Early waning method for rolling bearing of rotating machine

A technology of rolling bearings and rotating machinery, which is applied in the field of fault judgment devices to avoid economic losses, improve safety factors, and avoid nuclear leakage and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

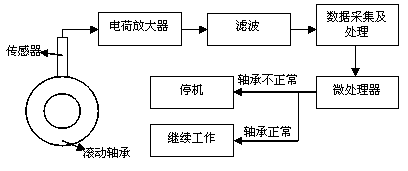

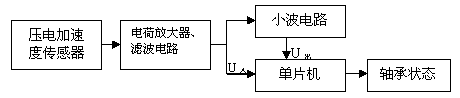

[0017] The vibration signal generated when the rolling bearing runs stably is a stable low-frequency signal, while the vibration signal generated when the bearing fails is a sudden high-frequency pulse signal. The wavelet algorithm is used to extract the position of the sudden high-frequency pulse point in the signal and output it through the early warning, which can be timely Intervene in the action of rotating machinery to ensure the safety of rotating machinery.

[0018] The real-time monitoring and early warning system of rolling bearing status mainly includes detection, amplification, filtering, signal acquisition and processing, signal output and alarm, such as figure 1 The schematic diagram of the structure of the early warning device for rolling bearings of rotating machinery is shown. Use the sensor to detect the vibration state of the rolling bearing, convert the mechanical quantity into electricity, collect the converted signal after amplification and filtering, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com