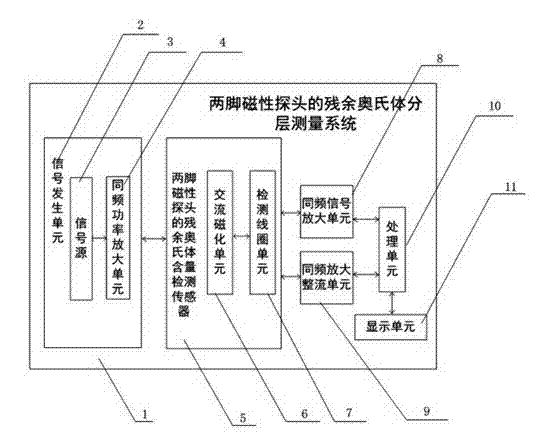

Two-pin magnetic probe layering detection system for residual austenite content

A residual austenite and measurement system technology, applied in the field of two-legged magnetic probe layered measurement system, can solve the problems of inconvenient test method, difficult detection, long detection cycle, etc., achieve layered measurement and reduce the cost of consumables , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The system 1 of the residual austenite layered measurement system of the two-legged magnetic probe utilizes the difference in magnetic properties between the ferromagnetic material retained austenite and martensite, and utilizes different frequencies of magnetization in the AC magnetization unit 6 The signal current performs AC magnetization on the measuring point, and then uses the detection coil unit 7 to extract the measured ferromagnetic material

[0022] The electrical signals of different frequencies due to the magnetic characteristic effect of the material measuring point are converted into magnetic parameters after being processed by the same-frequency signal amplification unit 8 and the same-frequency amplification and rectification unit 9 to convert them into magnetic parameters. The relationship between the penetration depth of the electromagnetic field and the frequency of the electromagnetic field, through the characterization and analysis of the magnetic pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com