One-pot dispersion polymerization for the preparation of non-spherical, raspberry-like or hollow polymer microspheres

A technology of dispersion polymerization and polymer, applied in the field of dispersion polymerization, to achieve the effect of obvious advantages and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

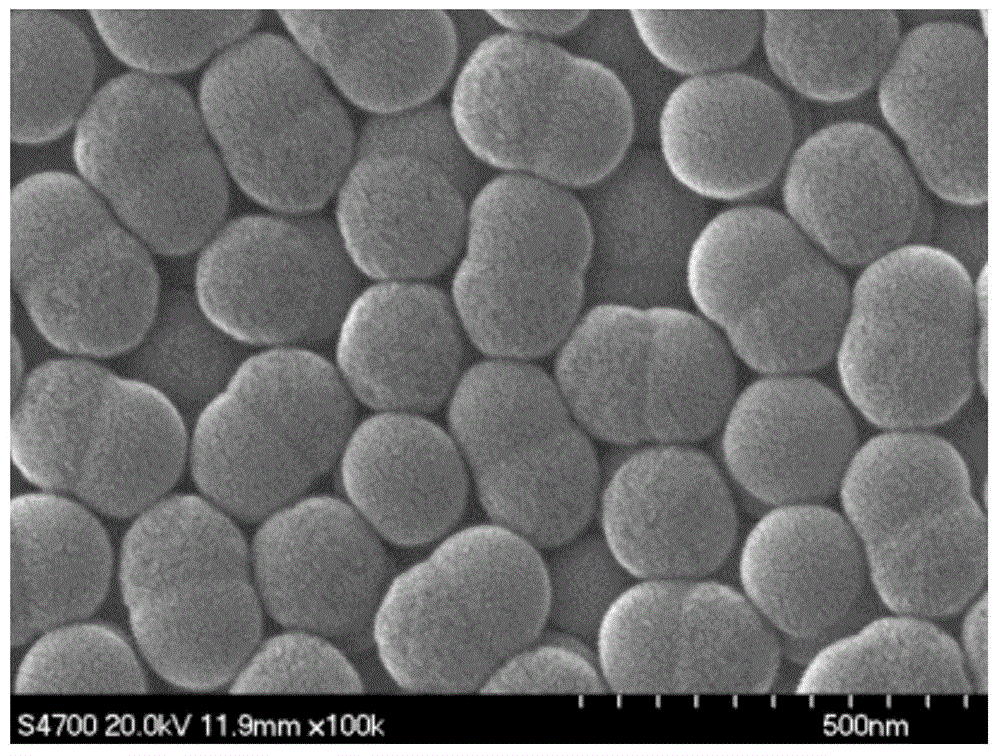

[0060] Place a 100ml four-necked round-bottom reaction flask equipped with mechanical stirring and reflux condenser in a constant temperature water bath, add 12.5ml of ethylene glycol and 12.5ml of deionized water (ethylene glycol / water=5 / 5, vol.) Add monomer styrene St 2.5ml (concentration 8wt.% in the reaction solution), sodium styrene sulfonate NaSS 0.0453g (2wt.%, relative to St weight), initiator azobisisobutyronitrile AIBN 0.0453g ( 2wt.%, relative to the weight of St); start stirring, the speed is 200r / min; 2 Deoxygenated for 30min and kept at N 2 Under the atmosphere, the constant temperature water bath was heated to 80°C at the same time to start the reaction. After 180min, add ATRP reagent CuBr to the reaction system 2 0.0138g (0.6wt.%, relative to the initial St weight) and MA 5 DETA0.0512g (2.3wt.%, relative to the initial St weight) and water 1ml (40vol.%, relative to the initial St volume), add cross-linking agent DBPMA 0.0906g (4wt.%, relative to the initial...

