulate the femtosecond laser into a pulse sequence through pulse shaper 4, the The sequence contains t...

Embodiment 2

[0035] The femtosecond laser system 1 uses a laser produced by SpectraPhysics in the United States. The laser wavelength is 800nm, the pulse width is 50 femtoseconds, the repetition frequency is adjustable at 1KHz, the maximum energy of a single pulse is 3mJ, and the light intensity distribution is Gaussian and linearly polarized. .

[0036] Experimental sample 10 is fused silica with a thickness of 1 mm.

[0037] The present invention proposes a method for preparing a three-dimensional microchannel with a high depth-to-diameter ratio by using a femtosecond laser pulse sequence. The processing optical path is as follows: figure 1 As shown, the specific processing steps are as follows:

[0038] Step 1: Use femtosecond laser system 1 to generate femtosecond pulse laser, use the combination of half-wave plate 2 and polarizer 3 to adjust the single pulse energy to 0.5 μJ, and modulate the femtosecond laser into a pulse sequence through pulse shaper 4, the The sequence contains two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com