A frequency conversion electric drive top drive core drilling rig for geological coring exploration

A technology of core drilling rig and variable frequency power, which is applied in the direction of rotary drilling rig, percussion drilling, rotary drilling, etc. It can solve the limitation of mechanical vertical shaft core drilling rig's operating efficiency and operating safety performance, and its weak ability to deal with accidents in holes , Low transmission efficiency and other issues, to achieve the effect of efficiently and safely completing the drilling rig operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

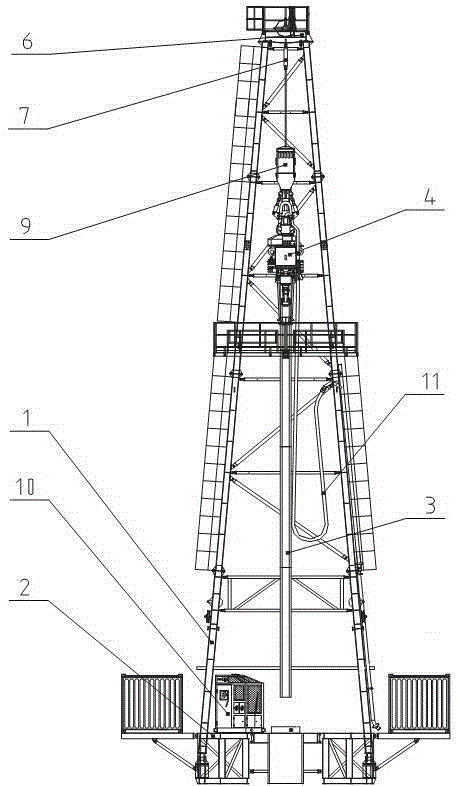

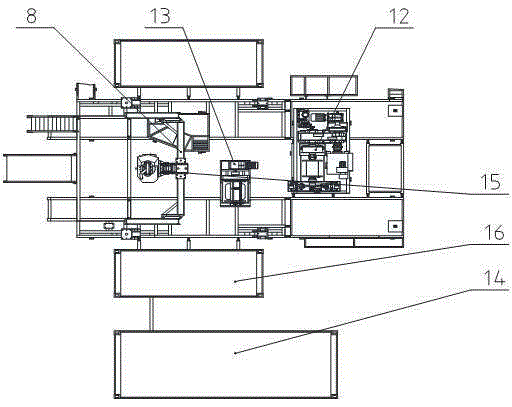

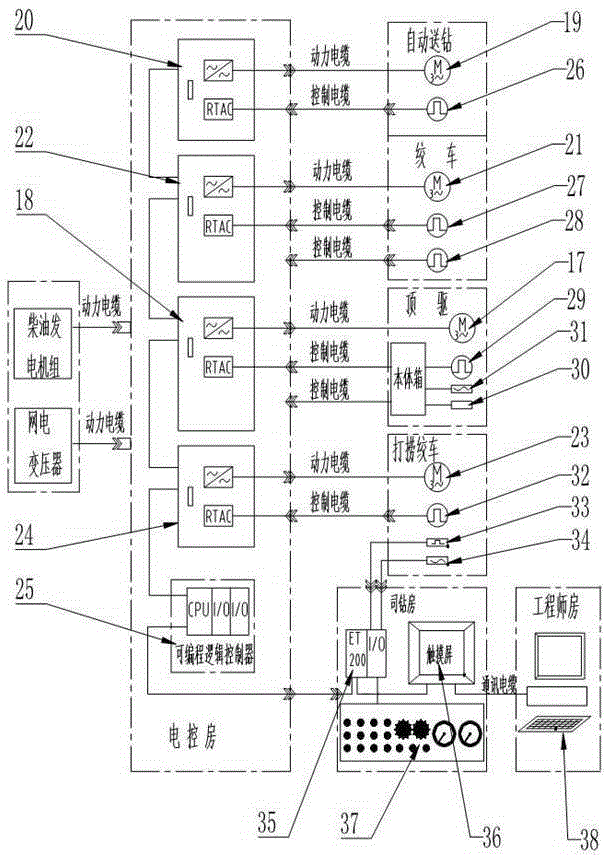

[0025] like figure 1 , figure 2 and image 3 As shown, the technical solution adopted by the present invention is an AC frequency conversion direct-drive top-drive core drilling rig for geological coring exploration. The drilling rig includes a platform 2 and a vertical derrick 1 on the platform 2. It is characterized in that the platform 2 An electric drive winch 12 and a salvage winch 13 are provided for retracting and unwinding ropes; a top drive guide rail 3 parallel to the derrick 1 is provided on the derrick 1, and the top drive guide rail 3 is connected to the AC frequency conversion direct drive top drive 4 through a bracket pulley 15; The AC frequency conversion direct drive top drive 4 adopts the top drive motor 17 to directly connect with the drill pipe through the connecting shaft; the motors of the AC frequency conversion direct drive top drive 4, the electric drive winch 12 and the salvage winch 13 are driven by the frequency converter in the electric control r...

Embodiment 2

[0027] On the basis of Example 1, in order to achieve high-speed drive drill pipe drilling and high-efficiency circulation of mud, a preferred embodiment of the present invention is that the top drive motor 17 is provided with a hollow central shaft, and the lower end of the central shaft is connected to the drill through a hollow connection shaft. Rod connection, the upper end of the center shaft is connected with the gooseneck through the faucet, and the drill pipe, the connecting shaft, the center shaft, the faucet and the gooseneck constitute a mud circulation system; in order to realize efficient control of the drilling rig operation, the driller’s cabin 10 is set on the platform 2, The outer surface of the platform 2 is provided with an electric control room 14, and the electric control room 14 is equipped with a power supply and a frequency converter. The station 35 is connected to the engineer room 16 through a communication cable; the power output terminals of the freq...

Embodiment 3

[0029] On the basis of Embodiment 2, in order to increase the operating stroke of the AC frequency conversion direct drive top drive 4 and improve the operating efficiency of the drilling rig, a preferred embodiment also includes a derrick crown block for hanging ropes at the top of the derrick 1 6. The derrick crane 6 is connected to the traveling block 9 through a rope, and the other end of the rope is connected to the winch 12; the traveling block 9 is suspended from the AC frequency conversion direct drive top drive 4; the suspension device 7 is used to hang the top drive guide rail 3; the derrick 1 The lower part is provided with an anti-torque beam, and the anti-torque beam is fixed on the support beam 8 at the back of the derrick; one end of the high-pressure mud pipeline 11 is suspended on the top of the AC frequency conversion direct drive top drive 4, and the other end is suspended on the side of the derrick 1, and the other parts are completely the same as in Embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com