Embodiment 2

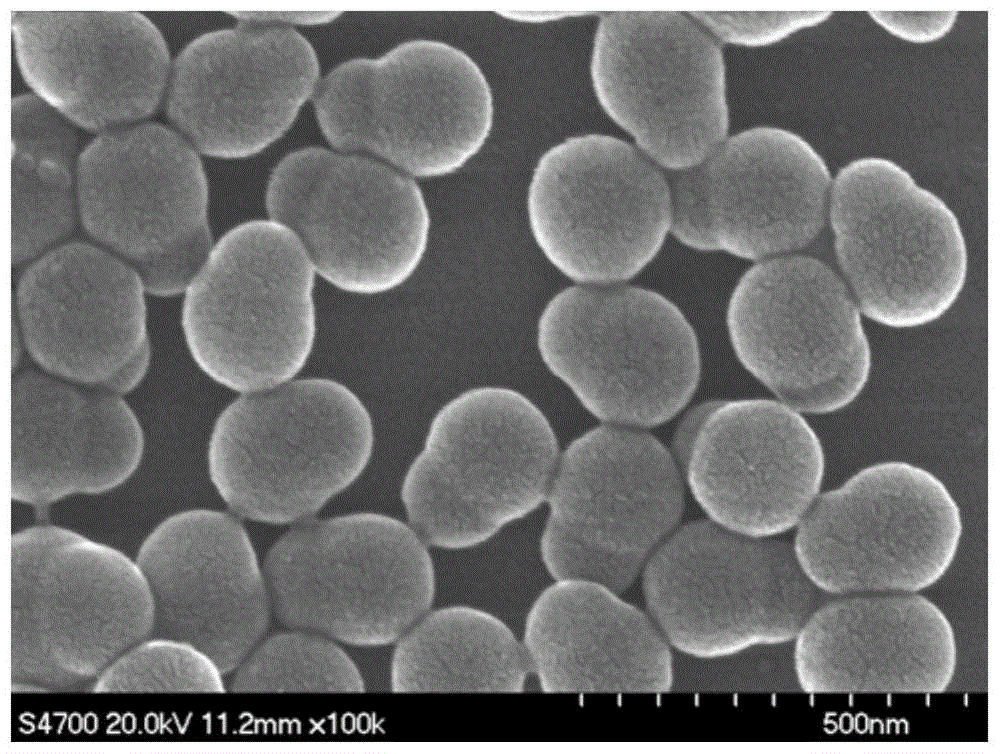

[0062] Others are as embodiment 1, just after dispersion polymerization reaction 180min, add cross-linking agent DBPMA 0.0906g (4wt.%, relative initial St weight) and DVB 1.6ml (65.4wt.%, relative initial St weight) to reaction system ), the microspheres observed by SEM are snowman-like polymer microspheres with smooth head and body surfaces (similar to the figure 1 ), the diameter of the head is 186nm, and the diameter of the body is 228nm.

Embodiment 3

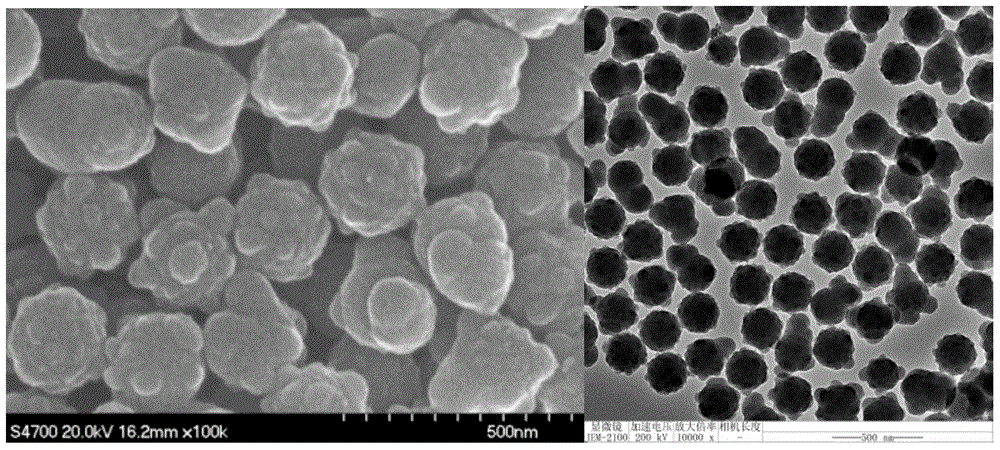

[0064] Others are as embodiment 1, just after dispersion polymerization reaction 180min, add MAEDCA 0.0138g (0.6wt.%, relative initial St weight) and water 1ml to reaction system, add cross-linking agent DBPMA0.0906g (4wt.%, relative Initial St weight) and DVB 1.6ml (65.4wt.%, relative to the initial St weight), continue to react for 5h. The microspheres observed by SEM and TEM are that the head surface is smooth and the body surface is very rough-the body is a raspberry-like snowman-like polymer microsphere (see the appendix figure 2 ), the head diameter is 130nm, and the body diameter is 233nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com