Method for producing sodium saccharin

A production method and technology of sodium saccharin, applied in the direction of organic chemistry, etc., can solve the problems of multiple production links, long production process routes, and high ammonia nitrogen emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

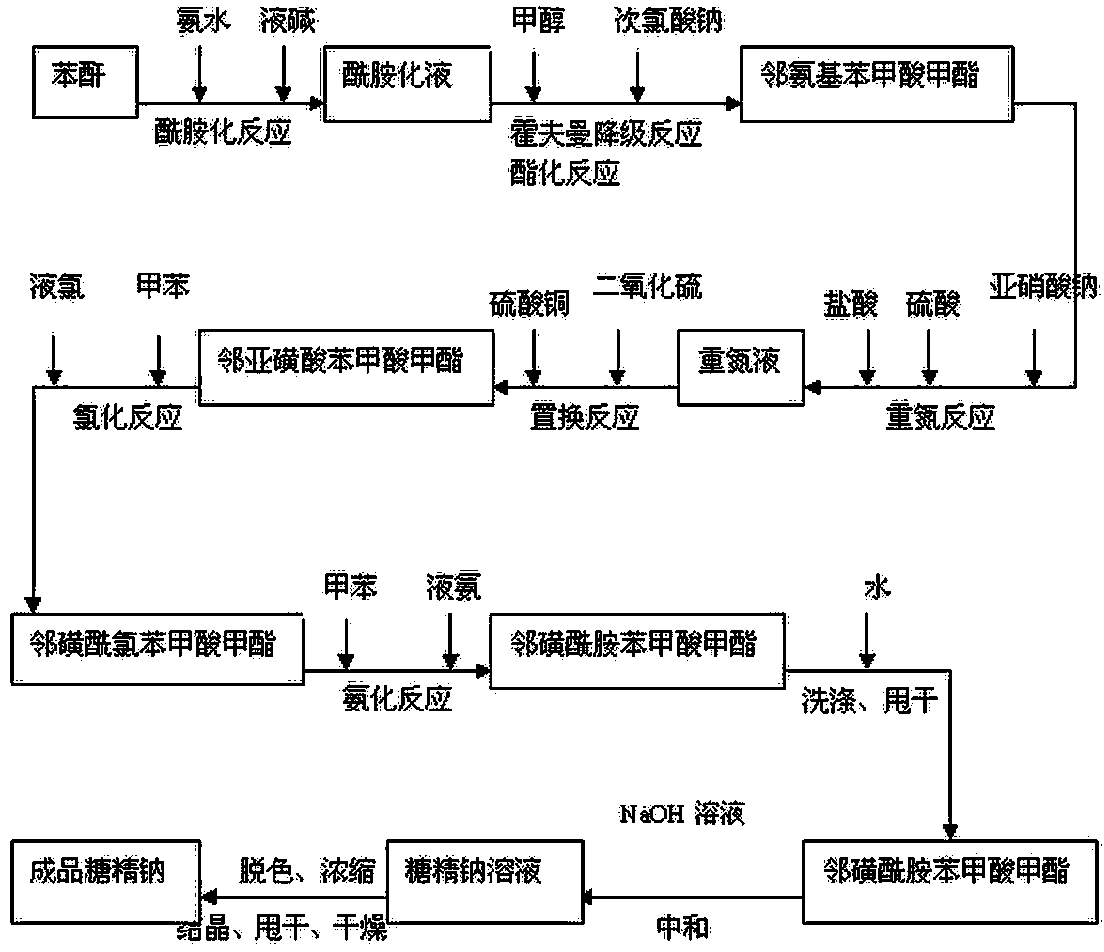

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] According to process flow chart, the concrete processing steps of production method of the present invention are as follows:

[0023] 1. Amidation reaction: Put ammonia water with a mass ratio of phthalic anhydride to ammonia water added in the amidation reaction kettle at a ratio of 1:0.1, start stirring, ventilate, and cool down with condensed brine at a temperature of about -15°C. When the temperature drops to about 0°C, open the baffle of the phthalic anhydride hopper and finish adding phthalic anhydride in about 10 minutes. The mass ratio of the amount of phthalic anhydride added to ammonia water is 1:0.1. When the temperature rises to 50-70°C and the pH value is 7, slowly add liquid caustic soda sodium hydroxide solution with a mass concentration of about 30%. When the pH value is 9, stop adding the sodium hydroxide solution, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com