Spraying paint wastewater treatment technology

A waste water treatment and waste water technology, applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of low cost of painting waste water, save business expenses and facilitate promotion effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

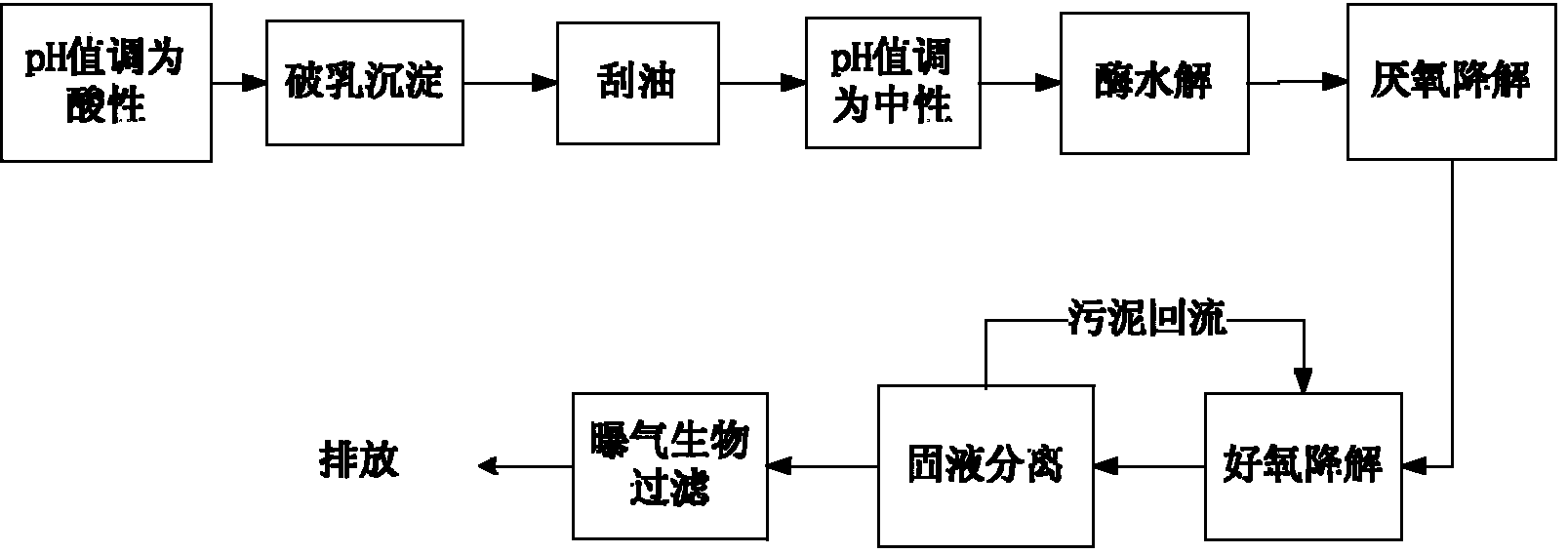

Method used

Image

Examples

Embodiment 1

[0041] 1. Dilute 1 ton of spray paint wastewater (COD Cr The concentration is 22630mg / L, pH=7) placed in the pH adjustment pool, add concentrated sulfuric acid, stir evenly, the pH value of the wastewater is 2, let it stand for 5 minutes, the oil-in-water system begins to disperse and destabilize, and the oil and water slowly separate to obtain acidification liquid;

[0042] 2. Pour the obtained acidified solution into the demulsification sedimentation tank, add 0.1g of tertiary amine cationic polyether reverse demulsifier, 2g of calcium chloride, and 1g of 5‰PAM in sequence for each liter of acidified solution, stir quickly and evenly, and let it stand After 20 minutes, the upper suspension was scraped off, separated and collected to obtain a broken emulsion. At this time, the broken emulsion COD Cr The concentration is 13790mg / L, pH=2.

[0043] 3. Add 1.5kg of sodium hydroxide to each ton of broken emulsion, stir evenly, and measure COD after standing for 5 minutes Cr The...

Embodiment 2

[0051] 1. Dilute 1 ton of spray paint wastewater (COD Cr The concentration is 22630mg / L, pH=7) placed in the pH adjustment pool, add concentrated sulfuric acid, stir evenly, the pH value of the wastewater is 3, let it stand for 5 minutes, the oil-in-water system begins to disperse and destabilize, the oil and water slowly separate, and the acidified solution is obtained ;

[0052] 2. Pour the obtained acidified solution into the demulsification sedimentation tank, add 5g of tertiary amine cationic polyether reverse phase demulsifier, 0.01g of calcium chloride, 5g of PAM with a concentration of 5g / L to each liter of the acidified solution, and stir quickly and evenly , after standing for 20 minutes, scrape off the oil in the upper suspension, separate and collect, and obtain a broken emulsion. At this time, the broken emulsion COD Cr The concentration is 13790mg / L, pH=3.

[0053] 3. Add 1.2kg of sodium hydroxide to each ton of broken emulsion, stir evenly, and measure COD aft...

Embodiment 3

[0061] 1. Dilute 1 ton of spray paint wastewater (COD Cr The concentration is 22630mg / L, pH=7) placed in the pH adjustment tank, add concentrated sulfuric acid, stir evenly, the pH value of the wastewater is 4, let it stand for 5 minutes, the oil-in-water system begins to disperse and destabilize, and the oil and water slowly separate to obtain acidified liquid ;

[0062] 2. Pour the obtained acidification solution into the demulsification sedimentation tank, add 2g of tertiary amine cationic polyether reverse phase demulsifier, 10g of calcium chloride, 5g of PAM with a concentration of 2g / L to each liter of acidification solution, and stir quickly and evenly. After standing still for 20 minutes, scrape off the oil in the upper suspension, separate and collect, and obtain a broken emulsion. At this time, the broken emulsion COD Cr The concentration is 13790mg / L, pH=4.

[0063] 3. Add 1.0kg of sodium hydroxide to each ton of broken emulsion, stir evenly, and measure COD after...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap